Palm oil production process

Palm oil press / Chat on line / Give me a price / Date: March 30, 2021

Palm oil production process

Palm oil production process

Palm oil production process is quite different from other oil seeds processing, such as the soybean, peanut etc. Most people understanded palm oil production process refers to how to extract palm oil put from palm fruit. Actually the full set palm oil production process is a comples process which includes many palm oil machins and many palm oil processing process.

The full set of palm oil production process mainly includes: palm oil pressing machine, palm oil refining machine and palm oil fractionation machine. The oil residual in cake after palm oil pressing machine will be about 7%. Palm oil refining machine is mainly used to refine the crude oil comes from palm oil pressing workshop,after palm oil refining process, the oil can meet with first grade standard. Palm oil fractionation machine can obtain palm oil with different melting points.

[Recommend reading: Palm oil extraction technology support ]

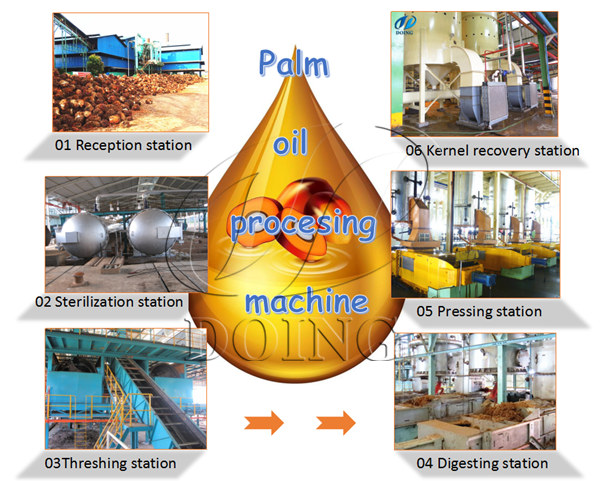

Process flow chart of palm oil production process:

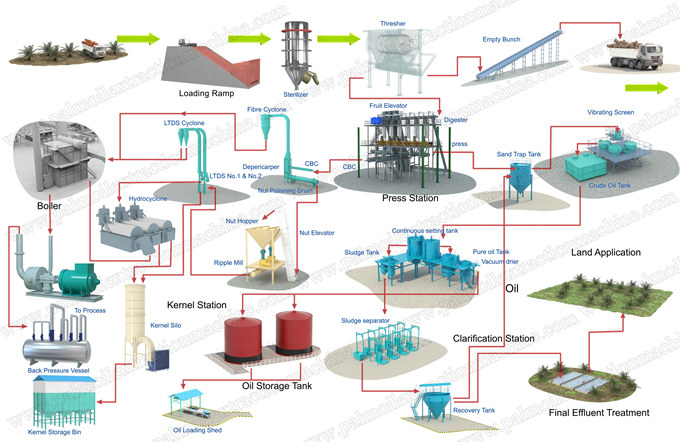

Large capacity palm oil production process flow chart

Large capacity palm oil production process flow chart

Palm oil production process includes 6 parts: Palm bunches receiving, sterilizer, threshing, digesting & pressing, crude oil clarifying and palm kernel recovery.

Palm oil production process

Palm oil production process

1. Reception section:

Collecting the ripe fresh cluster from the orchard and convey by trucks, then pour the fluster into the discharge door after weighed by ground weigher . The discharge door has discharging channels, the upper and lower switches of the iron gate are controlled by pneumatic, Pneumatic control system consists of air compressor and pneumatic control devices. Start the control valve to open the gate of the discharge door, then the palm fruits will fall into the fruit basket car or conveyor.

The ripe palm fruit bunches will be sent to palm oil mill plant to process

The ripe palm fruit bunches will be sent to palm oil mill plant to process

2. Palm fruit sterilizer:

Fresh palm fruit bunch are airtight sterilized in sterilizer, injecting direct steam (the pressure is 300KPa) to heat 60mins. The purpose is to prevent enzymes broken down, avoiding FFA content in oil further increase.

Palm fruit sterilizing machine

Palm fruit sterilizing machine

3.Palm fruit threshing:

The purpose of threshing in palm oil production process is to separate the palm fruit from the FFB. The drum type thresher is the usual machine to separate the fruit. The separated oil palm fruit is sent into the pressing section. Empty fruit bunch be ejected to the yard from the other side of the revolving drum, or shipped out from the plant as palm orchards slipcover to recycling use, or burning in the locale as fertilizer for agricultural land.

Palm fruit threshing machine in palm oil mill plant

Palm fruit threshing machine in palm oil mill plant

4.Palm fruit digesting & pressing section:

There is also the steam heater in digesting section. The purpose of digesting is to separate the pulp and nut and crush the palm pulp. At the same time, the steam is used to cook the palm fruit and broke the cell of pulp. Because of cooking, sterilizing, threshing and digesting in palm oil production process made the pulp soft and damage pulp cell structure, the palm pulp becomes soft and cell is broken. Then it is sent to continuous screw palm oil press machine. After pressing, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).

Palm fruit digesting & pressing machine

Palm fruit digesting & pressing machine

5. Palm oil clarifying section:

Palm oil clarifying section is the main equipment in palm oil production process. Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. Oil by centrifugal separation and through vacuum drying pumped into the storage tank for storing; oil sediment by filtration and dirt oil separation, oil process second settlement, dirt oil mixture process clarification separation, Skim oil then carry out a second settlement, sewage pumps to sewage treatment pond for dealing with.

Palm oil clarifying machine

Palm oil clarifying machine

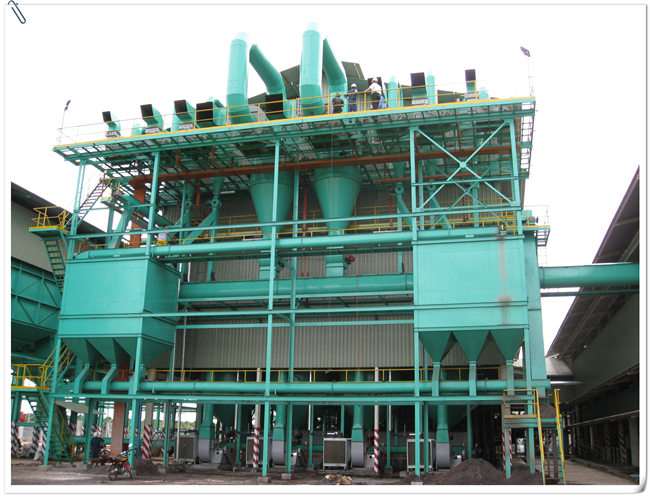

6.Palm kernel recovery section:

Press cake broken by breaking screw conveyor and then transported into the fiber separation air net and fiber polishing roller for fiber separating. The separated fiber material is sent to the boiler room as fuel; the separated palm kernel is transported to kernel warehouse by pneumatic conveying system for temporary storage.

Palm kernel recovery machine

Palm kernel recovery machine

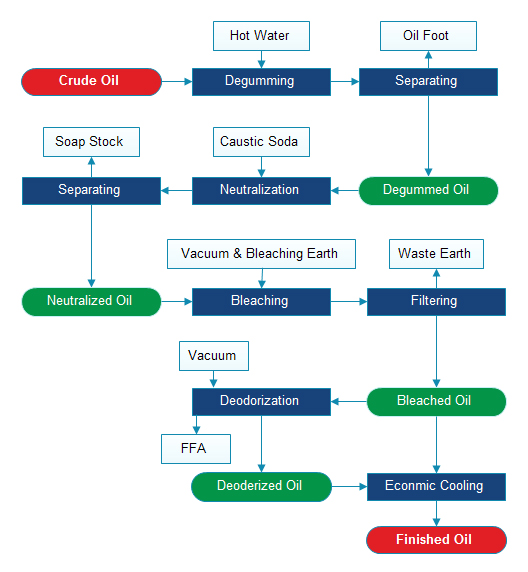

Palm oil refining production process:

Palm oil refining process is another palm oil production process. After palm oil refining process, we can get standard edible palm oil. During palm oil refining process , the most used palm oil processing machine is palm oil refining machine.

Palm oil refining machine is used to get rid of the harmful impurities and needless substances in the crude palm oil,aims at improving the oil storage stability,flavor and color.There are mainly five steps of palm oil refining machine:degumming, deacidification,decolorization, deodorization and fractionation.The palm oil refining machine can be used to pocess other oil seeds of different capacities as well.

Palm oil refining machine

Palm oil refining machine

Process flow chart of palm oil refining machine:

Palm oil refining process flow chart

Palm oil refining process flow chart

Types of palm oil refining machine:

1.Batch type palm oil refining machine,suitable for small capacity like 1-2-3-5-10TPD

2.Semi-continuous palm oil refining machine,suitable for medium capacity like 10-50TPD

3.Full continuous palm oil refining machine,suitable for large capacity above 30TPD ;

Hope this article can help you understand palm oil production process. But if you still have questions, you are welcome to consult us. We Henan Doing Company is pleasure to offer complete set palm oil production solutions for u.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line