Automatic palm kernel oil press production line

Palm kernel oil expeller / Chat on line / Give me a price / Date: March 31, 2021

Automatic palm kernel oil press production line is different from palm fruit oil press production line. As manufacturer of palm kernel oil processing machine, we supply various crude palm kernel oil processing machine and connected equipment. Our palm kernel oil press production line can process palm kernel range from 1 tons per day to 1000 tons per day.

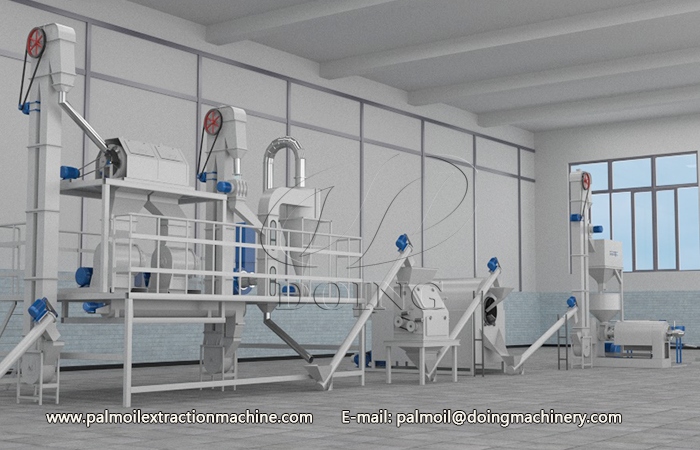

3D animation of small scale palm kernel oil press production line

3D animation of small scale palm kernel oil press production line

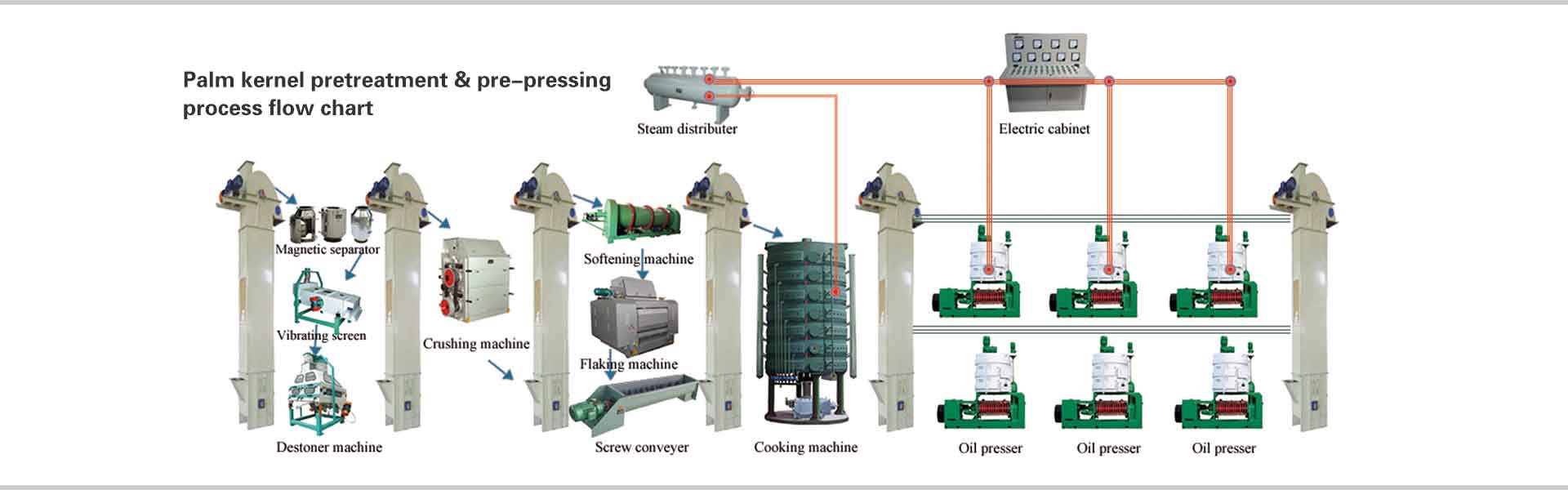

Introduction of our automatic palm kernel oil press production line:

1>. Automatic palm kernel oil press line have seven parts: palm kernel cracking and separating station, cleaning station, crushing station, softening station, flaking station, cooking station, pressing station, filtering station

2>. We use the separated palm kernel, because the palm kernel no shell is more efficiency for whole automatic palm kernel oil press process.

3>. The automatic palm kernel oil press production line can be customized according to the customer's requirements.

4>. The automatic palm kernel oil press production line can adjust the palm kernel into the best condition for oil pressing, which is easy to press oil out.

5>. It also can be used to process other oilseeds, such as soybean, sunflower seeds, rapeseed, peanut and so on.

Large scale palm kernel oil processing plant

Large scale palm kernel oil processing plant

Equipment which directly related to the palm kernel oil press process are divided into eight stations as follows:

Palm kernel cracking and separating station:

Getting pure palm kernel is the first step to process palm kernel. In order to achieve this goal, the palm kernel cracking and separating machine is essential. It consists of palm nuts cracker machine and palm kernel shell separating machine. This palm kernel cracking and separating system can help customers obtain palm kernel quickly and efficiently. Its cracking rate and separation rate are all as high as 95%. It is a good choice for people who want to start small scale palm kernel oil processing business.( Recommended reading: Palm kernel cracking and separating machine)

Small scale palm kenel cracking and separating machine

Small scale palm kenel cracking and separating machine

Palm kernel cleaning station:

It is used for removing the iron impurities, stone, fiber and others. These impurities are bad for automatic palm kernel oil press production line, especial for the palm kernel oil expeller.

Palm kernel crushing station:

Because the palm kernel is hard and big size, it is required to crash to smaller and even pieces. If once crashing can not reach the requirements, the second crashing is required.

Palm kernel crushig machine in Doing Factory

Palm kernel crushig machine in Doing Factory

Palm kernel softening station:

Softening mainly used to adjust the moisture and temperature of oil seeds, softening can increase plasticity of oil seeds. For palm kernel, softening is an essential process for better flaking effect.

Palm kernel flaking station:

Flaking creates beneficial condition for palm kernel cooking.

Palm kernel cooking station:

Cooking is to wet, heat, steam and to cook flakes to change the internal structure of palm kernel flakes, including destroying cells, protein solidification and denaturation, etc. All these changes makes oil easy to isolate and also enhance crude oil quality.

Palm kernel pressing station:

Palm kernel oil expeller machine is the key machine to press palm kernel oil out. Basically we can get most of the palm kernel oil.

Large scale palm kernel oil press machine

Large scale palm kernel oil press machine

Palm kernel filtering station:

After pressing, there are some oil dregs in the crude palm kernel oil, after clarifying, we still need to filter the crude oil to avoid to jam the oil pipes during palm kernel oil refining process.

The above is the simple introduction of automatic palm oil press production line, if you want to get more information about palm kernel oil mill plant projects and want to get running video or images, welcome to contact Henan Glory Company directly.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line