Palm oil processing in Nigeria

Industry news / Chat on line / Give me a price / Date: March 5, 2018

Palm oil processing description :

Palm fruit bunches

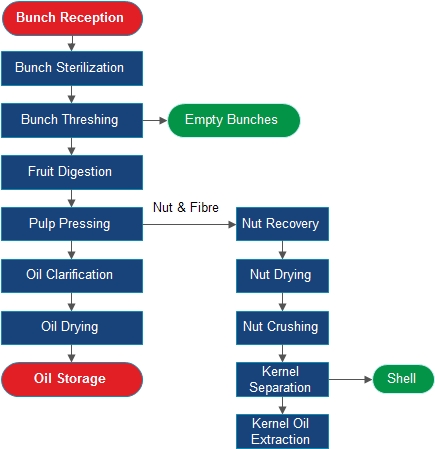

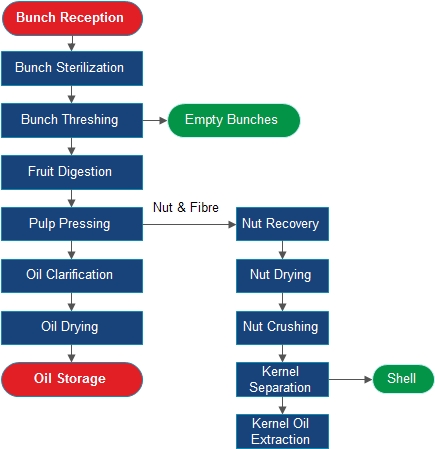

The oil winning process, in summary, involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil. The crude oil is further treated to purify and dry it for storage and export.

Large-scale plants, featuring all stages required to produce palm oil to international standards, are generally handling from 30 to 120tonnes of FFB/hr. The large installations have reception station,sterilization station, threshing station,digesting & pressing station and crude palm oil clarification station. Most processing operations are automatically controlled and routine sampling and analysis by process control laboratories ensure smooth, efficient operation.

Conversion of crude palm oil to refined oil involves removal of the products of hydrolysis and oxidation, colour and flavour. After refining, the oil may be separated (fractionated) into liquid and solid phases by thermo-mechanical means (controlled cooling, crystallization, and filtering), and the liquid fraction (olein) is used extensively as a liquid cooking oil in tropical climates, competing successfully with the more expensive groundnut, corn, and sunflower oils.

Extraction of oil from the palm kernels is generally separate from palm oil extraction, and will often be carried out in mills that process other oilseeds (such as groundnuts, rapeseed, cottonseed, soybean or copra). The stages in this process comprise cleaning machine ,crushing machine,softening machine,flaking machine ,cooking machine,pressing machine and extracting the oil using an oilseed expeller or petroleum-derived solvent. The oil then requires clarification in a filter press or by sedimentation. Extraction is a well-established industry, with large numbers of international manufacturers able to offer equipment that can process from 30-2000tpd.

Alongside the development of these large-scale fully mechanised oil palm mills and their installation in plantations supplying the international edible oil refining industry, small-scale village and artisanal processing has continued in Africa. For this, Henan Doing Mechanical Equipment Co.,Ltd developed and produced small scale palm oil processing machine with 1tph,2tph,3tph......10tph and single palm oil machine.

All palm oil equipments produced by Henan Doing Mechanical Equipment Co.,Ltd can realize mechanized operation.Next is the pictures of palm oil processing machine .

The general flow diagram is as follows:

Palm oil processing process

The pictures of small scale palm oil processing machine :

Palm fruit sterilizer

Palm fruit thresher

Palm fruit presser

Plam oil processing machine running video:

Palm oil production process with capacity 1tph,2tph,3tph,5tph

Palm fruit bunches

Large-scale plants, featuring all stages required to produce palm oil to international standards, are generally handling from 30 to 120tonnes of FFB/hr. The large installations have reception station,sterilization station, threshing station,digesting & pressing station and crude palm oil clarification station. Most processing operations are automatically controlled and routine sampling and analysis by process control laboratories ensure smooth, efficient operation.

Conversion of crude palm oil to refined oil involves removal of the products of hydrolysis and oxidation, colour and flavour. After refining, the oil may be separated (fractionated) into liquid and solid phases by thermo-mechanical means (controlled cooling, crystallization, and filtering), and the liquid fraction (olein) is used extensively as a liquid cooking oil in tropical climates, competing successfully with the more expensive groundnut, corn, and sunflower oils.

Extraction of oil from the palm kernels is generally separate from palm oil extraction, and will often be carried out in mills that process other oilseeds (such as groundnuts, rapeseed, cottonseed, soybean or copra). The stages in this process comprise cleaning machine ,crushing machine,softening machine,flaking machine ,cooking machine,pressing machine and extracting the oil using an oilseed expeller or petroleum-derived solvent. The oil then requires clarification in a filter press or by sedimentation. Extraction is a well-established industry, with large numbers of international manufacturers able to offer equipment that can process from 30-2000tpd.

Alongside the development of these large-scale fully mechanised oil palm mills and their installation in plantations supplying the international edible oil refining industry, small-scale village and artisanal processing has continued in Africa. For this, Henan Doing Mechanical Equipment Co.,Ltd developed and produced small scale palm oil processing machine with 1tph,2tph,3tph......10tph and single palm oil machine.

All palm oil equipments produced by Henan Doing Mechanical Equipment Co.,Ltd can realize mechanized operation.Next is the pictures of palm oil processing machine .

The general flow diagram is as follows:

Palm oil processing process

The pictures of small scale palm oil processing machine :

Palm fruit sterilizer

Palm fruit thresher

Palm fruit presser

Palm oil production process with capacity 1tph,2tph,3tph,5tph

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line