HomeProductPalm oil refineryPalm oil refinery plant/palm oil fractionation and crystallization process

HomeProductPalm oil refineryPalm oil refinery plant/palm oil fractionation and crystallization process

Palm oil refinery plant/palm oil fractionation and crystallization process

Palm oil refinery / Chat on line / Give me a price / Date: October 17, 2017

Palm Oil is largely produced in equatorial belt, with Malaysia and Indonesia being the leading producers. Crude Palm Oil is dark in color and to make it edible it has to be refined. The Henan Doing Company Palm Oil Refinery Plant is best suitable to refine the palm oil. Our palm oil refinery plant refines the crude red palm oil and transforms it into edible refined transparent oil. The series of refining processes are conducted in our palm oil refinery plant. At every stage of refining, the palm oil changes its state and improves its quality.

We can supply and export the complete palm oil refinery plant with capacities ranging from 5 ton per day to 500 tons per day.

Palm oil refinery plant

Crude Palm Oil (CPO) Standard Specifications:

FFA ( as of Palmatic): 8% Maximum

Moisture & Impurities: 0.25% Maximum

Iodine Value: 56 Minimum

Melting Point: 36 - 50 deg. Maximum

DOBI: 2.31 Minimum

Cloud point: 3.5R 3.5Y

Process for Palm Oil Refinery Plant

Apart from all the regular refining procedures, there are two main additional processes that need to be carried out for refining crude palm oil:

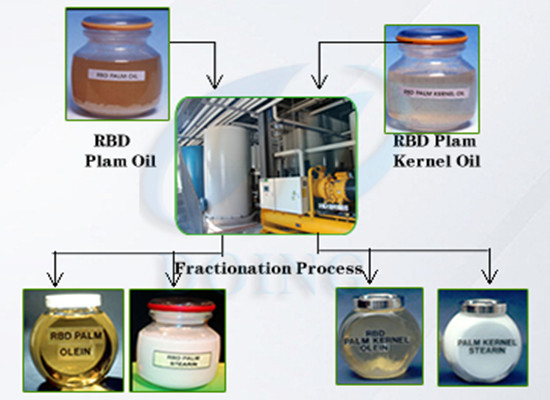

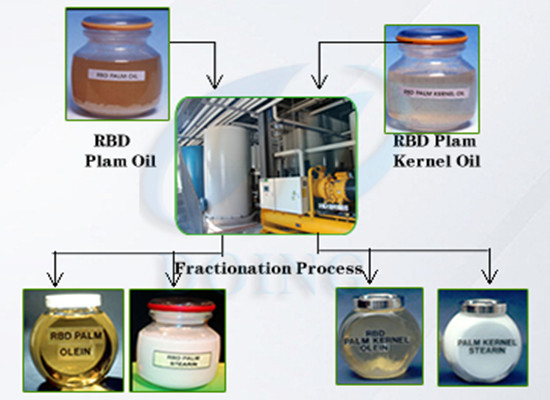

Fractionation process

Crystallization process

For crude palm oil refinery plant, fractionation process is required in which palm olein and palm stearin are separated by scientifically cooling the refined palm oil by chilling plant and then filtering the oil. For this purpose crystallizing vessel is used in which chilling pipe coils cool the oil for fractionation. Palm stearin crystals are formed due to chilling which are separated in the filter press and pure liquid of palm olein is obtained and palm stearin cake is retained in the filter press.

Palm oil fractionation plant

Fractionation Process Description:

Palm oil fractionation process is used to separate the palm olein and palm stearin from the RBDPO (Refined, Bleached, Deodorized Palm oil) produced by physical /chemical treatment. The RBDPO is further passed through the fractionation process to get various grade of palm olein and palm stearin. Usually, there are three types of olein are produced:

(1) Normal grade olein,

(2) Super grade olein

(3) Olein with cloud point 7 – 8°C.

Crystallization Process:

Firstly, the RBDPO feed must pass the quality specification, colour <2.6R and FFA < 0.075 is fed into the heat exchanger. The RBDPO feed is heated up by hot waters around 75°C.

After that the oil is kept homogenized at about 70°C in homogenizes before the start of crystallization. The idea is to destroy any crystals present and to induce

crystallization in a controlled manner in the crystallizer.

After that, the oil is pumped to the crystallizer. The crystallization system is a batch type and is equipped with special crystallizer operating batch wise. This crystallizer is made up of vertical cylindrical vessel full of thermo-regulated water which submerged barrels containing the oil to be fractionated: each of these barrels is fitted with a mechanical agitator. An automatic station controls the temperature in the crystallizer.

The crystallization process is carried out to remove the higher melting glycerides which cause liquid oils to become cloudy and more viscous at low temperature. There are 3 factors (temperature, time and agitation), have a fundamental importance on the formation and character of the crystal:

The lowering of temperature causes, because of supersaturating the higher melting component to separate from a solution.

Agitation facilitates the formation of small crystals.

Time with a gradual decrease in temperature and stillness, promotes the formation of longer crystals.

The solution is pumped batch-wise into the crystallizer according to a pre-established programme. In the crystallizer, the crystal formation and growth occurs as the oil is agitated and cooled sing chilled water and cool water filled in the jackets or cooling coils of the crystallizer. Cooling can be governed by controlling either the oil or water temperature.

Final Filtration Process:

After the crystallization process, the slurry from buffer tank passes through (Screw pump) the filtration process for the physical separation between RBD palm stearin and RBD palm olein. Presently, the membrane filter is used for this filtration. Another alternative for this purpose is by employing plate & frame type filter press with plates/frames made up of virgin polypropylene, this filter press provided with hydraulic closing device.

The membrane filter is pressure filter where the filter pack comprising alternatively plates and frames, or a series of chamber is compressed between one fixed and one movable cover or bulk-head. The filter media are located between each individual element. Cake will build up in the hollow space between the elements and fall out of the press when the filter pack is opened. Composition of the filter pack is by means of electrically driven hydraulic system (75 bar), which controls the entire mechanical parts of units, head plates, filter plates, plate shifting device with the built in panel board.

Thermic Fluid Heater, Steam boiler, Vacuum Pump, Steam jet ejector / booster, Barometric Condenser & Tower, Catchalls, Cooling tower, Water softening plant, Steam Generator, Soap pan,2 –Control Panels, Oil tanks (Raw, Bleached & Refined) etc. play their role in the refining process. So these equipments are part of the refinery and connected with the vessels through pipelines. All of these equipments are fitted accordingly at their respective place in the steel structure, which is supplied by us. We go for installation and commissioning of complete edible oil refinery plant.

We supply and export Palm Oil Refinery Plants along with its various equipments and technology to ensure that best finished palm oil is achieved with the lowest production cost.

We can supply and export the complete palm oil refinery plant with capacities ranging from 5 ton per day to 500 tons per day.

Palm oil refinery plant

Crude Palm Oil (CPO) Standard Specifications:

FFA ( as of Palmatic): 8% Maximum

Moisture & Impurities: 0.25% Maximum

Iodine Value: 56 Minimum

Melting Point: 36 - 50 deg. Maximum

DOBI: 2.31 Minimum

Cloud point: 3.5R 3.5Y

Process for Palm Oil Refinery Plant

Apart from all the regular refining procedures, there are two main additional processes that need to be carried out for refining crude palm oil:

Fractionation process

Crystallization process

For crude palm oil refinery plant, fractionation process is required in which palm olein and palm stearin are separated by scientifically cooling the refined palm oil by chilling plant and then filtering the oil. For this purpose crystallizing vessel is used in which chilling pipe coils cool the oil for fractionation. Palm stearin crystals are formed due to chilling which are separated in the filter press and pure liquid of palm olein is obtained and palm stearin cake is retained in the filter press.

Palm oil fractionation plant

Palm oil fractionation process is used to separate the palm olein and palm stearin from the RBDPO (Refined, Bleached, Deodorized Palm oil) produced by physical /chemical treatment. The RBDPO is further passed through the fractionation process to get various grade of palm olein and palm stearin. Usually, there are three types of olein are produced:

(1) Normal grade olein,

(2) Super grade olein

(3) Olein with cloud point 7 – 8°C.

Crystallization Process:

Firstly, the RBDPO feed must pass the quality specification, colour <2.6R and FFA < 0.075 is fed into the heat exchanger. The RBDPO feed is heated up by hot waters around 75°C.

After that the oil is kept homogenized at about 70°C in homogenizes before the start of crystallization. The idea is to destroy any crystals present and to induce

crystallization in a controlled manner in the crystallizer.

After that, the oil is pumped to the crystallizer. The crystallization system is a batch type and is equipped with special crystallizer operating batch wise. This crystallizer is made up of vertical cylindrical vessel full of thermo-regulated water which submerged barrels containing the oil to be fractionated: each of these barrels is fitted with a mechanical agitator. An automatic station controls the temperature in the crystallizer.

The crystallization process is carried out to remove the higher melting glycerides which cause liquid oils to become cloudy and more viscous at low temperature. There are 3 factors (temperature, time and agitation), have a fundamental importance on the formation and character of the crystal:

The lowering of temperature causes, because of supersaturating the higher melting component to separate from a solution.

Agitation facilitates the formation of small crystals.

Time with a gradual decrease in temperature and stillness, promotes the formation of longer crystals.

The solution is pumped batch-wise into the crystallizer according to a pre-established programme. In the crystallizer, the crystal formation and growth occurs as the oil is agitated and cooled sing chilled water and cool water filled in the jackets or cooling coils of the crystallizer. Cooling can be governed by controlling either the oil or water temperature.

Final Filtration Process:

After the crystallization process, the slurry from buffer tank passes through (Screw pump) the filtration process for the physical separation between RBD palm stearin and RBD palm olein. Presently, the membrane filter is used for this filtration. Another alternative for this purpose is by employing plate & frame type filter press with plates/frames made up of virgin polypropylene, this filter press provided with hydraulic closing device.

The membrane filter is pressure filter where the filter pack comprising alternatively plates and frames, or a series of chamber is compressed between one fixed and one movable cover or bulk-head. The filter media are located between each individual element. Cake will build up in the hollow space between the elements and fall out of the press when the filter pack is opened. Composition of the filter pack is by means of electrically driven hydraulic system (75 bar), which controls the entire mechanical parts of units, head plates, filter plates, plate shifting device with the built in panel board.

Thermic Fluid Heater, Steam boiler, Vacuum Pump, Steam jet ejector / booster, Barometric Condenser & Tower, Catchalls, Cooling tower, Water softening plant, Steam Generator, Soap pan,2 –Control Panels, Oil tanks (Raw, Bleached & Refined) etc. play their role in the refining process. So these equipments are part of the refinery and connected with the vessels through pipelines. All of these equipments are fitted accordingly at their respective place in the steel structure, which is supplied by us. We go for installation and commissioning of complete edible oil refinery plant.

We supply and export Palm Oil Refinery Plants along with its various equipments and technology to ensure that best finished palm oil is achieved with the lowest production cost.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line