Palm kernel expeller press machine

Palm kernel oil expeller / Chat on line / Give me a price / Date: April 19, 2019

Palm kernel expeller press machine is designed using the most advanced technology by experienced professionals. These palm kernel expeller press machine make it easy to extract palm kernel oil. We Henan Doing Company have different types palm kernel expeller press machine for people to choose.

Palm kernel oil processing machine

Palm kernel oil processing machine

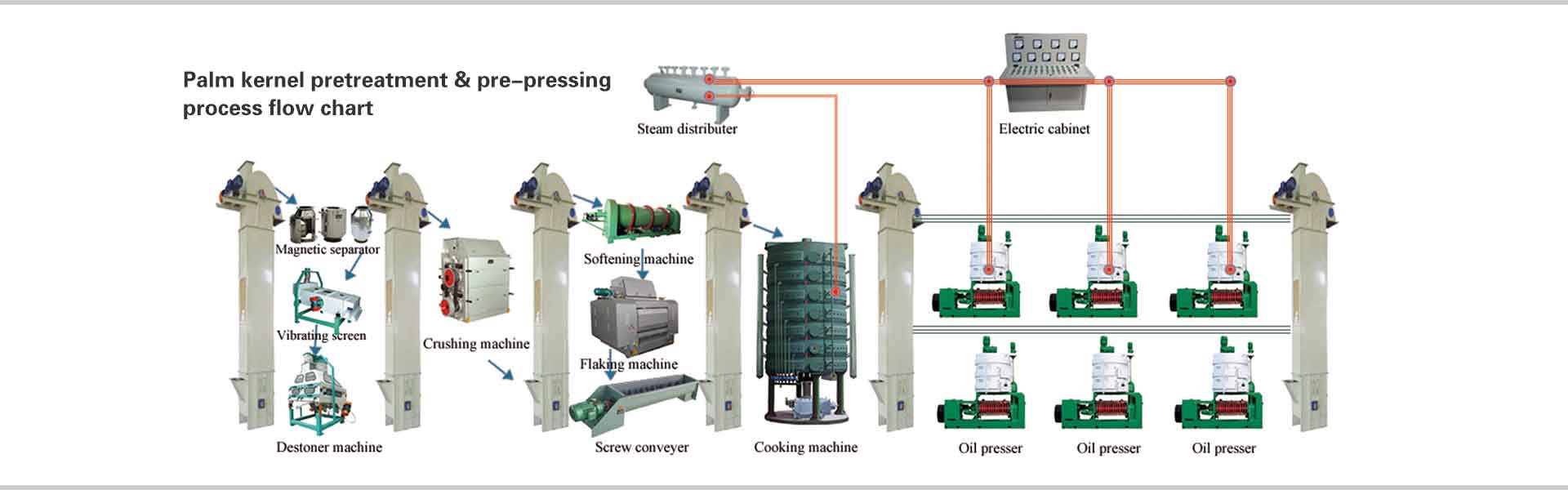

Production Process of Palm Kernel Oil Processing Machine:

The palm kernel expeller press machine is used in a variety of processes to produce the palm kernel oil. These include palm kernel pre-treatment,cleaning,crushing, flaking, steam conditioning, and screw pressing. During the pre-treatment process, the kernel is cleaned before it is ground to reduce its size. The machines separate the oil from solid impurities during the screw pressing process. The palm kernel that is obtained after expelling the oil is allowed to cool before storage. This cake is used as animal feed.

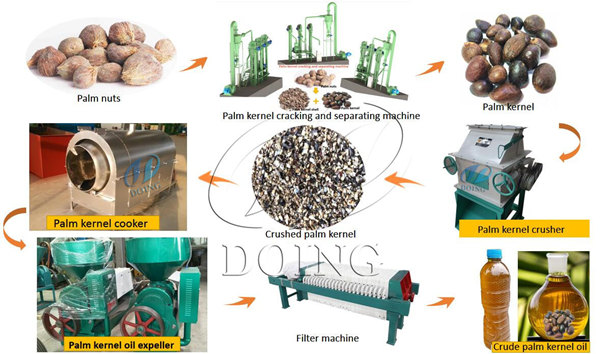

Palm kernel oil extraction process:

The palm kernel oil processing machines are used for three different extraction processes that include complete pre-treatment, partial pre-treatment, and direct screw-pressing.

Palm kernel oil extraction machine

Palm kernel oil extraction machine

Complete pre-treatment of palm kernel oil extraction process:

For complete pre-treatment, the machines clean, crusher, flaker, and steam condition the palm kernels before they are pressed. This process is usually carried out in plants that have a large capacity.

Partial pre-treatment of palm kernel oil extraction process:

The machines break down the palm kernels into small fragments before flaking them. Once the kernels are ground, the machines screw presses them to expel oil. Some of the machines are designed to cook kernels.

Direct screw pressing of palm kernel oil extraction process:

The palm kernel expeller press machine can also crush the kernels without going through any pre-treatment process. In such cases, the machines are designed to go through double pressing to make sure the oil is extracted efficiently.

Palm kernel expeller press machine

Palm kernel expeller press machine

Benefits of Using Palm Kernel Expeller Press Machine:

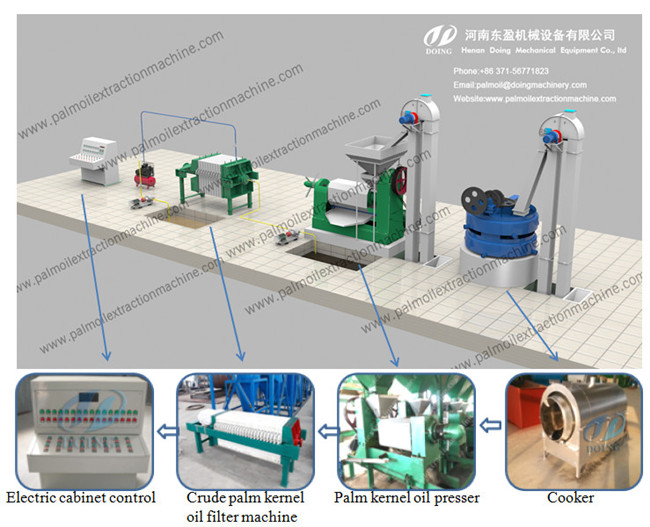

Ultimately, the expelled palm kernel oil contains a given quantity of "foots and fines 'which needs removing. Thereafter, the oil coming from the presses gets drained into a reservoir. After that, the palm kernel oil can be pumped either to the revolving coarse screen or to a decanter. The aim is to solid impurities. What follows is pumping the oil to filter press so that the remaining fines and solids can be removed. This ensures that clear palm kernel oil is produced before storage. The cakes that have been released from the presses are transported for bulk storage or bagging.

It takes a lot of effort to expel oil from the palm kernels. The palm kernel expeller press machine helps to make the palm kernel extraction process more efficient. They are a low investment and can be installed with ease. These palm kernel oil expeller press machine offer a high capacity that allows them to deliver several tones of oil each day. The cost of operating the machine is low. It takes a short period to extract palm oil using the machines and this enhancing a plant's productivity.

The palm kernel expeller press machines are made of alloy steel and their screw shafts are tested using an ultrasound to ensure efficiency. The bearings are heavy duty, which allows the machines to withstand several tones of palm kernel. This also helps to reduce wear and tear in the internal parts of the machine.

Palm kernel expeller press machine ensure low residual oil content once the cakes are pressed for a second time. They also consume less power compared to other types of machines, which makes them cost efficient. The use of palm kernel oil expeller press machine is necessary if a plant wants to maximize its oil extraction process. The machines are designed after specialized research to make sure that each one meets quality standards.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line