Palm kernel oil refining process machinery

Palm kernel oil refinery / Chat on line / Give me a price / Date: October 19, 2017

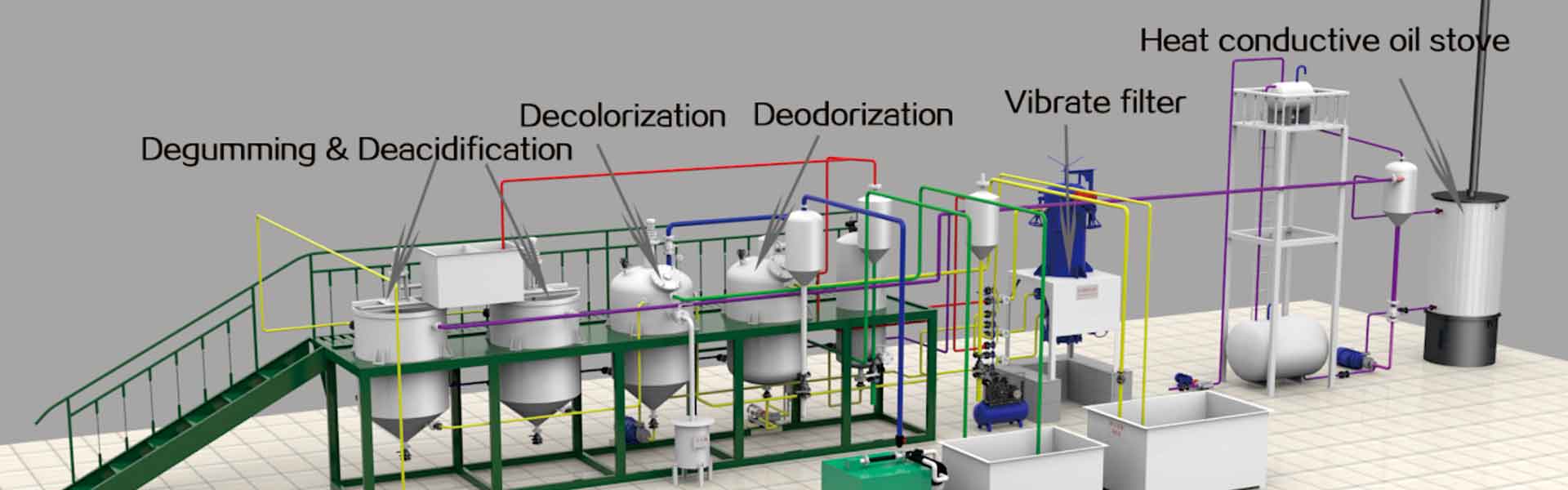

Henan Doing Company palm kernel oil refining process machinery provides professional oil refining process of degumming, dehydration, deacidification, decolorization, bleaching, deodorization, and dewaxing. The complete set of palm kernel oil refining process machinery adopts the most advanced physical refining or chemical refining technology on basis of oil property to get the purest edible oil with the lowest cost consumption.

Palm kernel oil refining machine

General introduction of palm kernel oil refining process machinery:

● Advanced designed palm kernel oil refining process machinery. Henan Doing Company designs advanced and professional oil refinery process to obtain high purity refined oil. It contains hydrated degumming, alkali refining deacidification, negative pressure decoloring process through blenching earth, deodorizing to remove odor components in oil, and dewaxing to remove wax in oil.

The heat conduction oil boiler can supply above 280°C energy to each device, steam generator can supply steam for deodorizing and distillation, vacuum pump can supply vacuum for dehydrate, decolor and deordor. The vibrate filter is used to filter clay and filter out clear oil, and air compressor to blow dry blenched clay and empty the leftover oil in vibrate filter.

● Automatic control system assures high efficiency oil refinery. The application of advanced automatic control system in large palm kernel oil refining process machinery provides the most secured, reliable production in entire workshop and monitors the operation status by controlling the computer terminals.

● Low production cost and high purity refined oil. Henan Doing Company adopts compact palm kernel oil refining process machinery to obtain high purity refined oil with impurity less than 0.2%. The adoption of waste recycle system can protect environment efficiently.

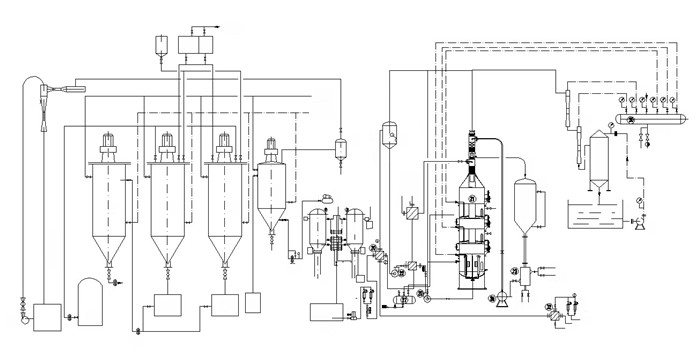

Process flow of palm kernel oil refining machine :

Palm kernel oil refining process flow chart

Palm kernel oil refining machine

General introduction of palm kernel oil refining process machinery:

● Advanced designed palm kernel oil refining process machinery. Henan Doing Company designs advanced and professional oil refinery process to obtain high purity refined oil. It contains hydrated degumming, alkali refining deacidification, negative pressure decoloring process through blenching earth, deodorizing to remove odor components in oil, and dewaxing to remove wax in oil.

The heat conduction oil boiler can supply above 280°C energy to each device, steam generator can supply steam for deodorizing and distillation, vacuum pump can supply vacuum for dehydrate, decolor and deordor. The vibrate filter is used to filter clay and filter out clear oil, and air compressor to blow dry blenched clay and empty the leftover oil in vibrate filter.

● Automatic control system assures high efficiency oil refinery. The application of advanced automatic control system in large palm kernel oil refining process machinery provides the most secured, reliable production in entire workshop and monitors the operation status by controlling the computer terminals.

● Low production cost and high purity refined oil. Henan Doing Company adopts compact palm kernel oil refining process machinery to obtain high purity refined oil with impurity less than 0.2%. The adoption of waste recycle system can protect environment efficiently.

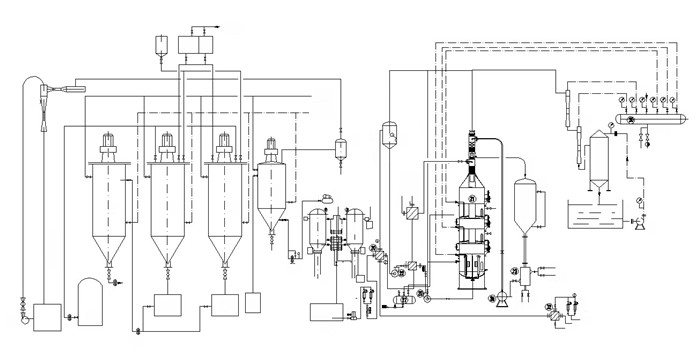

Process flow of palm kernel oil refining machine :

Palm kernel oil refining process flow chart

Technical parameters of palm kernel oil refining process machinery:

| Steam consumption | 700KG/T oil |

| Electric consumption | 28Kwh/T oil |

| Water (soften water) | 150Kg/T oil |

| Phosphoric acid | 2~3 kg/T oil |

| Alkali | acid valuex1-3kg/T oil |

| Circulating water cooling water yield | 150M3/ |

| Bleaching earth consumption | 3-5Kg/T oil |

| Waste bleaching earth oil content | ≤25~35% |

| Refining losses |

acid valuex1.2 (chemical refining) acid valuex 0.6 (physics refining) |

| Bleaching losses | the quantity of bleaching earth×0.25% |

| Deodorization loss consumption | ≤0.5%≤0.5% |

| Refining rate | 1-refining consumption |

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line