Palm oil refinery with capacity of 4 TPD

Palm oil refinery / Chat on line / Give me a price / Date: October 17, 2017

Palm oil refinery with different models

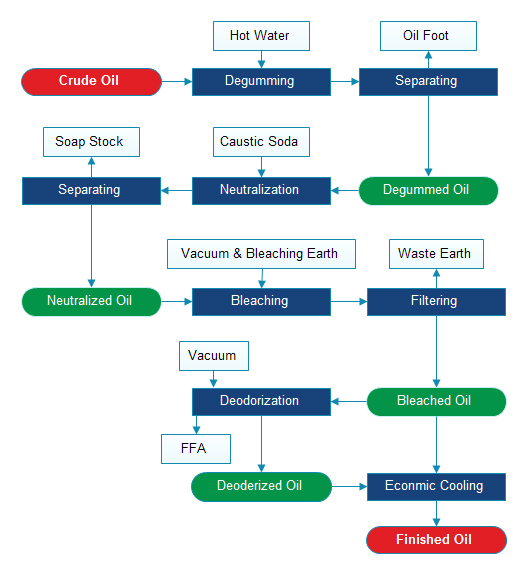

Process flow chart of palm oil refinery:

Palm oil refinery process

1.Degumming.

In this step gums in crude oil are removed by hydration with the help of phosphoric acid. Degumming is the first step for the whole palm oil refinery process.

2. Neutralization.

In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on soap.Neutralization is also called deacidification, it is the important part for palm oil refinery.

3. Bleaching.

During bleaching, unwanted pigments are adsorbed physically and oil will become much clearer. Bleaching is also decolorization in palm oil refinery.

4. Deodorization.

Deodorization is used to remove unacceptable odors by steam distillation, the odoriferous compound are stripped off with the help of live injected steam into heated oil under high vacuum pressure. Deodorization is mainly for making oil color lighter during palm oil refinery process. Which can make oil looks good.

5. Fractionation.

Palm oil wll be two status under a certain tempreature, solid and liquid. We call the solid palm stearin, and liquid is palm olein.

Fractionation is mainly for separating palm olein and palm stearin. In the supermarket, all the oil is palm olein. Palm stearin can be as deep-processing products.

We are experienced in building palm oil refinery plant, palm kernel oil refinery plant and palm oil extraction machine.View our website to find detailed information about palm oil processing plant,palm kernel oil processing plant, other related oil mill machinery. Want to start your oil business and build a customized, palm oil refinery plant with low investment?Henan Doing Company should be your best choice!

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line