Ghana palm oil mill plant feasibility study

Industry news / Chat on line / Give me a price / Date: June 6, 2018

Palm oil mill plant

Palm oil

Opportunity

First, you need to identify if there is a business opportunity in a given area, country or region. A growing demand for palm oil provides an economic opportunity. The abundance of palm trees guarantees a continuous supply of palm fruits. Palm oil processing is labor intensive. The youthful workforce provides cheap labor depending on area of operation. There should also be an opportunity to manufacture further refined products.

Technical Feasibility

Advanced methods of production require new palm oil processing equipment which can be expensive. You need palm fruit reception machine, palm fruit sterilizing machine, palm fruit threshing machine, palm fruit digesting & pressing machine, crude palm oil clarification machine and others. High costs can discourage intending processors from investing and setting up new palm oil mill plants. You can choose to set up small scale palm oil mill plant, medium-sized palm oil mill plant or large scale palm oil mill plant and so on.

Financial Feasibility

Setting up the palm oil processing plant and purchasing equipment requires funds. It also takes into consideration wages and salaries to be paid to employees. Available funds determine the size of the plant and amount of palm oil produced. Economic stability and profitability of palm processing need to be analyzed. There should be demand for palm oil to guarantee profits in the long run. A feasibility study will help determine if the business plan has enough resources to fund the project. Financial implications of oil processing form the basis of the processing business. Palm oil economics uses profitability models like Benefit-Cost Ratio to determine the cost of palm fruits, transportation, hiring/purchasing equipment, availability of labor and market price.

Environmental Feasibility

An environmental impact assessment needs to be carried out as provided by the law. It helps to determine any negative impacts when establishing and operating the plant. Fortunately, all by-products from a palm oil processing plant are recyclable. Empty palm fruit bunches, palm shells can be used as fuel of boiler.

In conclusion, a financially, technically and environmentally feasible project benefits all whenever an opportunity presents itself. The owner of the palm oil processing plant will earn profits. Local people will get jobs, palm oil, and refined products. The products are also recyclable. Carrying out a feasibility study and following laws of the land determines the success of a palm oil processing enterprise.

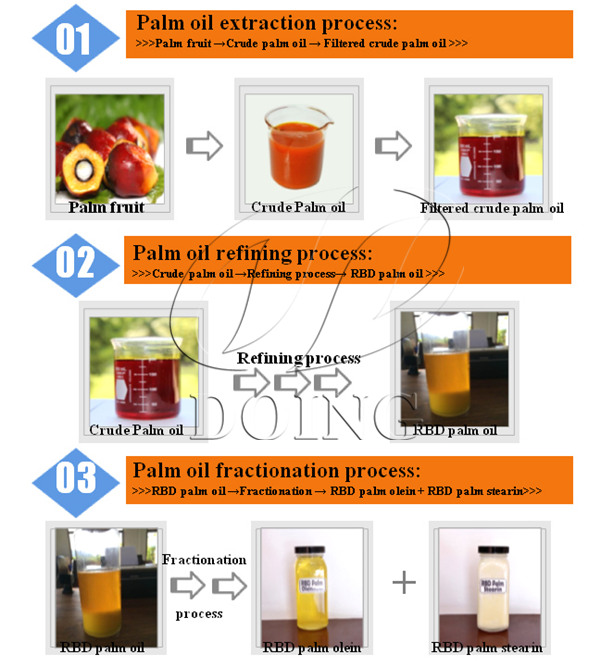

Palm oil production process introduction:

Palm oil production process

Palm oil production process includes 6 parts: Palm bunches receiving, sterilizer, threshing, mashing and pressing, crude oil clarifying and palm kernel recovery.

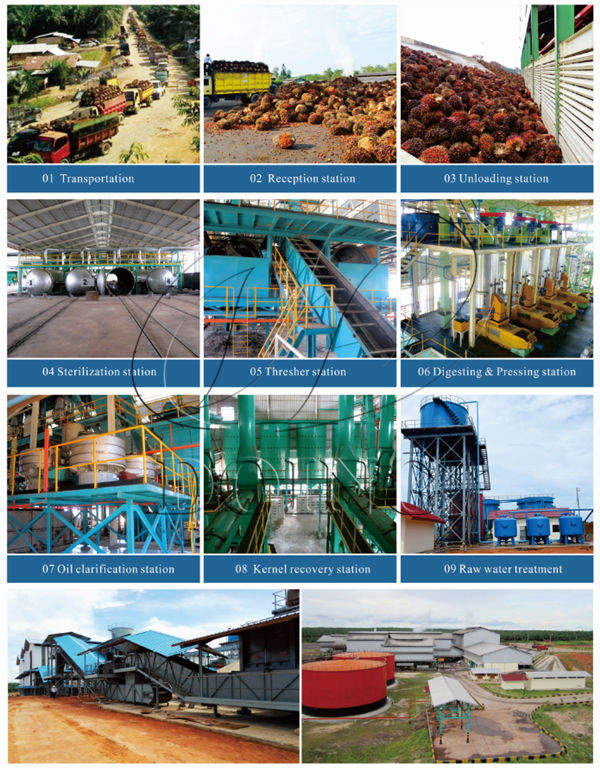

Palm oil production process machinery

The follwing is pictures show of palm oil production machine:

『1』Palm fruit reception station;

『2』Palm fruit sterilzing station;

『3』Palm fruit threshing station;

『4』Palm fruit digesting & pressing station;

『5』Crude palm oil clarification station;

『6』Palm kernel recovery station;

Henan Doing Company is now the largest palm oil processing plant manufacturer and supplier in China. We can not only supply high quality single palm oil expeller, but also offer turnkey projects of palm oil production machine, including palm oil extraction machine, palm oil refinery plant and palm oil fractionation plant. Our palm oil machine business scope as follows:

1-10tph small scale palm fruit processing plant;

15-45tph medium scale palm fruit processing plant;

60-120tph large scale palm fruit processing plant;

1-1000tpd palm kernel oil processing plant;

1-600tph palm oil and palm kernel oil refinery & fractionation plant;

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line