Palm kernel oil production line (From palm kernel to RBDPKO)

Palm kernel oil expeller / Chat on line / Give me a price / Date: July 20, 2022

We are professional palm kernel oil production machine manufacturer, provides complete palm kernel oil production line with input capacity 1-600 tons per day. Total palm kernel oil production process includes three workshops: Palm kernel oil pretreatment and pressing workshop, palm kernel oil solvent extraction workshop and palm kernel oil refining workshop. Each palm kernel oil production workshop has different functions that can help customers achieve different goals. You can customize your palm kernel oil production equipment according to your capacity.

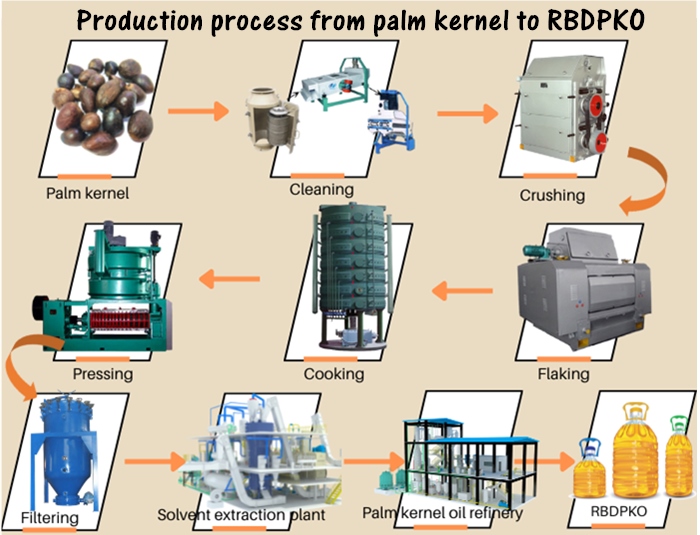

Production process from palm kernel to RBDPKO

Production process from palm kernel to RBDPKO

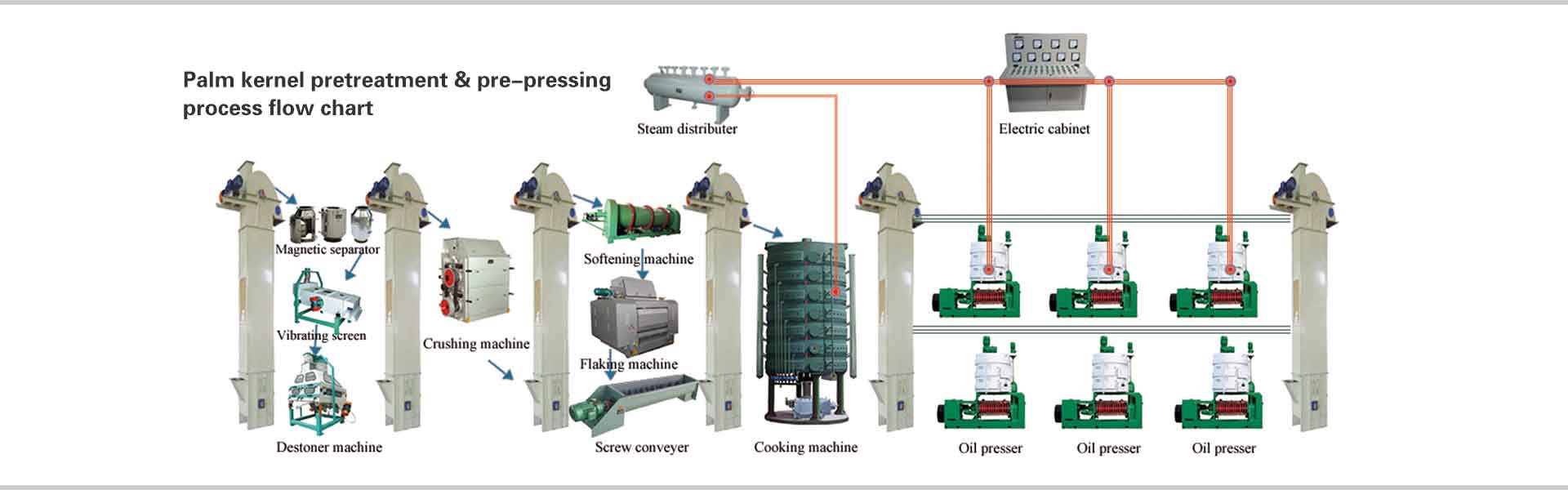

1, Palm kernel oil pretreatment and pressing workshop introduction:

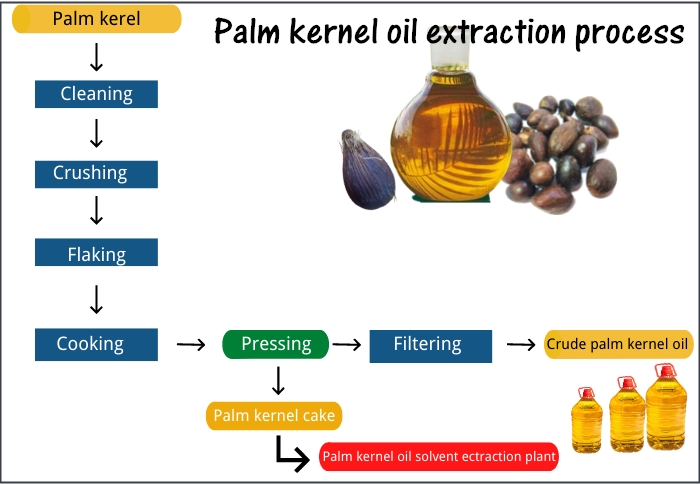

Palm kernel oil pretreatment and pressing machine is also named palm kernel oil press production line, here, we can process palm kernel into CPKO (Crude Palm Kernel Oil ). Palm kernel oil press production line is widely suitable for small medium and large sized palm oil mill plants. The standard palm kernel oil pretreatment and pressing technology mainly includes cleaning, crushing, softening, flaking, cooking, presssing and filtering. Each steps has different functions. As the following picture shows:

Palm kernel oil extraction process

Palm kernel oil extraction process

Main equipment used in palm kernel oil pretreatment and pressing workshop:

Large scale palm kernel oil production machine

Large scale palm kernel oil production machine

2. Palm kernel oil solvent extraction workshop introduction:

Generally speaking, the function of the palm kernel oil solvent extarction workshop is similar to palm kernel oil pretreatment and pressing workshop, they all in order to obtain crude palm kernel oil(CPKO). But palm kernel oil solvent extraction workshop is built on the basis of having palm kernel oil press production line.

Palm kernel oil solvent extraction workshop is using solvent to extract oil from palm kernel cake, finally the oil residue inside meal is less than 1%. And dry meal can be used for animal feed. With the development of science and technology, palm kernel oil solvent extraction technology is becoming more and more important for palm kernel oil production process and more and more investors are willing to invest in palm kernel oil solvent extraction plant to produce more palm kernel oil and obtain high quality palm kernel meal to make more money.

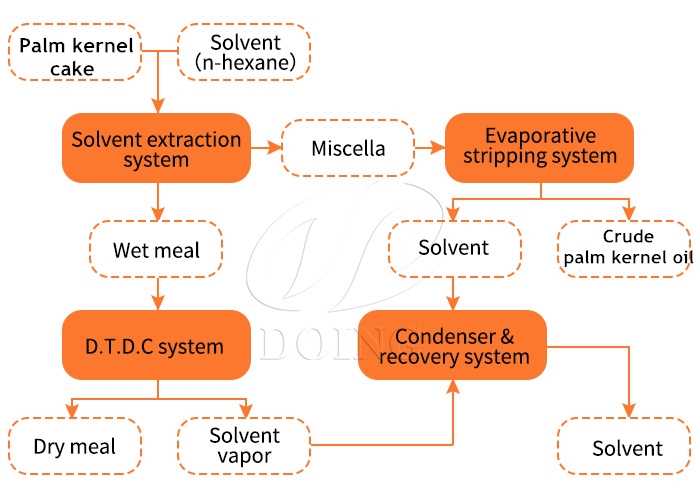

Flow chart of palm kernel oil solvent extarction plant:

Palm kernel oil solvent extraction process

Palm kernel oil solvent extraction process

Main equipment used in palm kernel oil solvent extraction plant:

Palm kernel oil solvent extraction plant photo

Palm kernel oil solvent extraction plant photo

3. Palm kernel oil refinery workshop introduction:

Palm kernel oil refinery workshop belongs to palm oil deep processing workshop, here crude palm kernel oil can be processed into RBDPKO( Refined bleached deodorized Palm Kernel Oil).

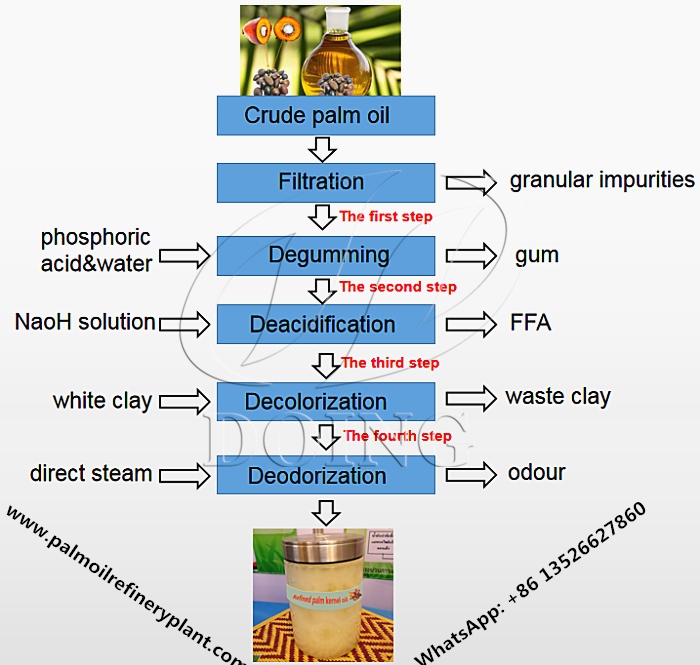

As we all know, no matter after pressing or solvent extraction, the palm kernel oil you get is crude palm kernel oil. Only through refining, including degumming, deacidification, decolorization/bleaching and deodorization process, the gums, acid, pigment and bad smell in the crude palm kernel oil can be removed, and the final oil can be edible oil.

Flow chart of palm kernel oil refinery plant:

Palm kernel oil refining process

Palm kernel oil refining process

According to different processing capacities and clients' requirements for final product oil, palm kernel oil refining machine can be drivied into three types, they are; batch type, semi- continuous and fully continuous.[ Recommended reading: Palm oil refining machine types and their characteristics]

Photos of different types of palm kernel oil refinery plant:

Three different types of palm kernel oil refining machine

Three different types of palm kernel oil refining machine

The three different workshops in the palm kernel oil production line described above are independent workshops. Customers can choose to purchase all of them, or only purchase one or two workshops. If you want to further learning about the situation of each palm kernel oil production workshop, welcome to contact us.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line