HomeNewsIndustry newsWhat should be paid attention to when buying palm kernel oil processing equipment?

HomeNewsIndustry newsWhat should be paid attention to when buying palm kernel oil processing equipment?

What should be paid attention to when buying palm kernel oil processing equipment?

Industry news / Chat on line / Give me a price / Date: February 8, 2023

Palm kernels are part of the palm fruit and contain 50-55% oil in the kernel. Since palm kernel is very hard, if you want to extract palm kernel oil out, you need to buy palm kernel oil processing equipment which is different from other oil processing equipment.

Palm kernel oil processing machine

Palm kernel oil processing machine

The following is some suggestions for you when buying palm kernel oil processing equipment.

1. Select good equipment supplier

First of all, we must consider which supplier to find to purchase equipment, whether it is a trader or a direct manufacturer. We suggest that you go directly to the manufacturer, because not only the price is lower, but also the after-sales service is more guaranteed. Henan Glory Company has been a palm kernel processing equipment manufacturer for more than ten years.

2. Provide clear requirement

To clarify what your raw material is and the palm kernel oil standard you want to get in the end, choose equipment according to daily processing capacity, budget, plant size, etc.

When your raw material is palm nut or palm kernels, the processing required is different. If your raw material is palm nut, we recommend that you use palm kernel separation equipment to process the palm nut first to get palm kernels. Secondly, figure out whether the final product you want to get is crude palm kernel oil or refined palm kernel oil. If you want refined palm kernel oil, after processing according to the general process of palm kernel oil, you need to add refining equipment to obtain refined palm kernel oil. Third, figure out your daily processing capacity, and choose small, medium and large scale palm kernel oil processing equipment according to the daily processing capacity. Furthermore, consider your budget and plant area to choose the right palm kernel oil processing equipment and production line. Henan Glory has a professional team that can cover multiple links such as consultation, scheme production, installation guidance and site planning, and can help customers solve problems in the whole process from the beginning of design to installation and use.

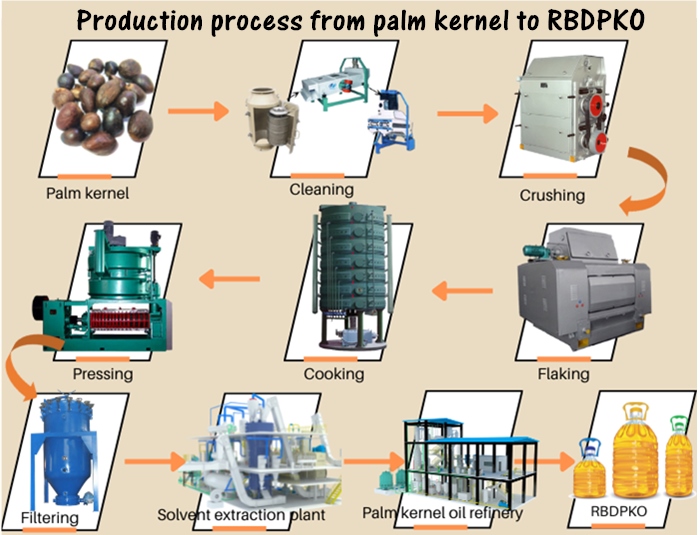

3. Learning about the palm kernel oil processing process

The complete processing process of palm kernel oil is fiber separator, palm kernel separation system, crusher, cooker, palm kernel oil press, plate and frame filter. Different suppliers can provide different processes, and you can choose the required equipment according to your actual needs. In addition, Henan Glory can provide large, medium and small palm kernel oil production lines. We have professional engineers who can help design the production line and install according to your actual needs.

4. Comparing the price, quality and raw materials of palm kernel oil processing equipment

Generally, customers will pay attention to price when purchasing, but it is not comprehensive enough to only pay attention to price. While paying attention to the price, it is necessary to know more about the product quality of the equipment, such as material, service life, after-sales guarantee, etc., and compare various aspects to choose the appropriate palm kernel oil processing equipment.

5. Select suitable palm kernel oil processing equipment

The following mainly recommends the selection of suitable palm kernel oil processing equipment from the palm kernel raw material and daily processing capacity.

From the raw material and process:

Palm nuts processing: If your raw material is palm nut, we recommend you to use fiber separator to get clean palm nuts. Then use a cracker to crack palm nuts, you can get the palm kernels. If you have a big processing capacity, you can use palm nuts cracker and separator system, the cracking and separating rates need to be high so you get clean plam kernels. DOING palm nuts cracker and separator system’s cracking rate is 96-98%, the separating rate is 99%.

Palm kernel processing: The palm kernel is very hard, so we recommend using a crusher to break the kernel into small pieces. Then use a cooker to adjust the moisture and temperature. Generally, the moisture of palm kernels should reach about 13%, which can achieve the best pressing effect.

Palm kernel pressing: Plam kernel is not like other oil matrial, the screw of its oil press needs to be very strong. DOING palm kernel oil expeller machine's screw adopts 45# alloy steel, very wear-resistant. We recommend choosing the oil press with high quality screw material, higher efficiency, higher oil yield, thus increasing revenue. After you get the crude palm kernel oil, use a filter to remove the impurities from the oil, then you can get clean crude oil.

From the processing scale:

If your daily processing capacity is 5-30 tons, we recommend you to choose the small and medium-sized palm kernel oil processing line. The main process is palm kernel fiber separation, kernel shell separation system, crusher, cooker, palm kernel presser and filtering.

If your daily processing capacity is 30-200 tons, the large palm kernel oil processing line is suitable for palm kernel. The main process is fiber separation, kernel shell separation system, crusher, cooker, palm kernel pre-pressing, oil cake and sovlent extration system.

The above is five main attentions when buying palm kernel oil processing equipment. If you have any need on processing palm kernel oil, feel free to contact us.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line