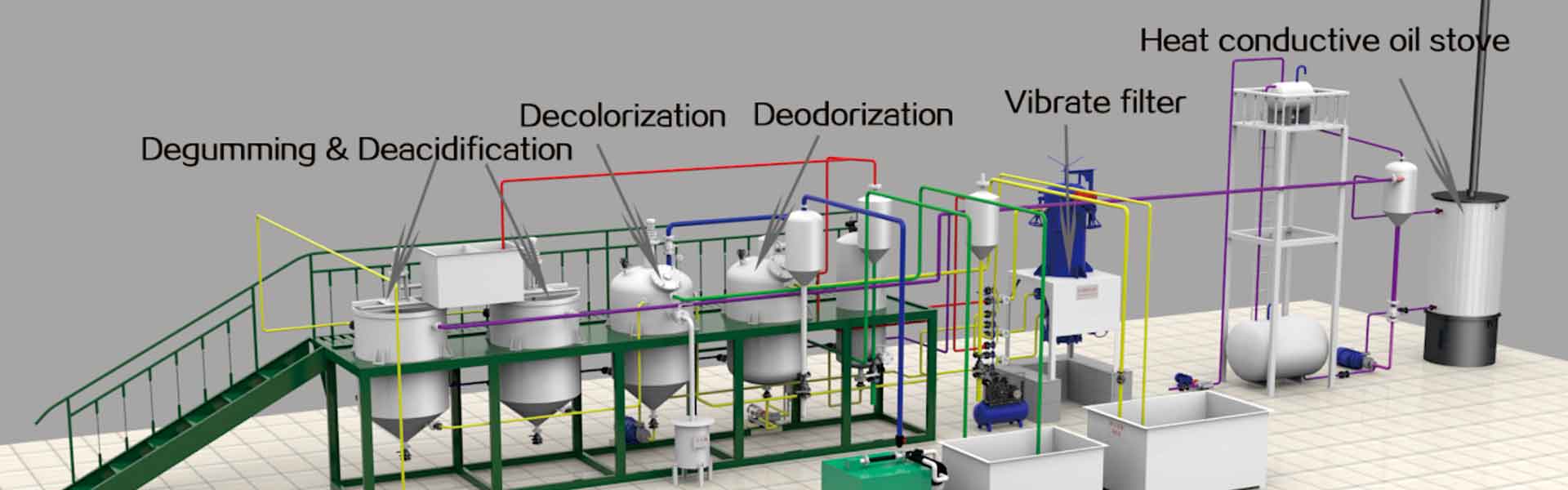

Palm kernel oil refinery equipment

Palm kernel oil refinery / Chat on line / Give me a price / Date: April 9, 2018

Henan Doing Company is a professional manufacturer of palm kernel oil refinery equipment

Refining is a process to remove unwanted and undesirable elements from the crude palm kernel oil. The elements that are removed include the Free Fatty Acids, Phospholipids, Gums,Odour, Color, Waxes etc. Refining makes the vegetable oil clean and pure and improves the overall quality of the oil.

Main process of the Palm kernel oil refinery plant:

1. Crude Palm kernel oil degumming process,

2. Crude Palm kernel oil deacidification/neutralization process

3. Crude Palm kernel oil decoloring/bleaching process

4. Crude Palm kernel oil deodorization/distillation (deodorising unit) process

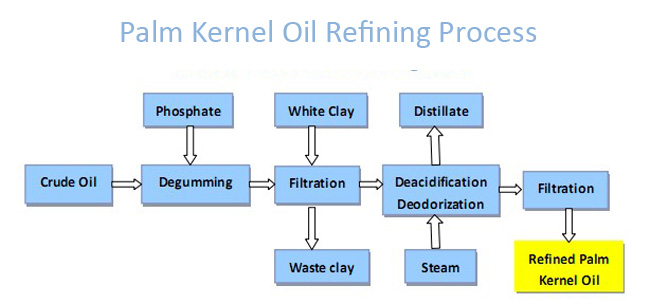

Flow chart of palm kernel oil refinery process:

Palm kernel oil refining process

Introduction of four sections in palm kernel oil refinery equipments :

1.Degumming Section: Some impurity, such as Phospholipid, gum, and protein, can be dissolved into oil when there is no water, but once there is water in oil, these impurity can be dissolved into water. So, in degumming section, we use the hot water to wash crude oil for two-three times to remove these impurity.

2.Neutralizing Section: Crude oil contains much free fatty acid, which is harmful for health. Free fatty acid can have the reaction with caustic soda, during the reaction, it can be saponified and becomes soapstock, then small soapstock pellets will sink and becomes sediment and be pumped out. After neutralizing, most of the free fatty acid will be removed out.

3.Decoloriztion Section: Most of the crude oil has deep color because of the pigments, such as carotene, xanthophyll, etc. We use bleaching earth to remove pigments, because bleaching earth has strong adsorption capacity. Then pump oil into plate filter to remove bleaching earth, then pigment also will be removed out along with bleaching earth, then oil will be clean and transparent.

4.Deodorizing Section: Pure oil has no smell, but different crude oil has their special smell because of some volatile matters, for example the oxide for ketones, aldehydes, hydrocarbons. In deodorizing section, we deliver steam into oil continuously, and make sure steam and oil can fully contacted under high temperature and pressure, then volatile matters can be removed out along with the steam.

Small scale palm kernel oil refinery equipment

Large capacity palm kernel oil refinery equipment

1,Palm kernle oil refinery types:

a. Batch Oil refinery

b. Semi-continuous oil refinery

c. Continuous oil refinery

2,Palm kernel oil rerefining methods:

a.Chemical refining of palm kernel oil refinery;

b.Physical refining of palm kernel oil refinery;

Henan Doing Mechanical Equipment Co., Ltd is a large oil machine company, we have our own factory, and have much professional experience in cooking oil processing equipment manafacture, if you need any palm oil machine, palm oil refining machine , palm kernel oil machine, palm kernel oil refinery plant ,please contact with us, www.palmoilextractionmachine.com.

Prev:Nothing

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line