How is palm kernel oil produced?

FAQ / Chat on line / Give me a price / Date: September 28, 2022

Palm kernel oil is usually produced from the kernel of palm fruit by pressing method. Because palm kernel oil contains a lot of low-grade fatty acids, its properties are very different from palm oil, and is very similar to coconut oil, palm kernel oil is widely used in food industry and some industries as a common condiment or raw material.

After a long period of development and research, DOING Company's process of palm kernel oil production line has become very mature. Next, I will introduce the process of palm kernel oil production line, and you can learn about it in details.

As palm kernel is one of the by-products of palm oil production plant, its quantities is not very more, our palm kernel oil production line's processing capacity is 500kg/h to 10t/h, which can be customized according to the requirement of customers.

The process of palm kernel oil production line mainly includes the following steps:

The process of palm kernel oil production line

The process of palm kernel oil production line

1. Fiber separation

There is a layer of fiber on the surface of the palm kernel. The fiber separator is used to remove the fiber on the shell of the palm kernel, which is more conductive to the subsequent shelling and pressing. The remaining fiber can be used as fuel or feed.

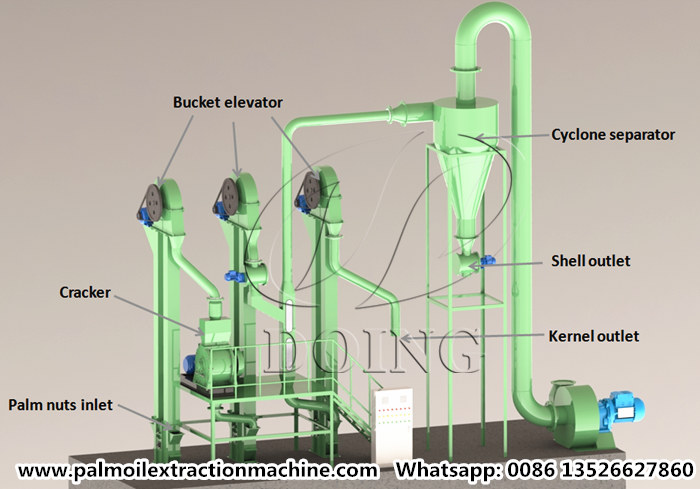

2. Palm kernel shell separation

Palm kernel shell separation is the key step in the whole palm kernel oil production line. It contains magnetic separators, kernel grading sieve, husking machine, and cyclone.

Palm kernel shell separation equipment

Palm kernel shell separation equipment

The function of each equipment:

Magnetic separators - used to remove metal impurities

Kernel grading sieve - divide the palm kernel into uniform sizes.

Husking machine - It can crush the fruit core through impact and friction. The proportion of palm kernel and shell is close, and the crushing efficiency can be up to 95%. According to the weight and force area of the palm kernel and shell, the palm kernel can fall into the hopper of the mobile phone palm kernel, and the separation rate can reach about 95% through the bucket elevator.

Cyclone - Use the wind to make the shell into a whirlwind shape to prevent the shell from floating around when it comes out.

3. Palm kernel crushing

Breaking the palm kernels is more beneficial than steaming and frying, and squeezing out the oil.

4. Steam frying

Adjust moisture content and palm kernel temperature, which is more conducive to oil extraction

5. Palm kernel oil pressing

DOING palm kernel oil presses are mainly 500kg/h, which are made by professional engineers with advanced technology, and are characterized by high oil yield, durability and high efficiency.

6. Filtering

In the filtering stage, it mainly uses the plate and frame filter to remove impurities in the oil and some water.

Each process of palm kernel oil production line is to get more and better palm kernel oil. If you really need to save costs because of budget problems, you can consider simple equipment configuration. For example, if your palm kernel is very clean, you do not need to buy fiber separation. Of course, you can also tell us your budget and specific needs. Our professional engineers and sales teams will provide customized services for you.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line