Palm oil press production machine

Palm oil press / Chat on line / Give me a price / Date: January 27, 2021

Palm oil press production machine

Palm oil press production machine

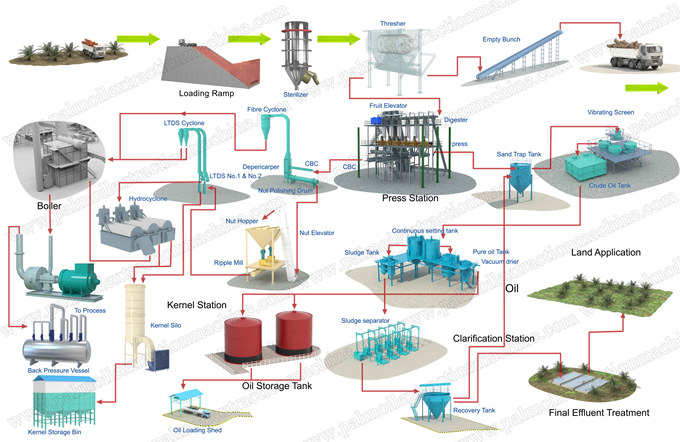

Palm oil press production machine is an important equipment to get crude palm oil.There are mainly six steps of palm oil press production machine:raw material reception,sterilization,threshing,digesting&pressing,oil clarification and kernel recovery.The palm oil press production machine has the advantage of energy-saving and low cost.

Production capacity of palm oil press production machine:

1. 1-2-3-5TPH small palm oil press production machine

1-5tph palm oil press production machine is suitable for home use, family workshop, small scale palm oil production plant. These palm oil press production machine is the best choice for most people start palm oil processing business.

2. 15-30-45-60-80-120TPH palm oil press production machine

15-120tph palm oil press production machine is suitable for large scale palm oil mill. The final quality of palm oil is high ,and the investment cost is also high.

Work flow of palm oil press production machine:

Palm oil press production process flow chart

Palm oil press production process flow chart

1.Raw material reception: as for the first step of palm oil press production machine,collecting the FFB and convey by trucks, then pour the fluster into the discharge door after weighed by ground weigher .Start the control valve to open the gate of the discharge door, then the palm fruits will fall into the fruit basket car or conveyor.

Raw material reception section of palm oil press production machine

Raw material reception section of palm oil press production machine

2.Sterilizing: FFB are airtight sterilized in sterilizer, injecting direct steam (the pressure is 300KPa) to heat 60mins. The purpose is to prevent enzymes breaking down, avoiding FFA in oil further increasing. Meanwhile, the temperature will make the fruits soften, it is easy for threshing and the follow-up palm oil press production machine, it is also reducing the damaged kernel. [Related reading: Palm fruit sterilization machine ]

Sterilizer of palm oil press production machine

Sterilizer of palm oil press production machine

3.Threshing: the purpose of threshing is to separate the palm fruit from the FFB. The drum type thresher is the usual palm oil press production machine to separate the fruit. The separated oil palm fruit is sent into the pressing section. Empty fruit bunch be ejected to the yard as slipcover or burning in the locale as fertilizer. [Related reading: Palm fruit threshing machine ]

Threshing section of palm oil press production machine

Threshing section of palm oil press production machine

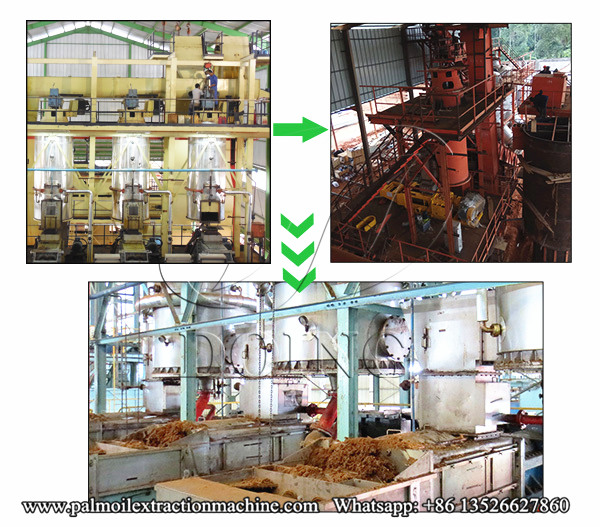

4.Digesting&pressing: the purpose of digester is to separate the pulp and nut and crush the palm pulp. At the same time, the direct steam is used to adjust the water content and temperature in the crasher. After above processing of palm oil press production machine, the palm pulp become soft and cell is broken. Then it is sent to continuous screw palm oil press machine. After pressing by the palm oil press production machine, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).

Digesting&pressing section of palm oil press production machine

Digesting&pressing section of palm oil press production machine

5.Oil clarification: crude palm oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. Oil by centrifugal separation and through vacuum drying pumped into the storage tank for storing; oil sediment by filtration and dirt oil separation, oil process second settlement, dirt oil mixture process clarification separation.

Oil clarification section of palm oil press production machine

Oil clarification section of palm oil press production machine

6.Kernel recovery: first kernel was released by the ripple mill. The broken mixture enters into broken mixture separation system; separation system adopts two stage separation and water separation. After separation, shell is sent to the warehouse for temporary storage, as boiler room fuel when necessary; the moisture content of separation kernel falls to below 7% through the hot air to dry. Dried kernel is sent to kernel storage warehouse for storing.This is the final section of palm oil press production machine.

Kernel recovery of palm oil press production machine

Kernel recovery of palm oil press production machine

After processing by our palm oil press production machine,the crude oil can be sold or deeply processed.we can design and manufacture palm oil press production machine of different capacities according to your requirements.

Our palm oil machine business scope as follows:

Palm fruit /palm kernel pressing line:

1-2-3-5TPH small palm oil processing machine

15-30-45-60-80-120TPH palm oil processing machine;

5-600TPD palm kernel oil processing machine;

Palm oil refining:

1-2-3-5-10TPD batch palm oil refinery machine;

10-15-20-25-30-50TPD semi continuous palm oil refinery machine;

50-80-100-150-300-600TPD full continuous palm oil refinery machine;

Henan Doing Machinery have prolific experience in the manufacture and supply of palm oil press production machines, we have exported our palm oil press production machine to Malaysia, Indonesia, India, Nigeria, Liberia, Kenya,and so on, which has made the company a trusted industrialist of the same in China. With years of development, we have established complete process of designing, manufacturing, installation, commissioning, technical guidance and after-sales service. If you have any interests, please get in touch with us anytime! http://www.palmoilextractionmachine.com

Recommend reading :

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line