Red palm oil manufacturing process machinery

Palm oil press / Chat on line / Give me a price / Date: January 27, 2021

This article is aimed to give a brief description of red palm oil manufacturing process machinery (how palm oil is extracted). Palm oil is an edible oil, derived from the flesh of palm fruit. In the unprocessed form it has a bright red color and is solid.Below you may find steps of palm oil manufacturing process, which palm fruits can be produced into palm oil.

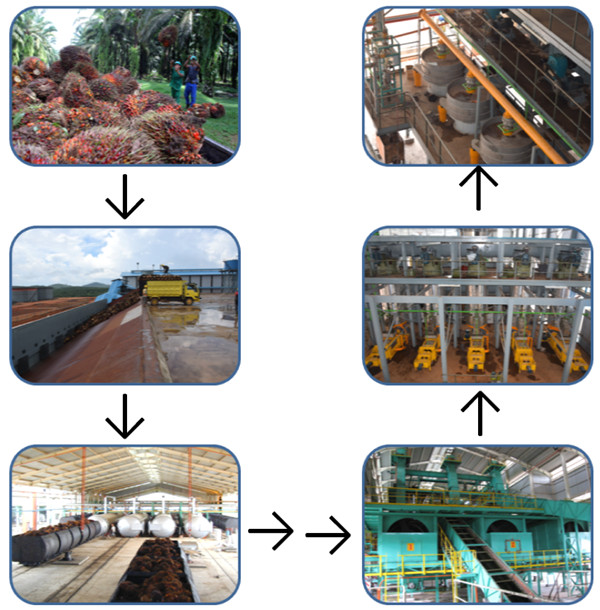

Palm oil manufacturing process machinery

Harvesting of palm oil manufacturing process: The oil palm tree produces fresh palm fruit bunches all year round, but there are periods of high and low productivity. The majority of the oil is formed in the last two weeks of this process and a correct judgment of the ripeness is essential to assure a good production. The palm fruit bunch is removed from the plant by hand with the aid of harvesting tools (sacho and scythe).

The main extraction steps of palm oil manufactuering process are:

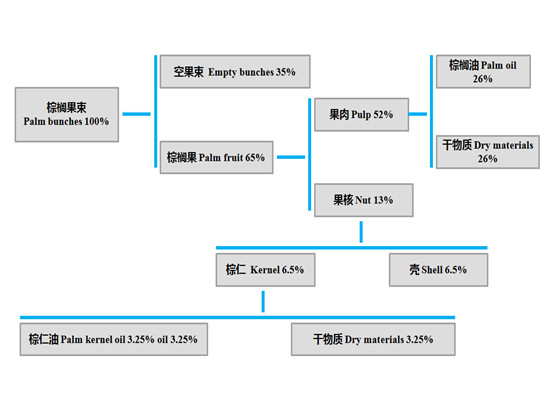

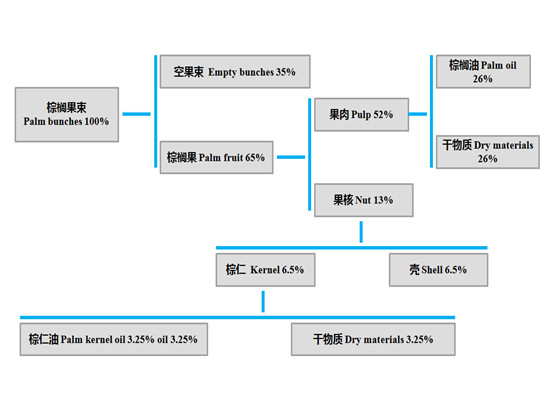

Each section oil content of palm oil

Oil Extraction Losses: Empty bunches and solids from clarification are used as organic fertilizers on certified organic plantation. Fibers still have around 7% oil and shells are used in the boilers as fuel. As a result, all extraction mills are able to generate their own electricity by steam turbines.

We can provide the complete set of palm oil manufacturing process machinery for small scale to large scale palm oil production machine. If you want to build up your own palm oil mill plant or start your own palm oil processing business, please feel free to contact with us for more detailed information of palm oil manufacturing process machinery. We are pleased to offer you the most professional suggestions and services.

Videos:

Large scale palm oil mill processing machine

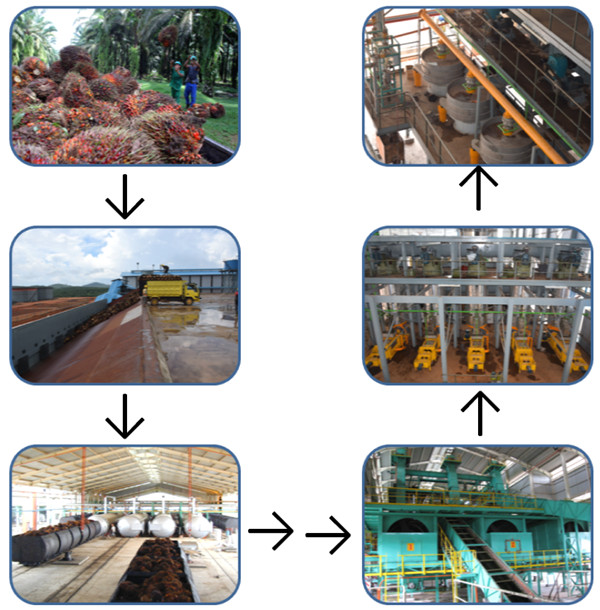

Palm oil manufacturing process machinery

Harvesting of palm oil manufacturing process: The oil palm tree produces fresh palm fruit bunches all year round, but there are periods of high and low productivity. The majority of the oil is formed in the last two weeks of this process and a correct judgment of the ripeness is essential to assure a good production. The palm fruit bunch is removed from the plant by hand with the aid of harvesting tools (sacho and scythe).

The main extraction steps of palm oil manufactuering process are:

|

Sterilization of palm oil manufacturing process: The bunches are cooked with live steam for 90 – 120 minutes. Sterilization objectives are: Lipase enzyme inactivation, making fruits easily release from bunches, making fruits softer, making nut/pulp separation easier, and coagulation of proteins. |

|

Threshing of palm oil manufacturing process: After bunches are cooked they are fed to the thresher of palm oil manufacturing process which is a drum with holes in the side where bunches are centrifuged to separate the fruits. The bunch waste is incinerated and the ash, a rich source of potassium, is used in a compost. |

|

Digestion of palm oil manufacturing process: Digestion is the process of releasing the palm oil in the fruit through the breaking down of oil-bearing cells. Fruits are lifted by a cup elevator to the top of the digester vessel. This vessel contains a live steam heating system and agitator shafts. The main aim during digestion is to break oily cells, in order to make oil extraction easier. This process takes 30 minutes at 90 – 100 ºC. |

|

Pressing of palm oil manufacturing process: Pressing is made just after the material leaves the digestion vessels and it produces a slurry made of approximately 53% oil, 40% water and 7% solids and also a cake that consists of fiber and nuts. Method of pressing could be dry or wet. Dry method is oriented on squeezing the oil out of the mixture of oil, moisture, fibre and nuts by applying mechanical pressure on the digested mash. Wet method uses hot water to leach out the oil. |

|

Clarification, Purification, and Packaging of palm oil manufacturing process: This step consists of separation of oil from impurities (water and fine solids) made in settling tanks and three phase decanters. Recovered oil is then purified in plate centrifuges and dried under vacuum. Finally, the Extra Virgin Palm Oil is filtered to remove any remaining particulate matter and packaged in drums. |

Each section oil content of palm oil

Oil Extraction Losses: Empty bunches and solids from clarification are used as organic fertilizers on certified organic plantation. Fibers still have around 7% oil and shells are used in the boilers as fuel. As a result, all extraction mills are able to generate their own electricity by steam turbines.

We can provide the complete set of palm oil manufacturing process machinery for small scale to large scale palm oil production machine. If you want to build up your own palm oil mill plant or start your own palm oil processing business, please feel free to contact with us for more detailed information of palm oil manufacturing process machinery. We are pleased to offer you the most professional suggestions and services.

Videos:

Large scale palm oil mill processing machine

Large scale palm oil mill processing machine

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line