Physical refining process of edible oil, what is physical refining of palm oil?

FAQ / Chat on line / Give me a price / Date: November 21, 2018

Edible oil refining is a relatively complex and flexible process. It is necessary to choose the appropriate edible oil refining method according to the purpose of oil refining, taking into account technical conditions and economic benefits. In general , edible oil refining methods can be diovided into : Mechanical method, chemical method and physical and chemical method. Today we mainly introduce the physical refining method of edible oil.

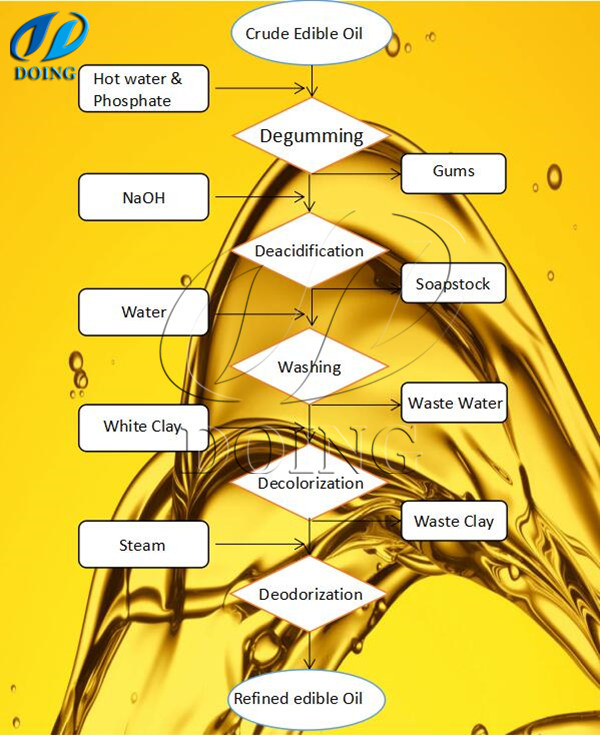

Edible oil refining process flow chart

Edible oil refining process flow chart

What is physical refining of palm oil?

Physical refining is also known as steam refining. In degumming process, it utilizes citric acid or food grade phosphoric acid to remove natural gums in the form of phosphatides. Then, in bleaching process, under vacuum, Fuller’s Earth is used to remove colouring matters and adsorb any metal ions. The deacidification and deodorization process is under high temperature and low pressure. By used of live steam, the FFA is stripped of. The steam is then recovered together with the entrained oil is as palm fatty acid distillate. The off-flavors and odours can also be removed from the crude palm oil in the steam distillation process. Before polishing, the refined oil needs to be cooled to 55°C.

Physical refining machine of edible oil

Physical refining machine of edible oil

What is the features of edible oil physical refining?

(1) The consumption of auxiliary materials is small, which reduces the pollution of wastewater to the environment. Deacidification by distillation can directly obtain fatty acids. No alkali is used, no soap is formed, and the oil does not have to be washed. It is no longer necessary to use acid to deacidify the soap to prepare fatty acids. Sewage due to acid-base treatment is avoided.

(2) The physical refining process is simple and the equipment is small. The deacidification and deodorization are combined into one process in the same equipment; the oil is not washed with water; the soap foot treatment section is omitted, thereby simplifying the physical refining process and reducing the equipment cost.

(3) High edible oil refining rate. There is no neutral oil saponification loss and emulsification loss. The higher the acid value, the more obvious this advantage. By physical refining process, edible oil loss can be reduced to below 1.05% to 1.1%.

(4) The product quality is good. The product oil has good stability, and the fatty acid (containing 85% to 90% free fatty acid) directly obtained during distillation is superior to the fatty acid obtained by acid hydrolysis and distillation after alkali refining.

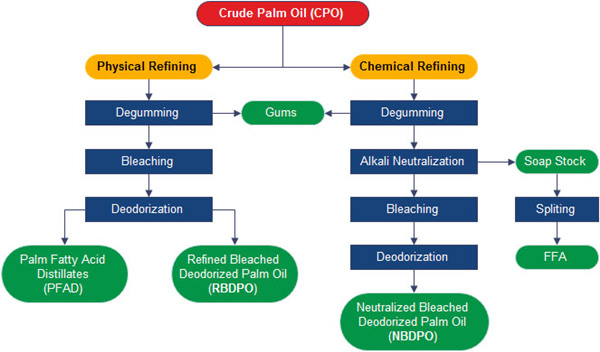

Chemical refining and physical refining of edible oil

Chemical refining and physical refining of edible oil

But physical refining of edible oil there are limitations. Chemical refining of edible oil is almost always available for all edible oils. Physical refining of edible oil does not suitable for all crude edible oil. It is suitable for the refining of low gum and high acid fats. When the free fatty acid content in the oil is below 2%, the advantages of physical refining are not obvious, and sometimes the operating cost is higher than that of alkali refining. But for palm oil refining , physical refining process is the first choice.

After reading this, i believe you have know the features of edible oil physical refining methods, hope you can choose suitable for edible oil refining methods during edible oil refining process.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line