Why is palm oil deacidified during the refining process? How to perform deacidification?

FAQ / Chat on line / Give me a price / Date: March 26, 2024

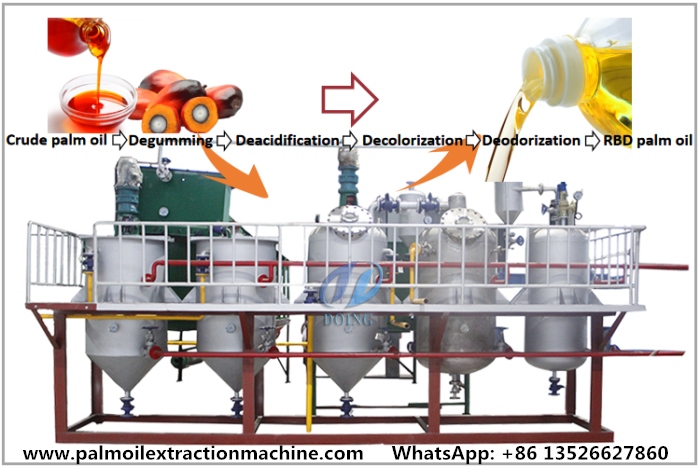

Palm oil, a staple in the global edible oils market, undergoes an intricate palm oil refining process to ensure its suitability for consumption and commercial use. One of the critical stages in palm oil refining process is palm oil deacidification process, which plays a significant role in enhancing the palm oil's quality, stability, and safety. But why exactly is palm oil deacidified, and how is palm oil deacidification process carried out? Next I will introduce it to you in detail.

Complete palm oil refining machine

Complete palm oil refining machine

The importance of palm oil deacidification process:

Palm oil deacidification process is necessary because crude palm oil naturally contains free fatty acids (FFAs), which are the byproducts of the palm oil extraction process. These FFAs contribute to the palm oil's acidity level, which can negatively affect its taste, odor, and shelf life. High acidity levels can make the palm oil go rancid more quickly, leading to off-flavors and reduced nutritional value.

Moreover, high levels of FFAs can pose health risks if consumed excessively. Therefore, lowering the acidity through palm oil deacidification process not only improves the palm oil's qualities but also ensures it meets safety standards.

The palm oil deacidification process:

The palm oil deacidification process typically involves a chemical refining method that utilizes an alkaline solution to neutralize the FFAs. Here's a stepwise breakdown of the palm oil deacidification process:

1.Pretreatment:

Before palm oil deacidification process, the crude palm oil undergo pretreatment processes such as degumming to remove impurities like phospholipids.

Palm oil deacidification and degumming process

Palm oil deacidification and degumming process

2. Alkaline Neutralization:

The actual palm oil deacidification process involves adding an alkali, usually sodium hydroxide (caustic soda), to the palm oil. This chemical reacts with the FFAs to form soapstock—a mixture of fatty acid salts that are insoluble in oil.

3. Separation:

The soapstock is then separated from the palm oil through centrifugal forces or by settling and filtration. This leaves behind a refined palm oil with significantly reduced FFA content.

4. Washing:

After separation, the palm oil may be washed with water to remove any residual alkali and trace soapstock, ensuring the purity of the final product.

5. Bleaching and Deodorization:

Following palm oil deacidification process, the palm oil is often bleached using activated earth to remove any remaining color bodies. Subsequently, it undergoes deodorization to eliminate undesirable odors, leaving a bland and stable oil suitable for various uses.

Deodorization machine in palm oil refining process

Deodorization machine in palm oil refining process

6. Quality Control:

Throughout the palm oil extraction process, stringent quality control measures are implemented to ensure the oil meets specific standards for acidity, and other indicators of quality and safety.

In summary, palm oil deacidification process is a crucial step in the palm oil refining process. It is performed to inhibit the growth of FFAs, which would otherwise compromise the palm oil's quality and safety. As a professional edible oil processing machine manufacturer, we can customize a suitable palm oil refining process for you based on your needs and investment costs. It should be noted that palm oil refining machine is a unified whole, and it cannot be selected for a certain section. It is impossible to obtain palm oil that meets national standards by only processing a certain section of the palm oil refining process. If you need palm oil refining machine, you can contact us.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line