5T/H palm oil mill project technical feasibility report

Palm oil press / Chat on line / Give me a price / Date: October 6, 2017

5T/H FFB TO CPO Factory Overview

Product facilities: 6600T/Y palm fruit oil

Receiving section of raw material: 30,000 Ton palm bunch

Leaven-removal section: 35,000 ton palm bunch

Fruit separating section: 30,000 ton palm bunch

Palm fruit oil pressing section: 16,000 ton palm fruit and 6600t oil

Kernel recycling section: 1200t kernel

5T/H Palm Oil mill project economic benefit analysis

(palm oil plant benefit calculation)

Palm oil is now one the world’s largest edible vegetable oil. Palm plantation is low investment and palm oil price is low, thus palm oil has a strong competiveness in the world oil market. Oil palm tree can begin harvest 30 months later, its economic benefit is 25 years. Good palm oil tree (example: TENERA) has heavy palm fruit weight among 10kg to 50kg, and each fruit cluster fruit can reach about 2000 grains. Each fruit contains pulp and nuts. Palm oil content of pulp is 49%, and palm oil content of palm kernel is 50%.

Palm oil mill project report

5 T/H of palm oil mill project economic benefit analysis

According to the current palm oil and palm kernel oil price accounting daily output: (with reference to the market price)

Palm oil (CPO) according to the market price: $800.0/t

Palm kernel oil (CPKO) according to the market price: $2000.0 / t

According to the 300 days one year

Calculated on a year 5 T/H palm oil mill benefits:

22T(CPO)/D×300(D)=6600T/y

6600T/Y×$800.0/t=$5280000.0/Y(Palm oil annual output)

2T(CPKO)/D×300(D)=600.0T/Y (Annual production of palm kernel oil )

600.0T/Y×$2,000.0/t=$1200000.0/Y(Palm kernel oil annual output)

$5280000/Y+$1200000.0/Y=$6480000.0 (5T/H annual input)

The cost of the resources in the process of production because of the different production, consumption level, and here do not calculate.

Palm oil mill products

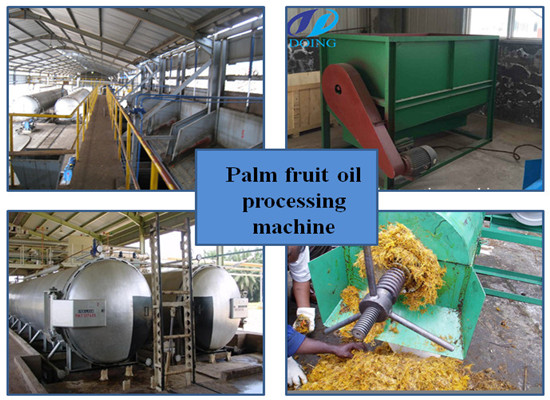

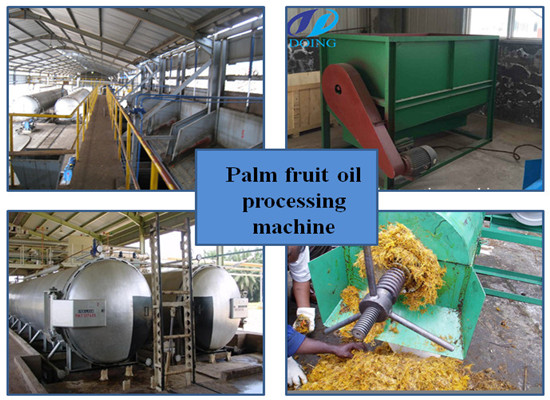

Technological characteristics of 5t/h palm oil mill project :

Crude oil projects includes the processes of receiving section of raw material, leaven-removal, fruit separating, digesting pressing, palm kernel recycling, etc.

Currently crude oil making adopts international advanced and mature technology.

Major equipment of crude oil pressing such as centrifuge and screw oil expeller use imported equipment, assuring high efficiency of separation and product quality.

Continuous production reduces labor intensity and production cost.

Palm crude oil plant scale and raw material:

Palm crude oil plant scale:

960t/d palm cluster; 365 days production full year; 350,000t/y palm fruits.

Raw material:

Main indicators of palm fruit:

Moisture content: ≤25%

Impurity content: ≤1.0%

Oil content: 22%

Crude Oil product scheme:

crude oil moisture content: ≤0.1-0.2%

Impurity content of crude oil:≤0.2%

Palm kernel moisture: ≤ 8%

Husk content of palm kernel: ≤2.0%

Major technical and economic indicators:

Installed capacity: 200.4kW

Power consumption: 19.4kWh/ per ton of material

Steam consumption: 488kg/per ton of material

Water consumption: 320kg/per ton of material

Palm oil processing

Main Section Description:

Loading ramp: As palm fruit unloading, cleaning, storage platforms, all hydraulic segmented discharge.

Threshing: strong vibrations through the fruit from fruit bunch separated.

Pressing Station Digesting: Stir the fruit while cooking again pressing: The pulp stone separation obtained CPO and stone, press machine adopts the double screw helix Continuous discharge and Hydraulic, greatly improving production efficiency.

Sterilization: The use of high temperatures to cook soft fruit bunches and sterilization (145 ℃ ,90-120 minutes), easy to separate fruit bunches fruit, soft fruit, increasing the humidity of the fruit, it is easy to take the oil but also to make verification easier separation of the core-shell, preventing enzymatic decomposition, to avoid elevated levels of free fatty acids.

Clarification Station: The oil and the sludge taken out separately (by 90% pure oil) is taken out of the oil containing 45% -55% of the water, sludge and other things.

Purification: oil purification process - improving pure

Drying: Continuous Vaccum Drier with the oil out of the water, the water can be reduced to 0.1%.

NUT & KERNEL Depericarper (splitter): Through floating dry processing the fruit core and fibers separated. Fiber and other lighter stuff was blown appearance

Crushing (Crusher): stone cracked open grain separation kernel and shell. In Hydrocyclone, the use of kernel and core-shell particle proportion to their separation.

Product facilities: 6600T/Y palm fruit oil

Receiving section of raw material: 30,000 Ton palm bunch

Leaven-removal section: 35,000 ton palm bunch

Fruit separating section: 30,000 ton palm bunch

Palm fruit oil pressing section: 16,000 ton palm fruit and 6600t oil

Kernel recycling section: 1200t kernel

5T/H Palm Oil mill project economic benefit analysis

(palm oil plant benefit calculation)

Palm oil is now one the world’s largest edible vegetable oil. Palm plantation is low investment and palm oil price is low, thus palm oil has a strong competiveness in the world oil market. Oil palm tree can begin harvest 30 months later, its economic benefit is 25 years. Good palm oil tree (example: TENERA) has heavy palm fruit weight among 10kg to 50kg, and each fruit cluster fruit can reach about 2000 grains. Each fruit contains pulp and nuts. Palm oil content of pulp is 49%, and palm oil content of palm kernel is 50%.

Palm oil mill project report

5 T/H of palm oil mill project economic benefit analysis

According to the current palm oil and palm kernel oil price accounting daily output: (with reference to the market price)

Palm oil (CPO) according to the market price: $800.0/t

Palm kernel oil (CPKO) according to the market price: $2000.0 / t

According to the 300 days one year

Calculated on a year 5 T/H palm oil mill benefits:

22T(CPO)/D×300(D)=6600T/y

6600T/Y×$800.0/t=$5280000.0/Y(Palm oil annual output)

2T(CPKO)/D×300(D)=600.0T/Y (Annual production of palm kernel oil )

600.0T/Y×$2,000.0/t=$1200000.0/Y(Palm kernel oil annual output)

$5280000/Y+$1200000.0/Y=$6480000.0 (5T/H annual input)

The cost of the resources in the process of production because of the different production, consumption level, and here do not calculate.

Palm oil mill products

Technological characteristics of 5t/h palm oil mill project :

Crude oil projects includes the processes of receiving section of raw material, leaven-removal, fruit separating, digesting pressing, palm kernel recycling, etc.

Currently crude oil making adopts international advanced and mature technology.

Major equipment of crude oil pressing such as centrifuge and screw oil expeller use imported equipment, assuring high efficiency of separation and product quality.

Continuous production reduces labor intensity and production cost.

Palm crude oil plant scale and raw material:

Palm crude oil plant scale:

960t/d palm cluster; 365 days production full year; 350,000t/y palm fruits.

Raw material:

Main indicators of palm fruit:

Moisture content: ≤25%

Impurity content: ≤1.0%

Oil content: 22%

Crude Oil product scheme:

crude oil moisture content: ≤0.1-0.2%

Impurity content of crude oil:≤0.2%

Palm kernel moisture: ≤ 8%

Husk content of palm kernel: ≤2.0%

Major technical and economic indicators:

Installed capacity: 200.4kW

Power consumption: 19.4kWh/ per ton of material

Steam consumption: 488kg/per ton of material

Water consumption: 320kg/per ton of material

Palm oil processing

Main Section Description:

Loading ramp: As palm fruit unloading, cleaning, storage platforms, all hydraulic segmented discharge.

Threshing: strong vibrations through the fruit from fruit bunch separated.

Pressing Station Digesting: Stir the fruit while cooking again pressing: The pulp stone separation obtained CPO and stone, press machine adopts the double screw helix Continuous discharge and Hydraulic, greatly improving production efficiency.

Sterilization: The use of high temperatures to cook soft fruit bunches and sterilization (145 ℃ ,90-120 minutes), easy to separate fruit bunches fruit, soft fruit, increasing the humidity of the fruit, it is easy to take the oil but also to make verification easier separation of the core-shell, preventing enzymatic decomposition, to avoid elevated levels of free fatty acids.

Clarification Station: The oil and the sludge taken out separately (by 90% pure oil) is taken out of the oil containing 45% -55% of the water, sludge and other things.

Purification: oil purification process - improving pure

Drying: Continuous Vaccum Drier with the oil out of the water, the water can be reduced to 0.1%.

NUT & KERNEL Depericarper (splitter): Through floating dry processing the fruit core and fibers separated. Fiber and other lighter stuff was blown appearance

Crushing (Crusher): stone cracked open grain separation kernel and shell. In Hydrocyclone, the use of kernel and core-shell particle proportion to their separation.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line