What are the steps in palm oil production?

FAQ / Chat on line / Give me a price / Date: December 19, 2018

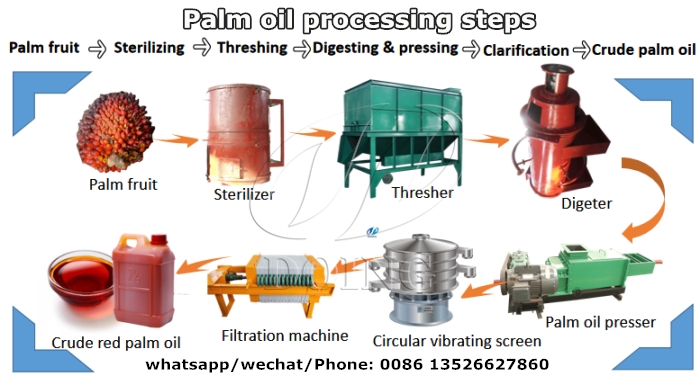

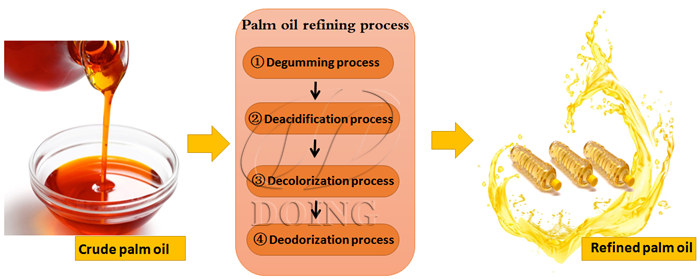

The steps in palm oil production process is divided into sterilization, threshing, digesting, pressing, oil clarification and filtration. If you want to get RBD palm oil, there is also degumming, deacidification, decolorization, deodorization four steps refining process. And if you want to get palm olein and sterine, it will also need palm oil fractionation process.

Palm oil production steps

Palm oil production steps

1. Extraction steps in palm oil production process

The first step is sterilization, through high temperature, to destroy the enzymes in the fruits. At the same time, the high temperature will make the palm fruits soften, it is easy for fruit threshing, and avoiding the damage of palm fruit.

The next step is threshing, the palm fruits go through a thresher, in which each piece of fruit is separated from the rest of the bunch. Large palm oil mill plant place the fruit in rotary drums to complete this process, while small palm oil production facilities perform threshing by hand.

Double screw palm oil press

Double screw palm oil press

After threshing, the next steps in palm oil production is to digesting and pressing. Digesting is for crushing palm fruits, inside the diester, there are baffles and stirring arms, under the driving of the top motor, rimer breaks off the palm fruit and boil the palm fruit. This is followed by pressing, where in heavy metal plates are mechanically pressed into the fruit to squeeze out the oil. Palm oil press machine may use hydraulic or pneumatic power to process large batches at once. The oil is then diluted with water and filtered through a screen to help remove debris and impurities.

At this stage, the palm oil can be sold as a low-quality palm oil or sent on for further processing. For further processing of palm oil, the palm oil refining process and palm oil fractionation process is the necessary palm oil production steps.

Palm oil refining steps

Palm oil refining steps

2. Refining steps in palm oil production process

Step one: Degumming

Add food grade phosphoric acid to the crude palm oil to transform the non hydrated phospholipid into hydrated phospholipid, and add water to make the gum enter the aqueous phase to precipitate and remove.

Step two: Deacidification

Degummed palm oil is added with food grade alkaline for acid-base neutralization reaction and removed by heating and natural sedimentation.

Step three: Decolorization

When the palm oil is heated to a certain temperature, a certain amount of activated clay and activated carbon are added in the neutralized palm oil, the pigment in the palm oil will be physically adsorbed, so as to achieve the purpose of decolorization.

Step four: Deodorization

The deodorized palm oil is heated to high temperature (250-260 ℃) and then enters into the deodorization tank. Under the negative pressure, a small amount of overheated steam is introduced into the palm oil for stripping for a period of time, so as to achieve the purpose of deodorization.

Palm oil refining machine

Palm oil refining machine

3. Fractionation steps in palm oil production process

Palm oil fractionation requires cooling the palm oil to about 24°C and maintaining it for a long time. The components with high melting points will crystallize and precipitate. After secondary filtration, the quality of liquid palm oil can reach the standard of high-end cooking oil.

These are all the steps in palm oil production. Henan Glory Company can provided you with a complete set of palm oil processing equipment. If you have some needs, please contact us.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line