How to start a palm kernel oil processing business in Nigeria?

Industry news / Chat on line / Give me a price / Date: March 6, 2021

Nigeria is a world-renowned palm fruit tree planting area. The local large-scale planting and processing provides palm oil to all parts of the world. With the development of palm oil processing business, more and more people realized that starting palm oil processing business and palm kernel oil processing business is a viable option. Especially in recently years, there are many local oil palm plantation owners want to engage in the palm oil production industry, so as a professional palm oil processing machine manufacturer, I would like to share with you how to start palm kernel oil processing business in Nigeria.

How to start palm kernel oil processing business in Nigeria

How to start palm kernel oil processing business in Nigeria

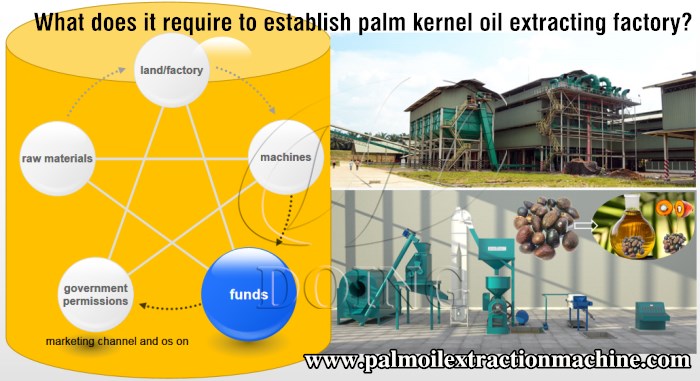

If you want to do palm kernel oil processing business in Nigeria, you must prepare from the following aspects: raw materials, factory, equipment, workers and others. Among all the influencing factors, the palm kernel oil processing machine is the most critical in the whole preparation process, the main reasons is follows:

1. Compared with equipment, the other aspects are easily solved locally.

2. The palm kernel oil processing machine quality and operation directly affect the efficiency and profit of the business.

Small scale palm kernel oil processing machine

Small scale palm kernel oil processing machine

Next i will take the palm kernel oil processing business as an example to tell you what machines are needed in palm kernel oil processing business.

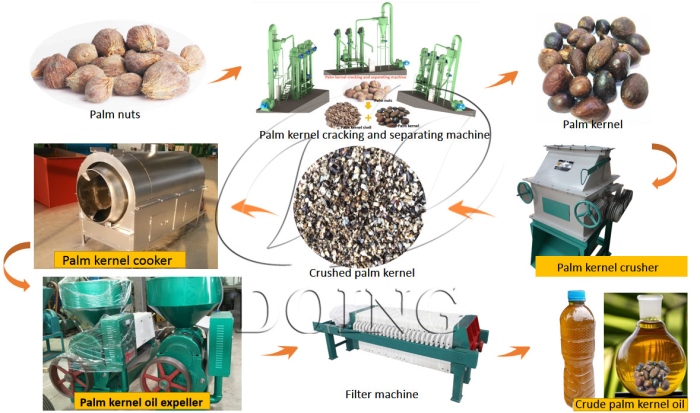

First of all, it is necessary to confirm whether the raw material is palm nuts or palm kernel. Because the raw material is different, the machine required is different. If the raw material is palm nuts, a palm kernel cracking & separation system is required to separate the palm kernel shell and palm kernel. And then use the palm kernel oil pressing equipment to squeeze the palm kernel input to obtain crude palm kernel oil, and finally use the palm kernel oil refining machine to process the crude palm kernel oil to obtain RBD palm kernel oil.

Palm kernel cracking and separating machine, palm kernel oil pressing machine and palm kernel oil refining machine are our important equipment, next i will introduce them to you one by one.

1) Palm kernel cracking and separating machine

Our palm kernel cracking & separation system is our patented product. The whole palm kernel cracking and separating system is consist of palm kernel cracker and palm kernel and shell separator machine. The palm kernel cracker machine uses the spacing between the beating rod and the tooth plate to break the palm nut to obtain a complete mixture of palm kernel and palm kernel shell. The palm kernel and palm kernel shell separator machine mainly use the working principle of fan and cyclones to separate the mixture of palm kernel shell and kernel. Finally the palm kernel is completely and efficiently separated, with a separation rate of 95%-97%. Believe it or not, our palm kernel cracking and separating machine can maximize the degree of automation and work efficiency, reduce the loss rate of raw materials, reduce production costs, and increase revenue.

Palm kernel cracking and separating machine

Palm kernel cracking and separating machine

2) Palm kernel oil press machine

Our palm kernel oil squeezing equipment( palm kernel oil press machine) can extract the oil in palm kernel to the greatest extent, and reduce the residual oil rate.

Small scale palm kernel oil press machine

Small scale palm kernel oil press machine

3) Palm kernel oil refining machine

Finally, our palm kernel oil refining machine can go through several steps of degumming, deacidification, decolorization and deodorization to help people get more cleaner edible palm kernel oil, which can also be used in other chemical industries.

Small scale palm kernel oil refining machine

Small scale palm kernel oil refining machine

In conclusion, before the start of palm kernel oil processing business, we must carefully select the relevant equipment. Henan Glory's palm kernel oil processing equipment is well-known in the palm oil production industry. Till now, we have helped many customers set up palm oil mill plant projects successfully and have received many good feedbacks. I believe that many local palm oil manufacturers in Nigeria have heard of our company.

All in all, Henan Glory Company is good at providing suitable palm oil processing machines for clients to meet their different needs. If you have special needs, you can get in touch with us by filling the contact form and we will get back to you with a quote or solution.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line