How to set up a palm oil mill that produces export quality palm oil?

Industry news / Chat on line / Give me a price / Date: March 25, 2020

Palm oils are the largest consumption, largest production quantities and physical volume of international trade oil. There are large need and market in the world. Thus more and more people are interested in setting up a palm oil mill that produce export quality palm oil. For people who are the first time to start the palm oil production business, they may be confused and don’t know how to do it. Here are some professional guidance and advise for how to set up a palm oil mill that produce export quality palm oil.

Setting up a palm oil mill plant is feasible for people in the areas where palm fruit is produced

Setting up a palm oil mill plant is feasible for people in the areas where palm fruit is produced

In general, you need to consider these aspects: raw material source, workshop building, government certification approve, funding, equipment and finished oil distribution channel.

For raw material FFB, palm tree are mainly located in Africa countries(Nigeria, Ghana, Tanzania, Ivory coast), Southeast Asia(Malaysia, Indonesia, Thailand) and central America and Northern South America. So people in these areas are easy to set up palm oil mill factory, because the raw materials are easier to get.

Palm fruit bunches is the main material of palm oil mill plant

Palm fruit bunches is the main material of palm oil mill plant

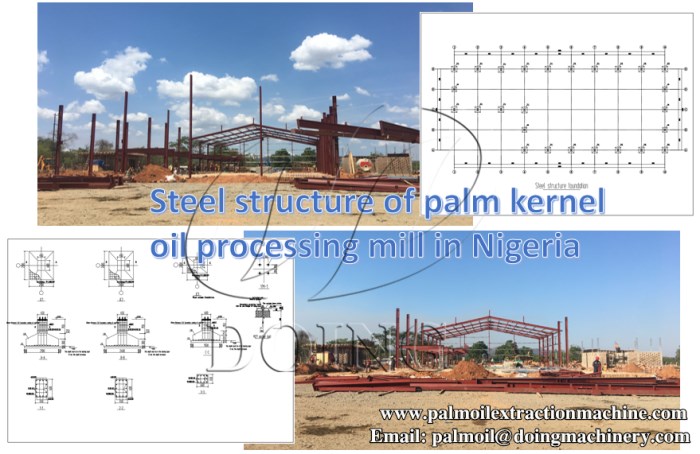

Secondly, you need to find existing workshop or new land to build workshop for put the palm oil processing machines. We will provide you workshop size for helping you choose suitable land. 【Related post: What factors should be considered when choosing the location of the palm oil mill? 】

You need to build a factory to put the palm oil processing machine

You need to build a factory to put the palm oil processing machine

After the workshop problem is solved, you need to solve the license problem. You need to check what kind of permissions or certificates you need to apply from government for setting up the palm oil mill plant in your countries. For example, our customer in Tanzania need to prepare four certificates: they are land/building certification, building permits, construction inspections certification issued by food and drug administration, environmental impact certification.

Then it is the budget for the palm oil mill project. When setting up a palm oil mill, you need to consider the cost of raw material, building factory cost, labor cost, shipping cost and so on. You can invest all by yourself or find partner to invest together or make a loan from bank.

Once the above problems are solved, the next problem you need to solve is to find a suitable palm oil processing machine supplier who can offer you good quality palm oil machines and design suitable technical process. In general. You can offer the exported finished product palm oil specification standard to supplier, then they will design technical project to reach your requirement. 【Related post: How to choose suitable palm oil processing machine supplier?】

Small scale palm oil processing machine produced by Henan Doing Company

Small scale palm oil processing machine produced by Henan Doing Company

Our Henan Doing Mechanical Equipment Co.,ltd is a professional palm oil machine manufacturer in China. We can offer palm oil processing machine with different capacity, such as 1-5t/h small scale palm oil mill, 10-30t/h medium scale palm oil mill plant and 30t/h-120t/h palm oil mill plant. Till now, we have successfully installed many palm oil mill plant projects in different countries, such as Nigeria, Ghana, Malaysia, Mexico ,Indonesia, Thailand and so on. We are glad to design suitable palm oil mill project and offer good quality machine for you. We sincerely look forward to working with you.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line