HomeProductPalm oil refineryBatch type palm oil refinery plant and continuous palm oil refinery plant

HomeProductPalm oil refineryBatch type palm oil refinery plant and continuous palm oil refinery plant

Batch type palm oil refinery plant and continuous palm oil refinery plant

Palm oil refinery / Chat on line / Give me a price / Date: May 18, 2022

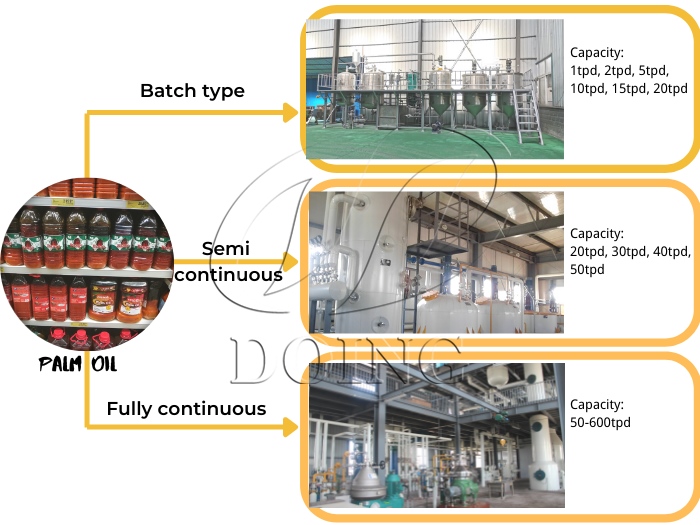

Our company is specialized in palm oil refinery plant. We can provide the palm oil refinery plant from 1 ton to 1000 tons. In general, batch type palm oil refinery plant is with capacity 1-20TPD; The semi-automatic palm oil refinery plant is suggested with capacity from 20-50TPD; And continuous palm oil refinery plant is used for capacity above 50TPD. Of course, this is just an option, not necessary. Our engineer can help you design the whole palm oil refinery plant according to your capacity and requirements.

Different typs of palm oil refinery plant

Different typs of palm oil refinery plant

| 1.Batch type palm oil refinery plant | ||

| Capacity (Ton/Day) | 1-20tpd | |

| Application: |

|

|

| Main equipment: | Refining pot, Decoloring pot, Deodorization tank, Steam generator, Vibrate filter, Electricity distribution control, Air compressor | |

| 2.Semi-continuous palm oil refinery plant | ||

| Capacity (Ton/Day) | 20-50tpd | |

| Application: | Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castor oil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil, etc. | |

| Main equipment: | Refining reactor, Decolorization reactor, Vibrating filter, Deodorizing tower, Deodorized oil pump, Centrifugal water pump, Heat conductive oil furnace | |

| 3. Fully continuous palm oil refinery plant | ||

| Capacity (Ton/Day) | 50-1000tpd | |

| Application: | Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castor oil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil, etc. | |

| Main equipment: | Washing centrifuge, Vacuum dryer, Decolorization tower, Decolorization oil pump, Plate filter, Deodorization tower, Cooling tower, Thermal oil furnace | |

Today we mainly introduce batch type palm oil refinery plant and fully continuous palm oil refinery plant to you:

In batch palm oil refinery process or palm kernel oil refinery process, a measured quantity of oils is processed in sequence of neutralizing, bleaching & deodorizing. For palm oil refinery plants capacity from 1 to 20 tons per day, batch type palm oil refinery process is recommended being low cost and easy to operate.

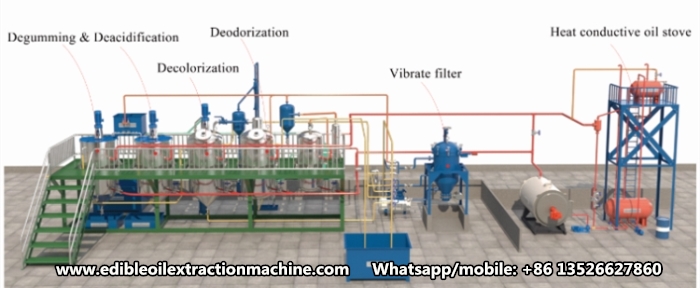

Batch type palm oil refinery plant 3D picture

Batch type palm oil refinery plant 3D picture

Crude palm oil obtained from palm oil expeller or palm oil mill plant contains foreign impurities such as mucilage, gums, coloured & unfiltered matter from the seed. Also Free Fatty Acids (F.F.A.) which tend to deteriorate the oil on storage, thus making it unfit for palm purpose.

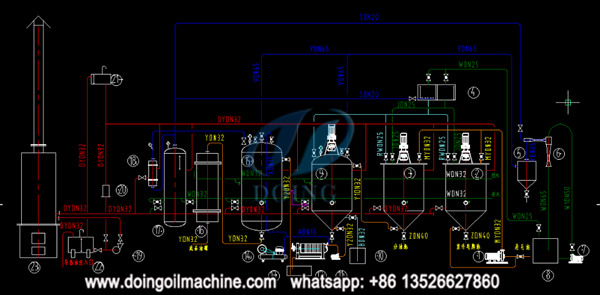

Batch type palm oil refinery process flow chart:

Batch type palm oil refinery process flow chart

Batch type palm oil refinery process flow chart

The batch type palm oil refinery process consists of following section :

Neutralizing / Degumming

Bleaching

Deodorizing

First Stage of palm oil refinery process is to Remove Free Fatty Acids(F.F.A.) wih caustic Soda Treatment called Neutralizing Process Thereafter further processed in the bleaching section under vacuum and treated with bleaching earth and activated carbon for removing colour .Finally it will be Deodorized under high vacuum and high temperature to remove the odour from the oil. The Palm obtained in a batch type palm oil refinery plant is of good quality meeting all requirement

of International Standard.

Continuous palm oil refinery plant introduction:

Continuous palm oil refinery plant

Continuous palm oil refinery plant

Basic process of continuous palm oil refinery plant is same in both batch & continuous palm oil refinery. Only difference is instead of a measured batch, crude palm oil is processed continuously with constant stream of flow. In between required utilities & chemicals are added continuously in measured quantity. Crude palm oil from obtained from palm oil expeller machine, palm oil mill plant contains foreign impurities such as mucilage, gums and unfiltered proteinous matter from the seed. It also contains gums which making it unfit for palm purpose.

Basic stages of the continuous palm oil refinery process are as below:

Neutralizing

Bleaching

Dewaxing & Deodorizing

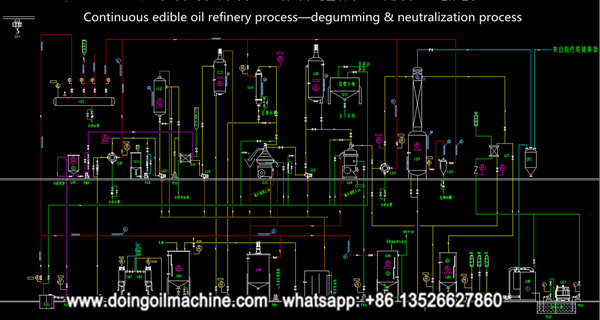

Degumming and neutralization process:

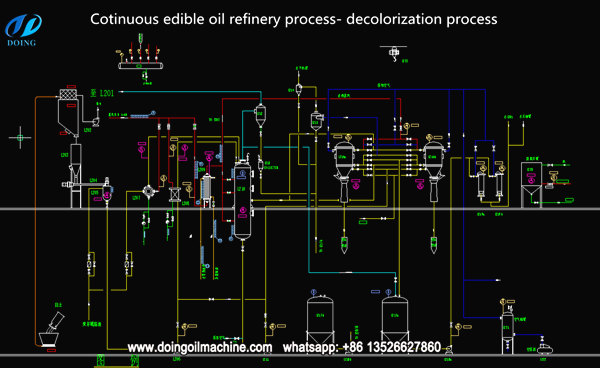

Continuous palm oil refinery process-degumming & neutralization process

Continuous palm oil refinery process-degumming & neutralization process

The crude palm oil is pumped to Neutraliser from palm oil mill plant or storage tank & first it is treated with weak solution of phosphoric acid or other suitable degumming agent for removing gums.

Thereafter oil is further treated with measured quantity of alkali (NaoH) depending upon free fatty acid (F.F.A.) in crude oil. In this process soap will be separated.

Next process is hot water wash to the oil to remove traces of soap particle &free alkali.

The oil obtained will be light in colour, free from soap stock & called as washed Neutralised Oil.

Continuous palm oil refinery process-bleaching process

Continuous palm oil refinery process-bleaching process

In this process excess colour from the oil is removed. The neutralized washed oil is pumped into the Bleacher vessel operating under vacuum.

The oil is first heated to remove excess moisture and thereafter it will be treated with predetermined quantity of bleaching earth & activated carbon.

Thereafter the oil will pass through a filter media (Pressure leaf / Filter press) to separate spent bleach earth and bleached oil.

The oil will pass obtained after bleaching process is light in colour & appearance of oil will be clear golden in colour

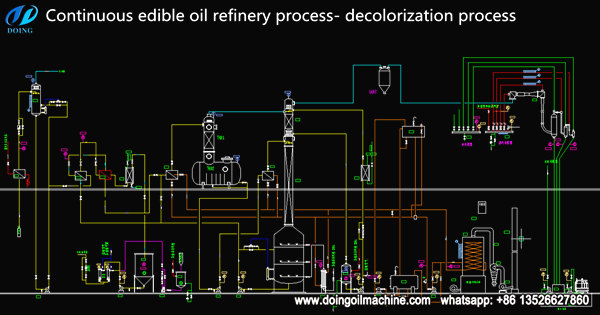

Continuous palm oil refinery process-deodorization process

Continuous palm oil refinery process-deodorization process

This process in continuous palm oil refinery plant removes odour from the oil to improve the quality and self-life of oil.

The bleached oil is charged to deodorizer directly or through heat exchanger and is heated at high temperature and also under high vacuum in deodorizer vessel to obtain odourless clear oil.

Once the decolorization process cycle is complete the oil obtained will be odourless & light in colour.

After cooling it will pass through polishing filter to obtained sparkling light colour & odourless oil for packing, which will be used as palm oil.

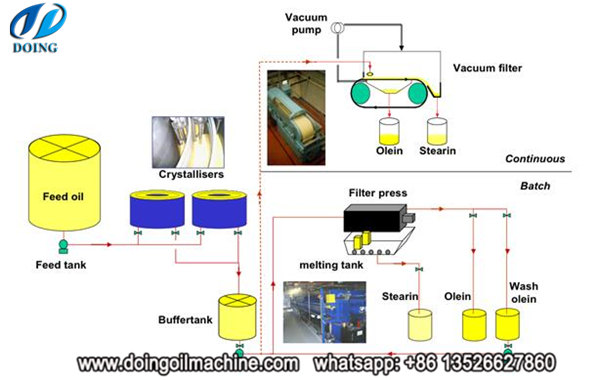

Palm oil fractionation process flow chart

Palm oil fractionation process flow chart

Henan Doing Company know-how provides a Low Operating Cost Palm Oil Fractionation Plant which gives high olein / soft stearin yields at established control i.e. PLC (automation) for efficient working and reliability of the plant.

The separation of Stearin and Olein is continuously done on Rotary Vacuum Drum Filter and its principle is simple, whereas Crystallization process involves a perfect technique to develop and grow the particles size for easy smooth separation of Stearin and Olein

We are experienced in building palm oil refinery plant, palm kernel oil refinery plant and palm oil extraction machine. View our website to find detailed information about palm oil processing plant,palm kernel oil processing plant, other related oil mill machinery. Want to start your oil business and build a customized, palm oil refinery plant with low investment?Henan Doing Company should be your best choice!

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line