Traditional VS Mechanized Palm Kernel Oil Extraction Methods

Industry news / Chat on line / Give me a price / Date: November 30, 2022

This article mainly introduces the traditional and mechanized palm kernel oil extraction methods, so that everyone can understand these two extraction methods in detail. At the same time, by comparison, we can find the advantages of mechanized production.

Traditional palm kernel oil extraction method:

Traditional palm kernel oil processing

Traditional palm kernel oil processing

Traditional palm kernel oil processing begins with the shelling of the palm kernel. The old-fashioned way of separating the kernel and shell for shelling is to use two stones to squeeze and crack each nut. This manual operation has largely been replaced by the use of palm kernel cracker.

Traditional kernel shell separation is usually performed in a clay bath, which is a concentrated viscous mixture of clay and water. The clay bath uses density to cause the shell to sink and the lighter palm kernel to float to the top. Use a basket to scoop up the floating nuts, wash them with water, and dry them in the sun. Intermittently and periodically, scoop out sunken shells from the bath and discard.

Oil is traditionally extracted by frying old palm kernels or simply heating the dried kernels. The fried palm kernels are then mashed or ground into a paste in an electric grinder. Mix the paste with a little water and heat to release the palm kernel oil. Periodically skim off the released oil from the topand crude palm kernel oil is obtained through sedimentation and oil skimming for a certain period of time.

Mechanized palm kernel oil extraction method:

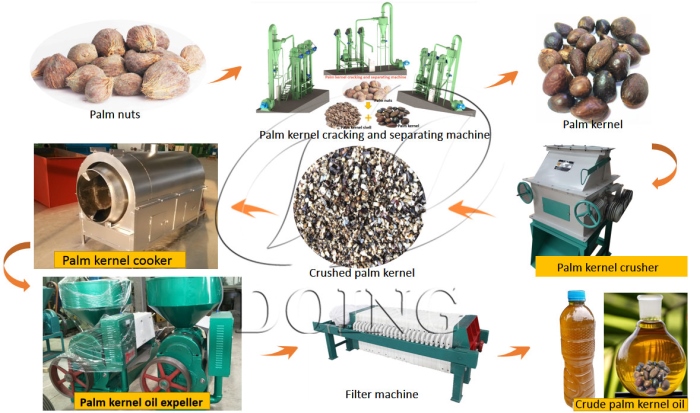

The mechanical extraction process is suitable for palm kernel oil extraction with various processing volumes. The following mainly talks about the extraction method of palm kernel oil from pretreatment, pressing and filtration.

Mechanical palm kernel oil extraction process

Mechanical palm kernel oil extraction process

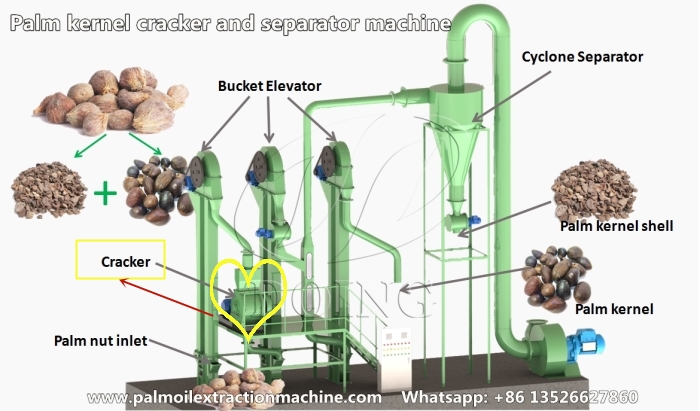

Mechanized palm kernel oil extraction begins with pretreatment. The first step begins with fiber separation, where the outer fibers of the palm kernel are stripped. Then the shell separation system, which first passes through the magnetic separator is usually used to remove metal matter, because these matter may damage the screw press and increase maintenance costs. In the next step, use the cracker to break the fruit core through impact and friction, and then wind the separation column to separate the kernels and shells according to the weight of the kernels and shells; the cyclone separator can prevent the shells from flying randomly, which can be selected according to budget needs and elect separately. In the second step, the crusher is used to crush the palm kernel, because the kernel is very hard, and the crushing can increase the contact area with the oil press for better pressing and extraction of oil. The third step is use the cooker to adjust the temperature and water to soften the palm kernel and increase the oil yield.

Palm kernel cracker and separator machine

Palm kernel cracker and separator machine

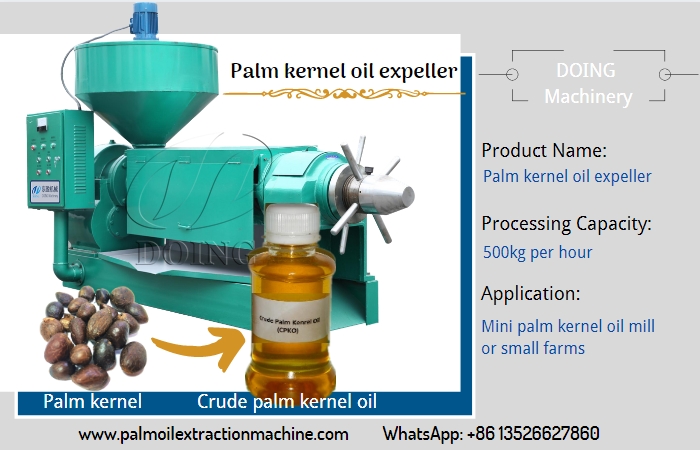

Secondly, the pressing part of the palm kernel extraction method. The palm oil press machine is oil press machine specially manufactured by Henan Glory Company for pressing palm kernels. The main part is composed of a power unit, a feeding port, a pressing chamber and a pressing screw. Appropriate amount of palm kernels are sent into the press chamber of the screw oil press from the feed port, with the snail in the middle. It rotates in a fixed perforated cylinder called a cage or barrel, and the volume of the axial displacement of the worm decreases gradually from the feed end to the discharge end. Through continuous rotation, the palm kernels are continuously pressed. The discharged oil is discharged through the perforation of the barrel liner, and the deoiled filter cake is discharged through the annular hole. In order to prevent extreme temperatures that may damage oil and cake quality, the worm shaft is always cooled with circulating water, while the barrel is cooled externally by recycling some cooling oil.

Palm kernel oil presser

Palm kernel oil presser

Finally the filtering part of the palm kernel. Simply filter through the plate and frame filter, and the crude oil passes through layers of filter cloth to filter scum and some impurities. Through this step, relatively clean crude palm kernel oil can be obtained, and then put into the crude oil storage tank for temporary storage. If one wants to obtain edible refined palm kernel oil, the crude palm kernel oil needs to be degummed, deacidified, decolorized and deodorized. Henan Glory Company can also provide three types of refining equipment, and customers can choose according to the processing capacity.

Advantages of using mechanized palm kernel oil extraction method:

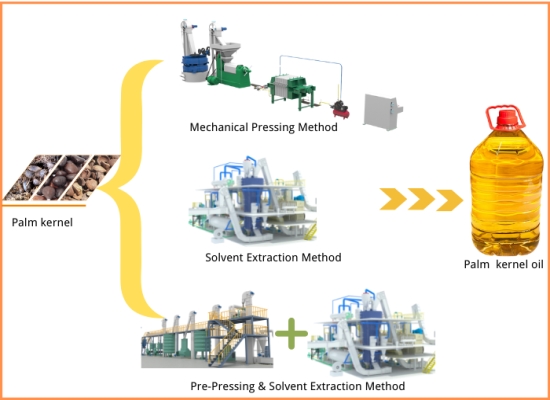

Palm kernel oil extraction methods

Palm kernel oil extraction methods

1. The use of machine production greatly reduces labor costs and has higher production efficiency.

2. The degree of automation of mechanized production is high, and the oil yield of palm kernel oil is higher. Because the use of machines can control the residual oil rate to a greater extent, the same amount of palm kernel raw materials, if produced by machines, the oil output will be higher.

3. The crude palm kernel oil produced by mechanization is of better quality. Because the crude palm kernel oil has less impurities in the production process, and the plate and frame filter is used for simple filtration at the end, the final palm crude oil obtained is cleaner than that obtained by traditional methods.

4. The use of mechanized extraction of palm kernel oil results in faster oil production, higher daily processing capacity, and more palm kernels can be processed in a shorter period of time.

Through the comparison of the above mechanized and the traditional palm kernel extration method, we can clearly find the advantages of mechanized production, higher production efficiency and higher oil quality. If you are interested in palm kernel oil production, please feel free to inquire. Henan Glory Company has professional engineers and sales teams to help you understand this industry better.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line