Palm kernel oil processing machine

Palm kernel oil expeller / Chat on line / Give me a price / Date: November 23, 2022

The combination of palm kernel oil processing machines can complete the automatic mechanical oil extraction process. The purpose is to process the fibrous palm kernel through a series of pretreatment, then press it, and finally pass through the refining equipment to obtain edible refined palm kernel oil. The following mainly introduces the three kinds of pressing line process, refining production lines and the equipment used in them. Customers can choose palm kernel oil processing machine according to the specific processing capacity and actual needs.

The complete set of palm kernel oil processing machine includes palm kernel oil pretreatment pressing machine and palm kernel oil refining machine.

Palm kernel oil processing process

Palm kernel oil processing process

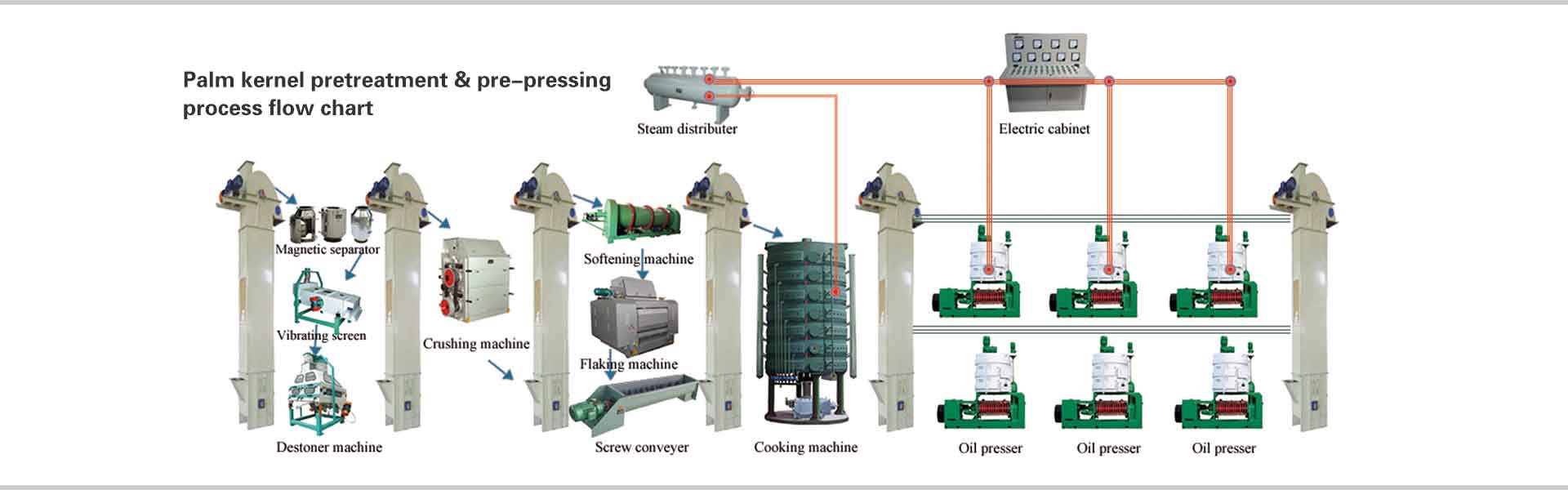

Introduction of palm kernel oil pretreatment press processing machine:

The pretreatment and pressing process of palm kernel oil have a great influence on oil extraction efficiency and production cost. Before entering the palm kernel oil press, the palm kernel undergoes a series of treatments to make its temperature and humidity reach the appropriate level for pressing.

Palm kernel oil pressing machine

Palm kernel oil pressing machine

Fiber separator: Fiber separator is the machine required for the first step of palm kernel oil processing. The purpose is to remove the outer fibers of the palm kernel nut to obtain cleaner palm kernel nut.

Palm kernel shell separation system: First, the palm kernels pass through the grading sieve, and the palm kernel nut are separated according to the size, which is convenient for subsequent cracking. The next step is to enter the cracker to separate the shell of the palm kernel from the kernel nut. Next, it pass through the cyclone separator, where the lighter shells are blown upwards and discharged, while the palm kernels are discharged from below.

Palm kernel crusher: The crusher is used to crush palm kernels, because the kernels are very hard and large, and subsequent cooking will be heated unevenly, which is not conducive to better oil extraction.

Palm kernel cooker: It is used to adjust the moisture and temperature of the brown kernels to the optimum pressing level through steam conditioning. In addition, the cooking process also helps to reduce the viscosity of the oil, break down the cell walls, cause the protein to coagulate, and promote the separation of the oil from the protein substance.

Palm kernel presser: After proper pretreatment, the broken kernels are fed into a palm kernel oil presser, which mainly consists of a rotating worm and a stationary perforated cylinder called a barrel or cage. As the snails rotate, the food is forced through the cage. The volume of the axial displacement of the worm decreases gradually from the feed end to the discharge end, thus compressing the coarse powder when it passes through the barrel. When the palm kernel oil press or oil cake is discharged from the annular orifice, the squeezed oil will flow out of the barrel of the screw oil press. The cold-pressed oil process adds a circulating water system to cool the worm shaft to produce high-quality cold-pressed oil products.

The plate filter: Through the plate filter, filter the fine scum to obtain cleaner oil quality.

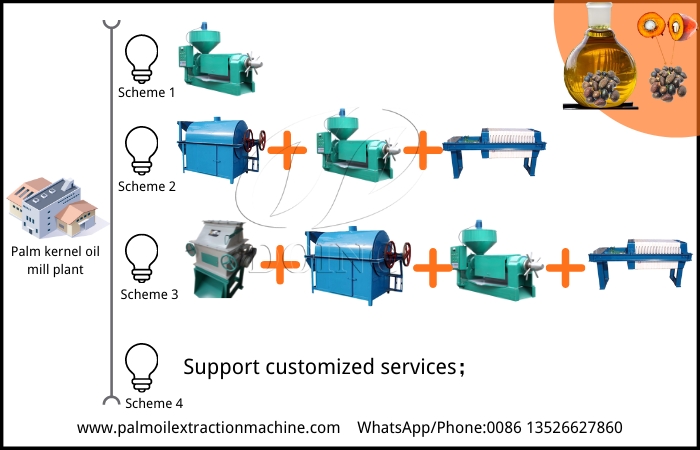

Three kinds of pressing lines process and required palm kernel oil processing machine:

Basic palm kernel oil pressing plant

Basic palm kernel oil pressing plant

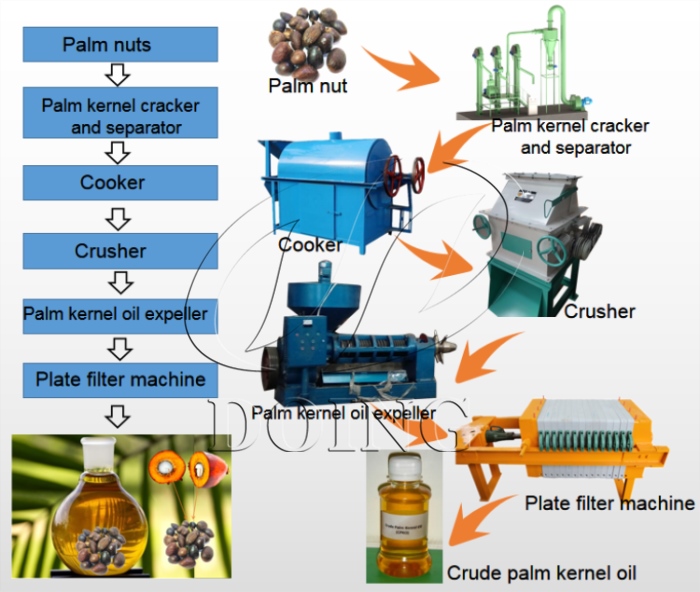

1. The simple palm kernel pressing line is suitable for small capacity and clean palm kernels. Main process includes crusher--cooker--presser--filter--palm kernel crude oil

2. The small and medium-sized palm kernel pressing line is suitable for palm kernel with a daily processing capacity of 5-30 tons. The main process is palm kernel--fiber separation--kernel shell separation system--crusher--cooker--palm kernel presser--filtering--palm kernel crude oil

3. The large palm kernel pressing line is suitable for palm kernel with a daily processing capacity of 30-200 tons. The main process is palm kernel--fiber separation--kernel shell separation system--crusher--cooker--palm kernel pre-pressing--oil cake--sovlent extration system--palm kernel crude oil

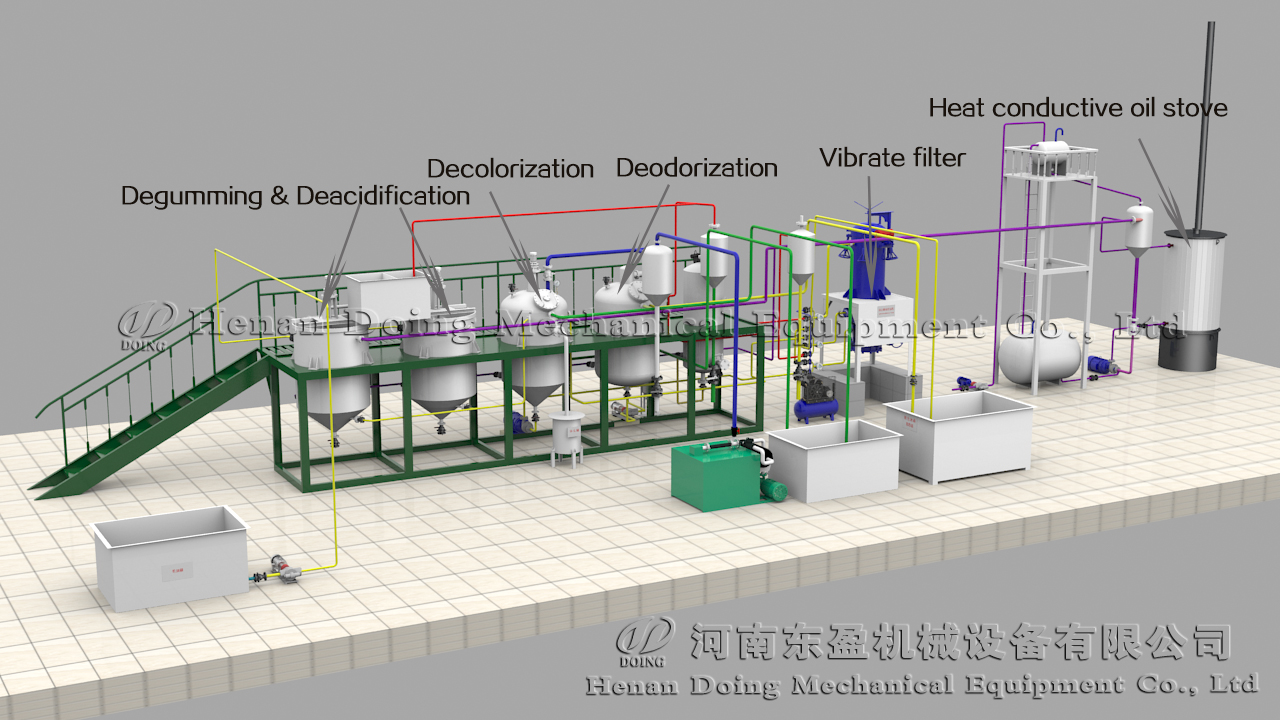

Introduction of palm kernel oil refining processing machine:

Palm kernel oil refining is crucial in palm kernel oil processing. Henan Glory Company' palm kernel oil refining machine can process various crude oils. Our palm kernel oil refining processing includes degumming, deacidification, decolorization and deodorization. It is designed to remove phospholipids, FFA, pigments, gums, waxes, odors and other impurities from crude edible oil to obtain refined palm kernel oil.

Palm kernel oil refining equipment

Palm kernel oil refining equipment

Three types of palm kernel oil refining processing machine to choose from:

1. Batch refining: suitable for small and medium-sized edible oil refineries of 1-20 tons per day, with simple operation, low cost and small investment. Degumming, deacidification, decolorization and deodorization are successively carried out in corresponding towers respectively, and the next step can only be carried out after the previous step is completed.

2. Semi-continuous refining: suitable for 5-30 tons per day, combining the advantages of batch and Full continuous refining plant, it has the characteristics of reliable performance, high degree of mechanization, and excellent process technology. Among them, degumming and decolorization are carried out intermittently, while deacidification and deodorization are carried out simultaneously in a fully continuous deodorization tower.

3. Full continuous refining: suitable for processing capacity of more than 30 tons per day. The full continuous refining is a continuous operation. It is equipped with a centrifuge that can feed and discharge materials at the same time. It works without interruption and has a high degree of production automation. Moreover, the residence time in the tower is just in line with the reaction time, and the oil product is of high quality.

The above is an introduction to the three kinds of palm kernel processing machine. Customers can choose according to their actual needs, or directly consult Henan Glory Company. We have a professional technical and service team to provide customers with high-quality services. If you are interested in palm kernel oil processing machine , please feel free to contact us.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line