How to extract castor oil from castor seeds?

FAQ / Chat on line / Give me a price / Date: December 19, 2018

How to extract castor oil from castor seeds?

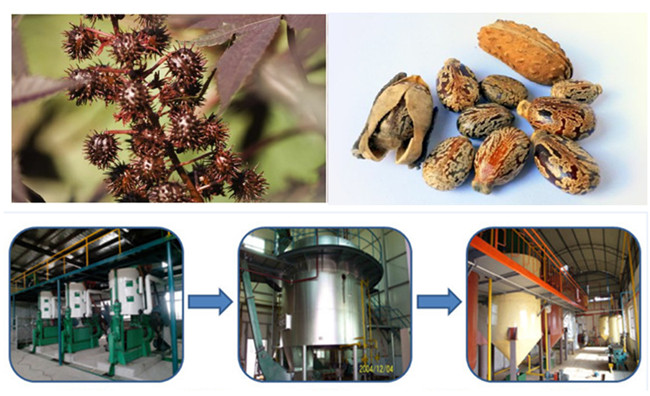

Castor seed is grown commercially on plantations but also harvested from wild plants.The seed must be hulled after harvesting.This can be done laboriously by hand or, more commonly,by machine.Small-scale hand-operated dehullers are available.But how to extract castor oil from castor seeds?The castor oil extraction plant is necessary.The complete set of castor oil production machine is castor oil extraction process mahcine,castor oil filtraction&purification process machine and castor oil refining process machine.

Castor oil production process machinery

Castor oil production process machinery

Castor Oil Extraction Process:

Extraction of oil from castor seeds is done in a manner similar to that for most other oil seeds.The ripe seeds are allowed to dry, when they split open and discharge the seeds.

The seeds are dehulled after harvesting. Dehulling can be done by hand (laborious) or, more commonly, by machine. Small-scale hand-operated dehullers are also available.The dehulled seeds are cleaned, crushed,flaked ,cooked and dried prior to oil extraction workshop. Cooking is done to coagulate protein (necessary to permit efficient extraction), and for efficient pressing.

The first stage of castor oil extraction is pre-pressing, normally using a high pressure continuous screw press – called the castor oil expeller. Extracted oil is filtered, and the material removed from the oil is fed back into the stream along with fresh material. Material finally discharged from the press, called castor cake, contains 8-10% oil. It is crushed into a coarse meal, and subjected to solvent extraction with heptane to extract further oil.

Castor oil processing machine

Castor oil processing machine

Castor Oil Filtration & Purification Process:

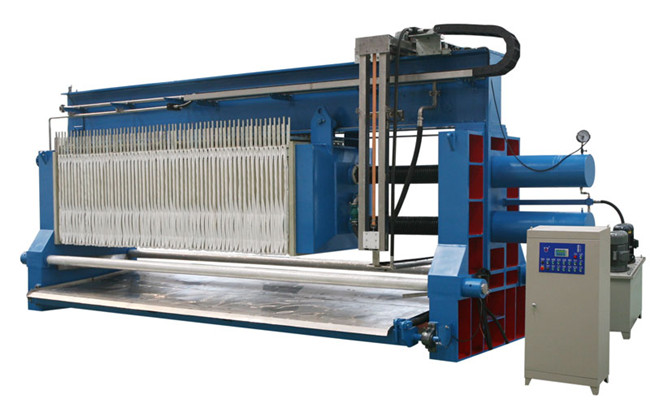

Once the oil has been extracted from the seed, it is necessary to remove impurities present in the oil. The filtration systems are designed to remove particulates, water, dissolved gases, and acids. The equipment that is normally used for filtration is a filter press.

Castor oil filtration machine

Castor oil filtration machine

Castor Oil Refining Process:

The filtered oil (called the crude or unrefined oil) is sent to the castor oil refinery. The steps to refine the crude oil include:

Degumming process of crude castor oil:Done to remove the aqueous phase from the lipids, and to remove phospholipids from the oil.

Neutralization process of crude castor oil:The neutralization step is necessary to remove free fatty acids from the oil.

Bleaching process of crude castor oil:Bleaching results in the removal of coloring materials, phospholipids and oxidation products.

Deodorization process of crude castor oil:Deodorization results in the removal of odour from the oil.

The above is the castor oil extraction process, through castor oil extraction process, castor oil solvent extraction process, we can get crude castor oil, after castor oil filtration and refining process, we can get high quality and good smell castor oil. You can customized your castor oil extraction process according to your requirements.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line