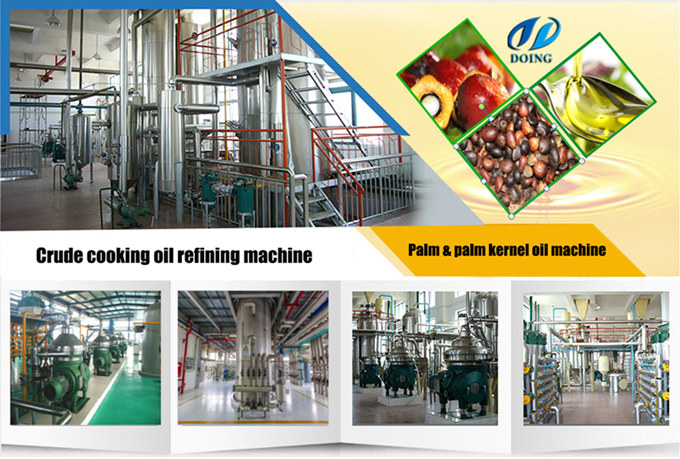

Medium sized palm kernel oil refining plant

Palm kernel oil refinery / Chat on line / Give me a price / Date: August 7, 2018

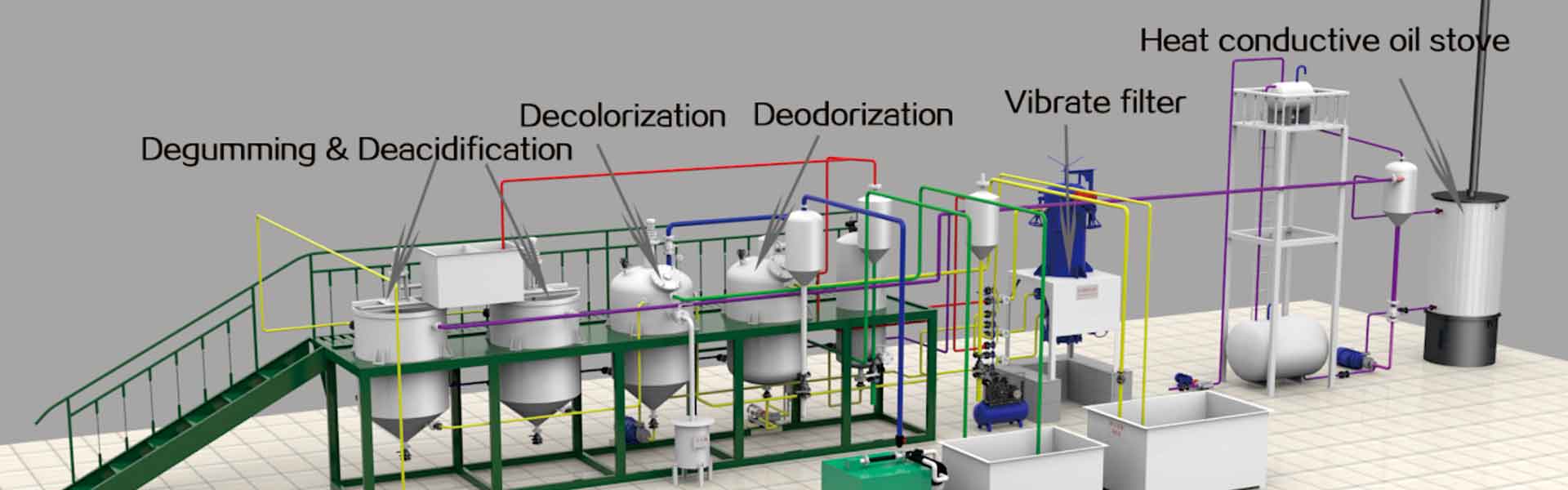

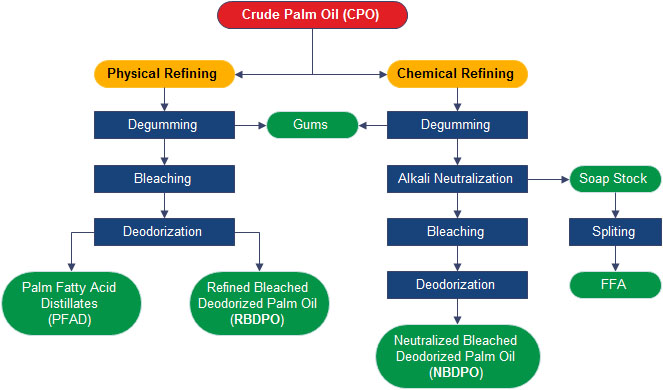

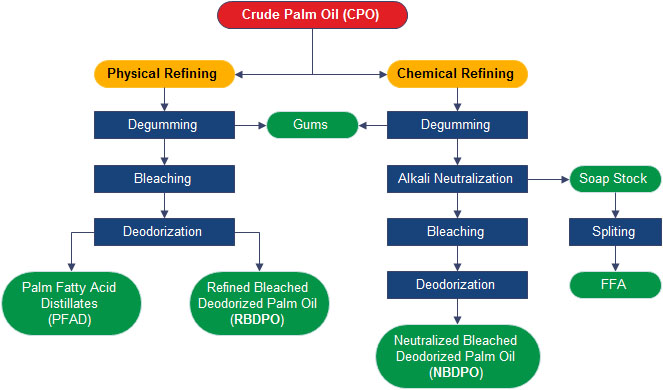

We all know that the crude palm oil without refinery is full of impurities such as gums, pigments, waxes, phosphatides and free fatty acid (FFA), among which some are harmful to our health. So, palm kernel oil refining is essential to remove impurities. Like other oil seeds refining process, medium sized palm kernel oil refining plant has four steps which are degumming, neutralization, decoloring and deodorizing.

Palm kernel oil refining process is the same with palm oil refining process

1. At degumming section, hot water is used here as materials like phospholipids and gums are soluable in oil but not in water. Thus the impurities are separated. Some of them are made into lecithin or added to cakes for flavor. Degumming in palm kernel oil refining plant can improve palm kernel oil edibility and extend storage time.

2. Neutralization is also known as deacidification. Alkali is the main material to neutralize free fatty acids and convert it to soaps which are removed away under centrifugal force.

3. At the decoloring stage of palm kernel oil refining plant, bleaching earth or clay is added to the crude palm kernel oil and heated. The oil is mixed with bleaching earth and keep the mixing and reaction continuously. After decoloring, the bleached oil should be filtered to remove residues created in this step.

4. Palm kernel oil deodorization is the last but not least stage in palm kernel oil refining plant. The bleached oil is deaerate and heated and deodorized in high pressure. After going through the heat exchanger, the deodorized oil should be cooled and filtered. The free fatty acid is collected as by-products.

5. Palm kernel oil's wide market share in edible oil industry raises an urgent claim on edible oil processing crafts. Although the pressing techniques are close to be mature, we still should pay attention to the advanced techniques and endeavor to offer people purer palm kernel oil.

Palm kernel oil refining plant

As a professional manufacturer of palm oil machine in China, we can offer top quality palm oil extraction machine, palm oil mill plant, palm kernel oil processing plant , palm kernel oil refinery plant and so on. We can also offer complete palm kernel oil production line for our customers. Our Sales team is ready to give you a best palm kernel oil refining plant solution.

Palm kernel oil refining process is the same with palm oil refining process

1. At degumming section, hot water is used here as materials like phospholipids and gums are soluable in oil but not in water. Thus the impurities are separated. Some of them are made into lecithin or added to cakes for flavor. Degumming in palm kernel oil refining plant can improve palm kernel oil edibility and extend storage time.

2. Neutralization is also known as deacidification. Alkali is the main material to neutralize free fatty acids and convert it to soaps which are removed away under centrifugal force.

3. At the decoloring stage of palm kernel oil refining plant, bleaching earth or clay is added to the crude palm kernel oil and heated. The oil is mixed with bleaching earth and keep the mixing and reaction continuously. After decoloring, the bleached oil should be filtered to remove residues created in this step.

4. Palm kernel oil deodorization is the last but not least stage in palm kernel oil refining plant. The bleached oil is deaerate and heated and deodorized in high pressure. After going through the heat exchanger, the deodorized oil should be cooled and filtered. The free fatty acid is collected as by-products.

5. Palm kernel oil's wide market share in edible oil industry raises an urgent claim on edible oil processing crafts. Although the pressing techniques are close to be mature, we still should pay attention to the advanced techniques and endeavor to offer people purer palm kernel oil.

Palm kernel oil refining plant

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line