Deodorization technology of palm oil

Company news / Chat on line / Give me a price / Date: June 23, 2016

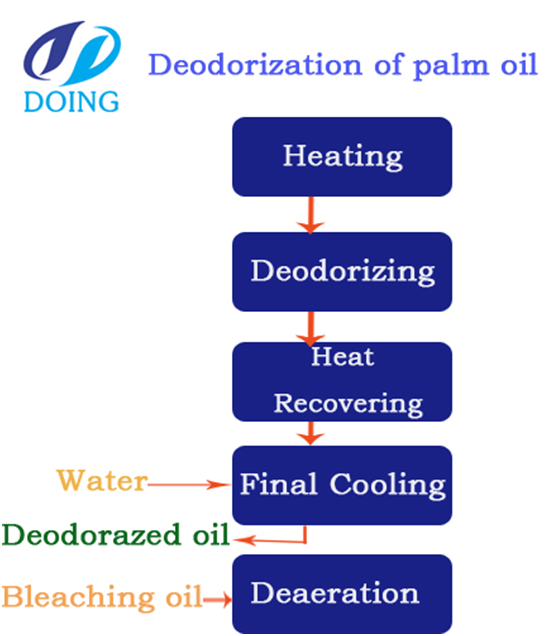

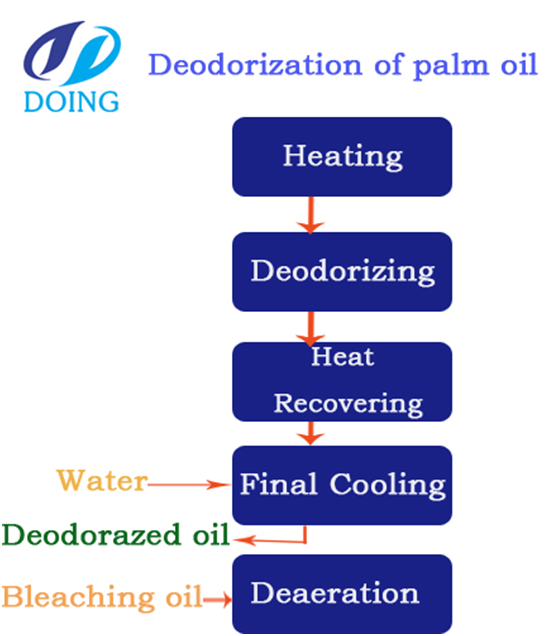

Deodorization is actually a stripping process in which a given amount of a stripping agent (usually steam) is passed for a given period of time through hot palm oil at a low pressure. Hence, it is mainly a physical process in which various volatile components are removed. However, since it is usually carried out at high temperature (> 200°C), some chemical, thermal effects may take place as well.

Palm oil deodorization

Palm oil contains various components, each with its specific volatility. In physical refining, it is mainly free fatty acids (FFA) that need to be stripped. Apart from FFA, other volatile components, either valuable (tocopherols, sterols, etc) or unwanted (off-flavors, pesticide residues, light polycyclic aromatic hydrocarbons, dioxins, etc), are also removed during deodorization.

Palm oil deodorization

Palm oil contains various components, each with its specific volatility. In physical refining, it is mainly free fatty acids (FFA) that need to be stripped. Apart from FFA, other volatile components, either valuable (tocopherols, sterols, etc) or unwanted (off-flavors, pesticide residues, light polycyclic aromatic hydrocarbons, dioxins, etc), are also removed during deodorization.

| Deodorized palm oil | |

| Quality parameter | Physical refining palm oil |

| FFA (%) | 85-90 |

| Tocopherols (%) | 0.15-0.30 |

| Sterols (%) | 0.2-0.4 |

| Squalene (%) | 0.5-1.0 |

| Neutral oil (%) | 6-9 |

| Distillate flow (%) | 0.3-1.0 |

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line