FFB palm fruit oil processing plant in China

Palm oil press / Chat on line / Give me a price / Date: October 6, 2017

Henan Doing Company is a professional manufacture of palm fruit oil processing plant. This type of self-sufficient palm fruit oil processing plant adopts mature and reasonable design, assuring high capacity of crude palm oil, low energy consumption, low cost and low environmental pollution.

Palm fruit oil processing plant

Palm fruit oil processing plant introduction:

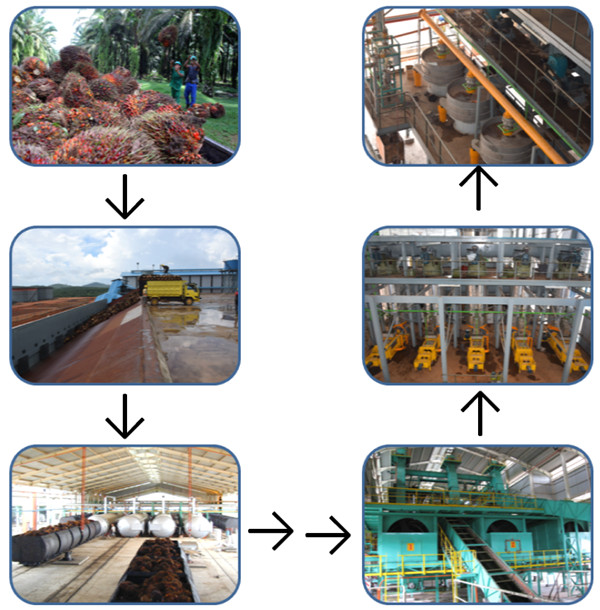

The Fresh Fruit Bunches(FFB) is available after 3 yeas plantation. Palm fruits are sent into crude palm oil processing plant with following production process:

● Weighing. Transport palm fruit to palm oil mill plant after truck weighing so as to make prompt settlement and production cost subsequent.

● Unloading fruit. Fresh Fruit Bunches (FFB) are sent to fermentation tank through transportation machinery after sieving and impurities removing. The time from picking up to fermentation should be less than 24 hours, or the free fatty acid(FFA) will rise, which will not be conductive for further processing and production of palm oil from palm fruit oil processing plant

● Sterilization. After the palm fruit is harvested, it need to be sterilized wthin 48 hours, the purpose of palm fruit sterilization station is to prevent enzymes broken down, avoiding FFA content in oil further increase, at the same time, the temperature will make the fruits soften, palm fruit sterilization station makes it easy for the following process, such as digesting & pressing, it can also reduce the damage of kernel.

● Threshing. In the threshing station of palm fruit oil processing plant, the individual palm fruits will be detached from the bunch by use of FFBs thresher/stripper.Palm fruit threshing station can vibrate palm fruit from palm bunches efficiently. It makes further preparation for next step palm fruit oil rpcessing plant.

● Digesting & pressing.Palm fruit digesting & pressing station is one of station in palm fruit oil processing plant.The purpose of palm fruit digesting station in palm oil processing process is to rupture the oil-bearing cells of fruit and release the palm oil. The palm fruit pressing station in palm oil processing process is to extract palm oil from mashed palm pulp.

Palm fruit digesting & pressing machine

● Fiber separation. The extrued fiber pie enters air separation system after crushed to get separation of fibers and cores.

● Separation. Crusher divided fruit core into palm kernel and shell after separated with fiber. Air separation and washing systems separate palm kernels and shells. Shells enters boiler system as fuel, and palm kernels are storage after drying.

● Oil clarification. The extraction oil contains 45%-55% moisture, sludge and other impurities. Palm oil clarification station is major equipment in palm fruit oil processing plant can extract crude palm oil from sludge. The obtained crude palm oil purity can reach up 90%. Crude palm oil (CPO) contains moisture and impurities after palm oil pressing. CPO begins primary treatment through sand tank and screen, enters vertial clarification tank to make heating and stirring, and finally separate into waste oil and edible vegetable oil. Edible vegetable oil is sent to crude oil storage tank after drying. Waste oil will be retreatment and recovery after desanding and centrifugation.

● Oil transportation. Oil pipeline transportation will be projected on basis of present situation.

● Water treatment. Water source is introduced into palm fruit oil processing plant from river nearby. It will achieve boil feed water standard after primary clarification and filtration, secondary osmosis and reverse osmosis treatment.

● Power system. Steam turb generator power generation is the main driving force. It is also equipped with diesel generator sets.

Features of palm fruit oil processing plant:

● Low environment pollution palm fruit oil processing plant. This palm fruit oil processing plant adopts process of sterilization, threshing, digesting, pressing, clarification, purification, drying, depericarper, crushing and final pressing. This mature design fulfills the lowest fuel consumption, steam driving, and self-sufficient energy supplying.

● Quality and performance reliable and stable palm oil processing plant. The design, manufacturing, and installation are all CE and ISO quality approval. Henan Doing Company Oil Machinry owns rich experience in palm fruit oil processing plant designs more than 30 years and gets national patent certificates of multiple oil milling production lines.

Palm fruit oil processing plant

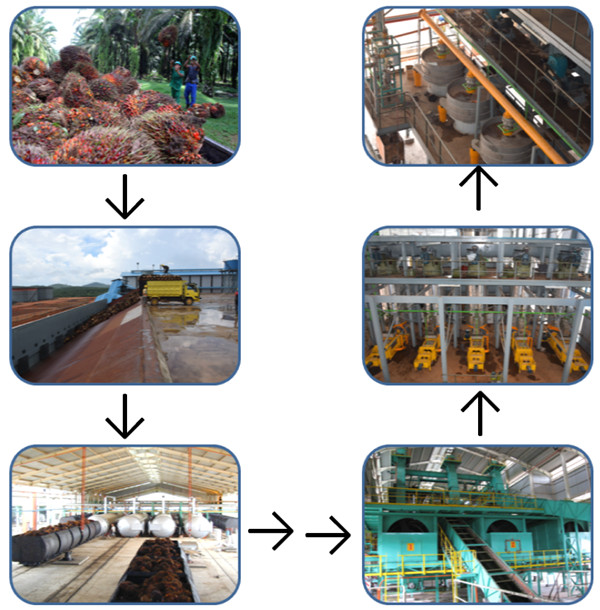

The Fresh Fruit Bunches(FFB) is available after 3 yeas plantation. Palm fruits are sent into crude palm oil processing plant with following production process:

● Weighing. Transport palm fruit to palm oil mill plant after truck weighing so as to make prompt settlement and production cost subsequent.

● Unloading fruit. Fresh Fruit Bunches (FFB) are sent to fermentation tank through transportation machinery after sieving and impurities removing. The time from picking up to fermentation should be less than 24 hours, or the free fatty acid(FFA) will rise, which will not be conductive for further processing and production of palm oil from palm fruit oil processing plant

● Sterilization. After the palm fruit is harvested, it need to be sterilized wthin 48 hours, the purpose of palm fruit sterilization station is to prevent enzymes broken down, avoiding FFA content in oil further increase, at the same time, the temperature will make the fruits soften, palm fruit sterilization station makes it easy for the following process, such as digesting & pressing, it can also reduce the damage of kernel.

● Threshing. In the threshing station of palm fruit oil processing plant, the individual palm fruits will be detached from the bunch by use of FFBs thresher/stripper.Palm fruit threshing station can vibrate palm fruit from palm bunches efficiently. It makes further preparation for next step palm fruit oil rpcessing plant.

● Digesting & pressing.Palm fruit digesting & pressing station is one of station in palm fruit oil processing plant.The purpose of palm fruit digesting station in palm oil processing process is to rupture the oil-bearing cells of fruit and release the palm oil. The palm fruit pressing station in palm oil processing process is to extract palm oil from mashed palm pulp.

Palm fruit digesting & pressing machine

● Separation. Crusher divided fruit core into palm kernel and shell after separated with fiber. Air separation and washing systems separate palm kernels and shells. Shells enters boiler system as fuel, and palm kernels are storage after drying.

● Oil clarification. The extraction oil contains 45%-55% moisture, sludge and other impurities. Palm oil clarification station is major equipment in palm fruit oil processing plant can extract crude palm oil from sludge. The obtained crude palm oil purity can reach up 90%. Crude palm oil (CPO) contains moisture and impurities after palm oil pressing. CPO begins primary treatment through sand tank and screen, enters vertial clarification tank to make heating and stirring, and finally separate into waste oil and edible vegetable oil. Edible vegetable oil is sent to crude oil storage tank after drying. Waste oil will be retreatment and recovery after desanding and centrifugation.

● Oil transportation. Oil pipeline transportation will be projected on basis of present situation.

● Water treatment. Water source is introduced into palm fruit oil processing plant from river nearby. It will achieve boil feed water standard after primary clarification and filtration, secondary osmosis and reverse osmosis treatment.

● Power system. Steam turb generator power generation is the main driving force. It is also equipped with diesel generator sets.

Features of palm fruit oil processing plant:

● Low environment pollution palm fruit oil processing plant. This palm fruit oil processing plant adopts process of sterilization, threshing, digesting, pressing, clarification, purification, drying, depericarper, crushing and final pressing. This mature design fulfills the lowest fuel consumption, steam driving, and self-sufficient energy supplying.

● Quality and performance reliable and stable palm oil processing plant. The design, manufacturing, and installation are all CE and ISO quality approval. Henan Doing Company Oil Machinry owns rich experience in palm fruit oil processing plant designs more than 30 years and gets national patent certificates of multiple oil milling production lines.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line