Palm kernel oil production line:pressing and refining

Palm kernel oil expeller / Chat on line / Give me a price / Date: December 17, 2018

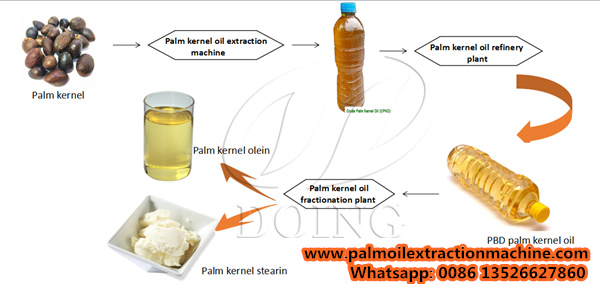

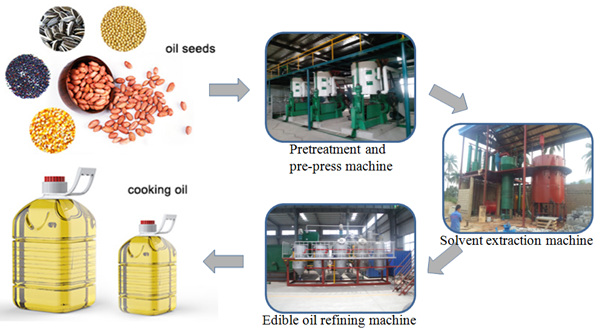

The palm oil production line is the general name for the palm oil production process. The whole set palm oil production line mainly includes palm kernel oil pressing production line and palm kernel oil refining production line. Customers can choose buy palm kernel oil press production line to process palm kernel to obtain crude palm kernel oil for eat or sell. Of course, customers can also choose to buy palm kernel oil refinery plant to make RBD palm kernel oil to achieve greater economic value. If you have enough economic strength, you can choose to buy the full palm kernel oil production line.

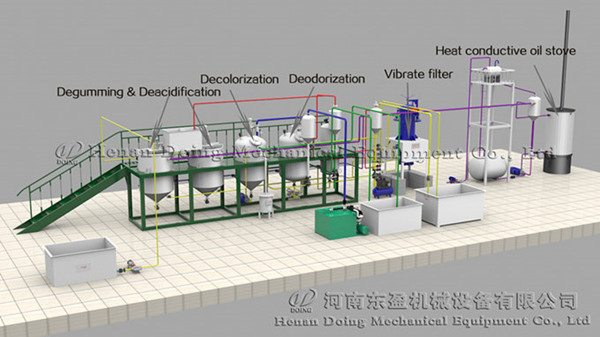

Palm kernel oil produciton line

Palm kernel oil produciton line

Henan Doing Company is professional palm kernel oil production machine manufacturer. We provide complete palm kernel oil processing plants and customized service.We are able to offer a range of professionally designed palm kernel oil pressing machine and palm kernel oil refining machine.

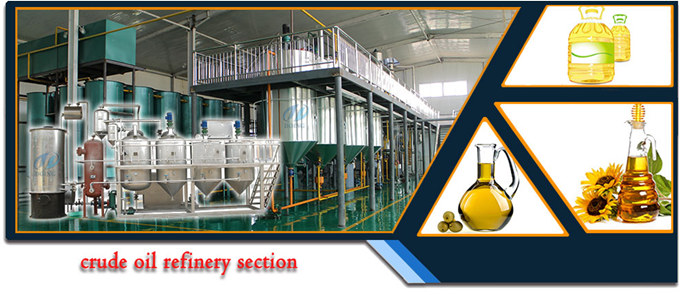

Palm kernel oil production machine

Palm kernel oil production machine

Technical parameters of palm kernel oil production line:

| Type: | palm kernel oil production line |

| Processing material: | palm kernel |

| Capacity: | 1——1000tpd |

| Palm Kernel Oil Pressing Equipment: | palm kernel cracking and separating machine, \crushing machine, softening machine, flaking machine, cooking machine, palm kernel oil expeller and so on. |

| Palm kernel oil refinery plant : | batch type palm kernel oil refinery plant , semi-continuous palm kernel oil refinery plant and continuous palm kernel oil refinery plant. |

| Application: | High efficiency crude palm kernel oil pressing from palm kernel with low oil residual |

Palm kernel oil production line=palm kernel oil pressing production line + palm kernel oil refining production line

Small scale palm kernel oil extraction machine

Small scale palm kernel oil extraction machine

1-10tpd palm kernel oil refinery plant

1-10tpd palm kernel oil refinery plant

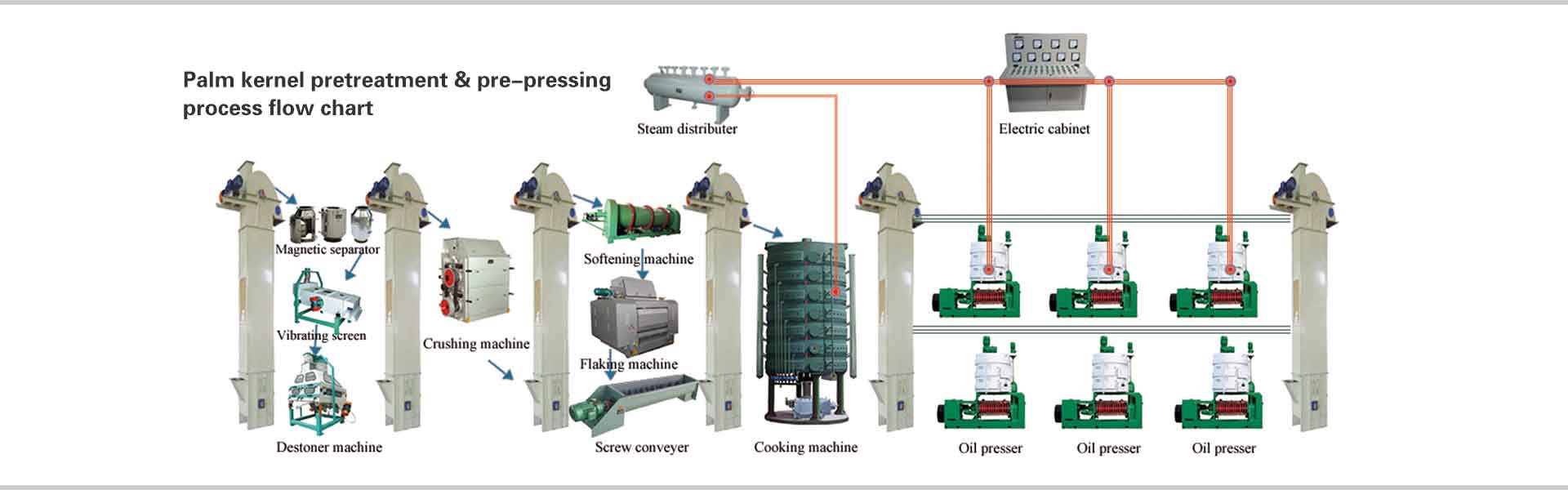

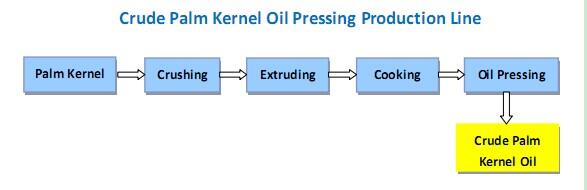

Main process in palm kernel oil pressing production line:

Crude palm kernel oil pressing production line

Crude palm kernel oil pressing production line

Palm kernel oil press production line introduction:

◆Palm kernel Cleaning : It is used for removing the iron impurities, stone, fiber and pthers. These impurities are bad for crude palm kernel oil pressing production line, especial for the palm kernel expeller

◆Palm kernel crushing: because the palm kernel is hard and big size, it is required to crash to smaller and even pieces. If once cruhsing can not reach the requirements, the second crushing is required. Palm kernel crushing machine can make it easy to extract palm kernel oil.

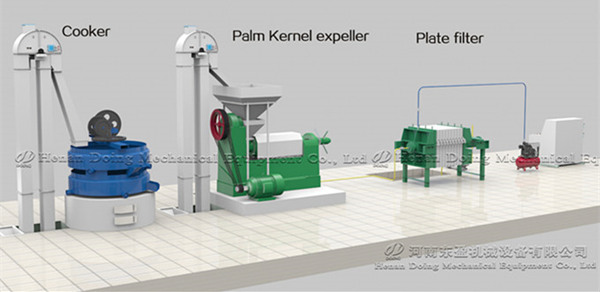

◆ Cooking section: It is used for heating and cooking the crushed materials, to make is suitable for crude palm kernel oil pressing production line, doing like this can help user get the maximum oil and good quality cakes.

◆ Palm kernel oil expeller. Palm kernel oil expeller plays a key role in palm kernel oil production line, no palm kernel oil expeller machine, we can't get crude palm kernel oil and refined palm kernel oil. Palm kernel oil expeller machine can help us to extract out most of palm kernel oil.

◆ Palm kernel Filtering section: after palm kernel oil expeller pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil pipes during palm kernel oil refinery processes.

Palm kernel oil pressing workshop

Palm kernel oil refining production line introduction : Palm kernel oil is non-drying oil with low gum content, which is suitable for physical refinery. In palm kernel oil refinery process, we usually use physical refining methods to refine crude palm oil. The complete set palm kernel oil refining includes the following process: palm kernel oil deacidification process, palm kernel oil decolorization process and palm kernel oil deodorization process.

Palm kernel oil refining machine

Palm kernel oil refining machine

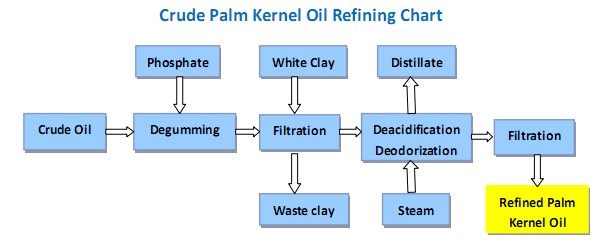

Process Flow chart of palm kernel oil refining machine:

Crude palm kernel oil refining process flow chart

Crude palm kernel oil refining process flow chart

Outstanding features of palm kernel oil refining machine:

◆ No need of degumming. Physical oil refining is applicable because of low gum content inside palm kernel oil.

◆ High vacuum deacidification. Gas supported heat-conducting oil boiler and packed tower make high vacuum deacidification from crude palm kernel oil.

◆ Decolorization. Whit clay makes continuously decolorization of crude palm kernel oil, and enters into filter for filtration.

◆ Fat acid Condensing recovery. Stainless steel recycled water is adopted to make direct condensing recovery of fat acid

Our company provide various types of palm kernel oil production machine to customize different oil processing capacity. We ensure the best quality and best price. If there are any needs, please email us!

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line