Palm kernel oil mill/palm kernel oil refining machine

Palm kernel oil refinery / Chat on line / Give me a price / Date: October 19, 2017

Palm kernel oil mill/palm kernel oil refining machine introduction:

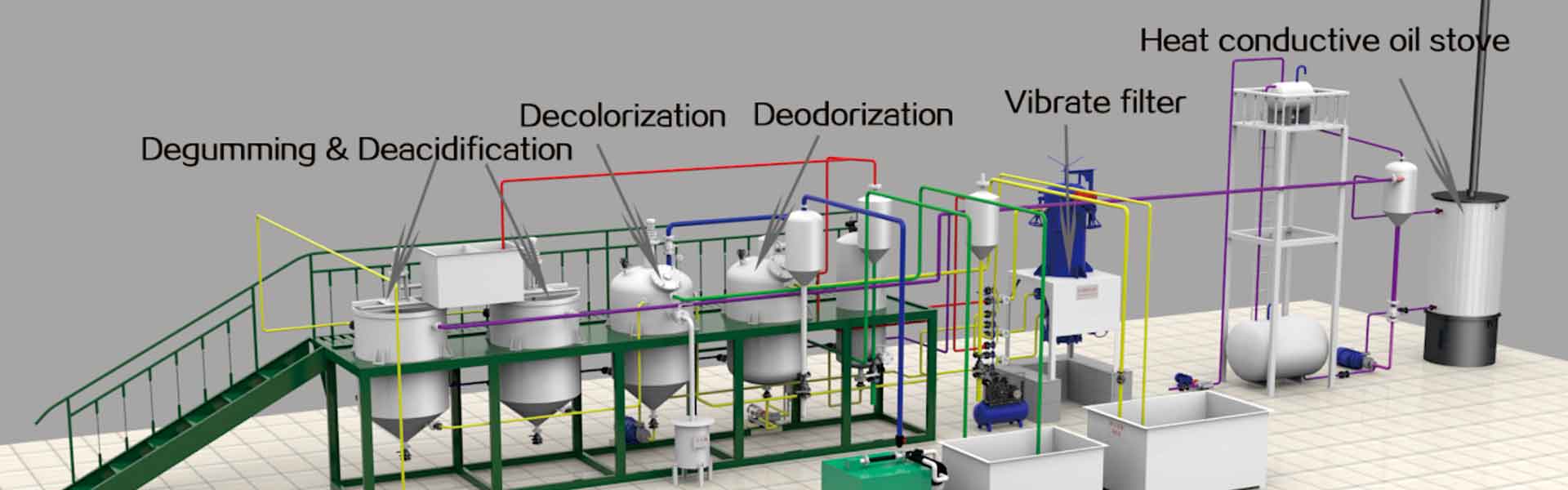

Palm kernel oil refining machine

Edible Palm Kernel Oil Refining and Edible Oil Refining have been the areas of excellence for Henan Doing. We are the basic designers, manufacturers and exporters of complete Edible Palm Kernel Oil Refining machine to refine the crude oil.

Henan Doing manufactures unique edible palm kernel oil refining machine with complete unique construction. Our palm kernel oil refining machine is specifically designed to give the minimum operation costs and maximum output results.The edible palm kernel oil refining machine can refine almost all types of oils. The refined oil quality depends on the type of crude oil and its chemical structure. So far, we have exported our refinery plants to 25 countries of the world.

Process Description of Edible Palm Kernel Oil Refining :

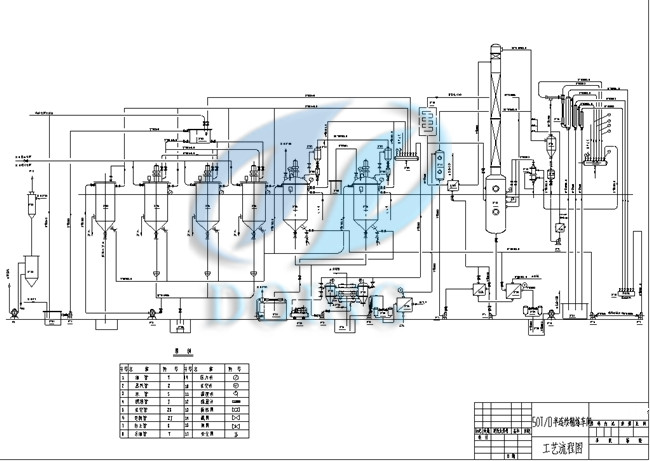

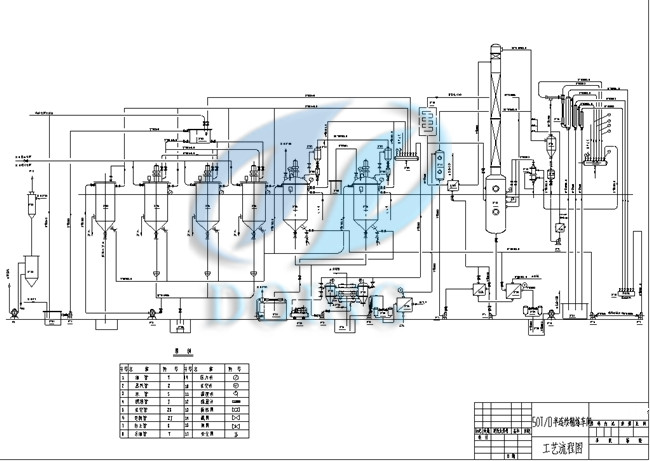

50tpd palm kernel oil refining process

For refining the edible palm kernel oil, there are three basic processes in the palm kernel oil refining machine. First process is neutralizing the oil in the neutralizer to remove the Free Fatty Acids (FFA) by adding caustic soda. Oil is heated up to about 60°C by thermic fluid coils and oil is stirred by stirrer. Then soap stock formed due to chemical reaction is allowed to settle at the bottom of the neutralizer from where it is taken out into soap pan.

Neutralized oil is drawn into the second vessel called bleacher where color of oil is removed by bleaching process with aid of chemicals such as carbon black and bleaching earth. Oil is generally heated up to 110°C by thermic fluid coils. Stirring is also continued. Bleaching process is done under vacuum.

Bleached oil then goes to the filter press where bleaching earth and chemicals are separated and clean bleached oil is then drawn to deodorizer where oil is heated above 110°C through thermic fluid coils and then live steam is given to the oil from the bottom steam nozzles and temperature of oil is raised up to 200 to 220°C through thermic fluid coils. Entire process of palm kernel oil refining machine is done under high vacuum. Thus smell is removed from the oil in the deodorizer. Then it goes to cooler where water circulating coils take away heat and oil is cooled. Again it goes to second filter press where completely refined and transparent color less oil is obtained.

Thermic Fluid Boiler, Vacuum Pump, Barometric Condenser, Catchalls, Steam Generator etc. play their role in the palm kernel oil refining process. So these equipments are part of the refinery and connected with the vessels through pipelines.

Palm kernel oil refining machine

Edible palm kernel oil refining machine is a complex process. To design a reasonable technological process, we also consider the following factors in addition to the above principles:

1.Offer customized palm kernel oil refining machine solution according to different oil varieties (soybean, peanut, cottonseed, rapeseed, vegetable seeds).

2.The application and qualification of refined oil. In addition to various levels of edible oil, there are base oil, drying oil, paint oil, pyrolysis oil, hydrogenated oil, salad oil, cooking oil, vegetable shortening and margarine, etc. Customized palm kernel oil refining process will be offered to meet the quality requirements of different oil.

3.Ensure the process of refining workshop is adapted to the production capacity of your enterprise. Continuous refining plant is suggested for production of large capacity, while batch or semi-continuous types aremore suitable for medium and small oil refining workshops.

4.Others, such as the reliability of the palm kernel oil refining machine and technology,labor productivity, theconsumptionrate of auxiliary materials, steam, water and electricity.

Palm kernel oil refining machine

Henan Doing manufactures unique edible palm kernel oil refining machine with complete unique construction. Our palm kernel oil refining machine is specifically designed to give the minimum operation costs and maximum output results.The edible palm kernel oil refining machine can refine almost all types of oils. The refined oil quality depends on the type of crude oil and its chemical structure. So far, we have exported our refinery plants to 25 countries of the world.

Process Description of Edible Palm Kernel Oil Refining :

50tpd palm kernel oil refining process

Neutralized oil is drawn into the second vessel called bleacher where color of oil is removed by bleaching process with aid of chemicals such as carbon black and bleaching earth. Oil is generally heated up to 110°C by thermic fluid coils. Stirring is also continued. Bleaching process is done under vacuum.

Bleached oil then goes to the filter press where bleaching earth and chemicals are separated and clean bleached oil is then drawn to deodorizer where oil is heated above 110°C through thermic fluid coils and then live steam is given to the oil from the bottom steam nozzles and temperature of oil is raised up to 200 to 220°C through thermic fluid coils. Entire process of palm kernel oil refining machine is done under high vacuum. Thus smell is removed from the oil in the deodorizer. Then it goes to cooler where water circulating coils take away heat and oil is cooled. Again it goes to second filter press where completely refined and transparent color less oil is obtained.

Thermic Fluid Boiler, Vacuum Pump, Barometric Condenser, Catchalls, Steam Generator etc. play their role in the palm kernel oil refining process. So these equipments are part of the refinery and connected with the vessels through pipelines.

Palm kernel oil refining machine

Edible palm kernel oil refining machine is a complex process. To design a reasonable technological process, we also consider the following factors in addition to the above principles:

1.Offer customized palm kernel oil refining machine solution according to different oil varieties (soybean, peanut, cottonseed, rapeseed, vegetable seeds).

2.The application and qualification of refined oil. In addition to various levels of edible oil, there are base oil, drying oil, paint oil, pyrolysis oil, hydrogenated oil, salad oil, cooking oil, vegetable shortening and margarine, etc. Customized palm kernel oil refining process will be offered to meet the quality requirements of different oil.

3.Ensure the process of refining workshop is adapted to the production capacity of your enterprise. Continuous refining plant is suggested for production of large capacity, while batch or semi-continuous types aremore suitable for medium and small oil refining workshops.

4.Others, such as the reliability of the palm kernel oil refining machine and technology,labor productivity, theconsumptionrate of auxiliary materials, steam, water and electricity.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line