Crude palm oil making process

Palm oil press / Chat on line / Give me a price / Date: October 6, 2017

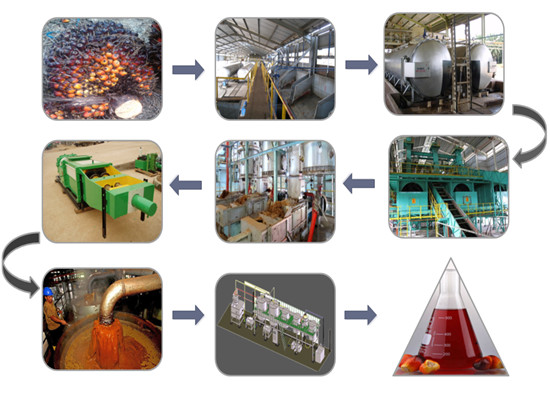

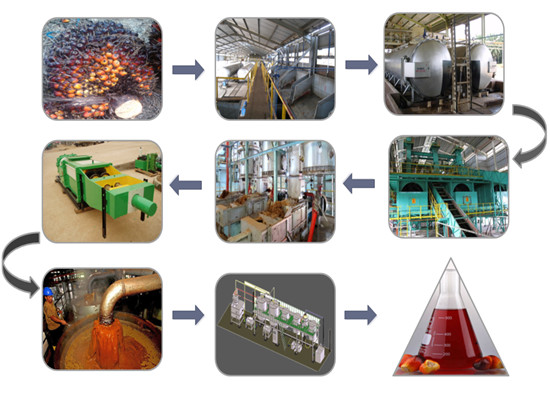

Crude palm oil making process mainly used to prodece palm oil.Crude palm oil making process which directly related to the palm fruit oil process (from fresh fruit to final products) are divided into eight station,they are reception station,sterilization station,threshing station,crashing station,pressing station,oil clarification station,kernel recovery station,and kernel & nut separattion station.

Crude palm oil making process introduction:

Palm oil making process

1.Palm bunch reception station:

Palm bunch reception station is the primary processing of crude palm oil making process. It makes preparation for raw material processing and treatment.Palm bunch reception process is finished at loading ramp. This loading ramp makes palm fruit unloading, cleaning, storage platforms, adopting all hydraulic segmented discharge.

Palm bunch reception station

2.Palm bunch sterilization station

Palm bunch sterilization station utilizes high temperature (145℃, 90-120min) to cook palm bunches. Palm fruit can easily separate from palm bunches and become soft. Owing to increasing humidity of palm fruit, crude palm oil can be easily extracted from fruit. Palm kernel core can much easy separate from kernel shell, preventing enzymatic decomposition, and avoid elevated levels of free fatty acids.

Palm bunch sterilizing machine

3.Palm bunch threshing station

Palm bunch threshing station uses strong vibration to make separation of palm fruit from palm bunches. Raw materials after sterilization are sent to bucket elevator through damp car, and elevated into palm bunch threshing station. Palm fruit separates from bunches, sent to next section elevator through screw conveyor. Empty bunches through conveyor and charger, are transported to certain place for further treatment by car.

Palm fruit threshing machine

4.Palm fruit crashing station

The purpose of palm fruit crashing station is used to separate the pulp and nut and crush the palm pilp.At the same time ,the steam is used to cook the palm fruit and broke the cell of pulp.The best condition of sooking is 90~100℃ for 20 mins.

Palm fruit crashing machine

5.Palm oil pressing station

Because of sterilizing, threshing and crashing made the pulp soft and damage pulp cell structure, the palm pulp becomes soft and cell is broken. Then it is sent to continuous screw press. After pressing, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).The pulp stone separation obtained CPO and stone, press machine adopts the double screw helix continuous discharge and hydraulic, greatly improving production efficiency.

Palm oil press machine

6.Palm oil clarification station

Palm oil clarification station can extract crude palm oil from sludge. The obtained crude palm oil purity can reach up 90%. The extraction oil contains 45%-55% moisture, sludge and other impurities.

Palm oil clarification machine

7.Palm kernel recovery station

Palm kernel recovery station assures high efficiency recovery process of palm kernel after palm oil pressing processing line. Palm kernel recovery station prepares for further step palm kernel oil pressing process after splitter and crushing.

8.Palm kernel & nut separattion station

This is just a brief introduction of palm oil making proces.If you are interested in our palm oil making equipment, please feel free to contact us!!!

Crude palm oil making process introduction:

Palm oil making process

Palm bunch reception station is the primary processing of crude palm oil making process. It makes preparation for raw material processing and treatment.Palm bunch reception process is finished at loading ramp. This loading ramp makes palm fruit unloading, cleaning, storage platforms, adopting all hydraulic segmented discharge.

Palm bunch reception station

Palm bunch sterilization station utilizes high temperature (145℃, 90-120min) to cook palm bunches. Palm fruit can easily separate from palm bunches and become soft. Owing to increasing humidity of palm fruit, crude palm oil can be easily extracted from fruit. Palm kernel core can much easy separate from kernel shell, preventing enzymatic decomposition, and avoid elevated levels of free fatty acids.

Palm bunch sterilizing machine

Palm bunch threshing station uses strong vibration to make separation of palm fruit from palm bunches. Raw materials after sterilization are sent to bucket elevator through damp car, and elevated into palm bunch threshing station. Palm fruit separates from bunches, sent to next section elevator through screw conveyor. Empty bunches through conveyor and charger, are transported to certain place for further treatment by car.

Palm fruit threshing machine

4.Palm fruit crashing station

The purpose of palm fruit crashing station is used to separate the pulp and nut and crush the palm pilp.At the same time ,the steam is used to cook the palm fruit and broke the cell of pulp.The best condition of sooking is 90~100℃ for 20 mins.

Palm fruit crashing machine

Because of sterilizing, threshing and crashing made the pulp soft and damage pulp cell structure, the palm pulp becomes soft and cell is broken. Then it is sent to continuous screw press. After pressing, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).The pulp stone separation obtained CPO and stone, press machine adopts the double screw helix continuous discharge and hydraulic, greatly improving production efficiency.

Palm oil press machine

Palm oil clarification station can extract crude palm oil from sludge. The obtained crude palm oil purity can reach up 90%. The extraction oil contains 45%-55% moisture, sludge and other impurities.

Palm oil clarification machine

Palm kernel recovery station assures high efficiency recovery process of palm kernel after palm oil pressing processing line. Palm kernel recovery station prepares for further step palm kernel oil pressing process after splitter and crushing.

8.Palm kernel & nut separattion station

Fiber polishing machine

|

Palm kernel cracker machine

|

Palm kernel processing machine

Firstly, the wet fiber and wet palm nut enter the cake breaker conveyor to be cracked, and mostly of the fiber should be separated by pneumatic fiber depericarper system. The nut, little fiber and big impurity will be further separated by the polishing drum. The separated nut should be sent to nut hopper through the pneumatic nut transport system, and then adopt the ripple mill to crack the nut, after cracking , most of the shell and kernel will be separated by cracked mixture separating system, and the rest of mixture of palm kernel & shell enter to the special clay bath separating system to separate them, after this processing , we could get pure kernel(The shell content in kernel <6%),which should be conveyed to the kernel silo to dry. After dried moisture as 7%, the kernel will be conveyed to kernel storage bin for storage; Usually the dry kernel’s capacity ratio is 4% . So it should be collected until enough quantity, and then be sent to the palm kernel oil mill; For the separated shell, it should be conveyed to shell temporary bin as the spare boiler fuel.This is just a brief introduction of palm oil making proces.If you are interested in our palm oil making equipment, please feel free to contact us!!!

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line