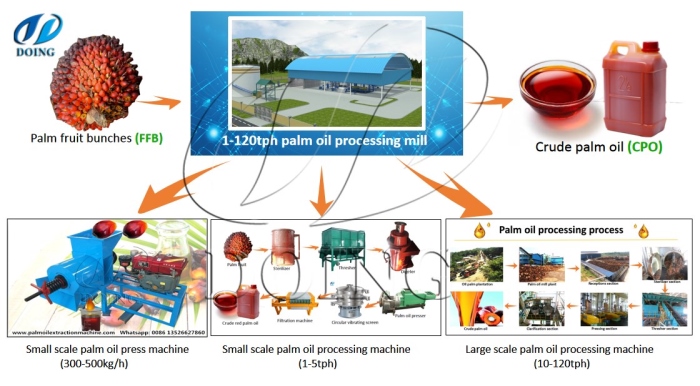

A brief introduction of palm oil production line

Company news / Chat on line / Give me a price / Date: August 30, 2018

Henan Glory Company is a professional palm oil production machine manufacturer. We could offer customers palm oil production lines with simple, small and medium and large scale. Here are some brief introduction about these palm oil production lines.

1-120tph palm oil production line

1-120tph palm oil production line

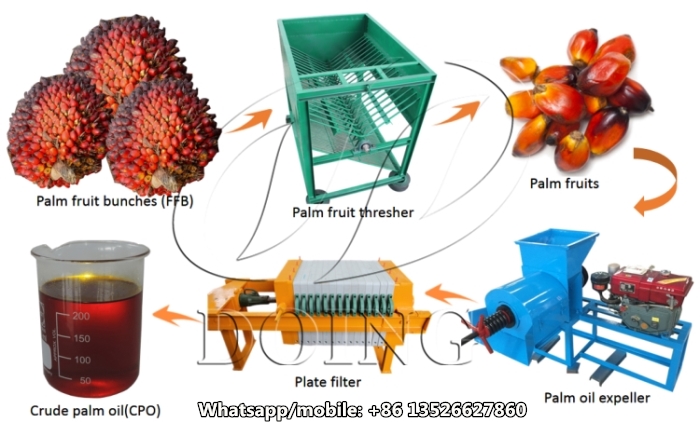

Simple palm oil production line

500kg/h-2t/h palm oil production line

500kg/h-2t/h palm oil production line

This line is suitable for 500kg/h-2t/h processing capacity and it includes the following steps:

1. Simple type threshing of palm oil production: Putting palm fruit bunches into thresher is to separate palm fruit from fruit bunches. In order to achieve a better fruit threshing effect, it is best to boil the palm fruit bunches in hot water before threshing. This step need some laborers to help better operate in order to get high efficiency and better effect of threshing.

2. Pressing of palm oil production: Using screw palm oil presser extracts oil from palm fruit. In this step, Henan Glory Company can provide two types screw pressers for you. One is 500kg/h single palm oil presser, which has diesel and motor power systems, suitable for different power conditions. The other is 1-2tph double screw oil presser, which can be suitable for production line and has low residual oil rate and high efficiency.

3. Filtering of palm oil production: 500-1000kg/h plate filter is used to remove impurity from crude oil and get cleaner crude oil, widely used with good performance. There is another option for streamlining production line. The automatic temperature-controlled vacuum filtration integrated oil press can realize one machine for two purposes, and the same machine can complete the pressing and filtering. In all, this line has advantages of lower cost and become a good choice for customers having limited budget on machines.

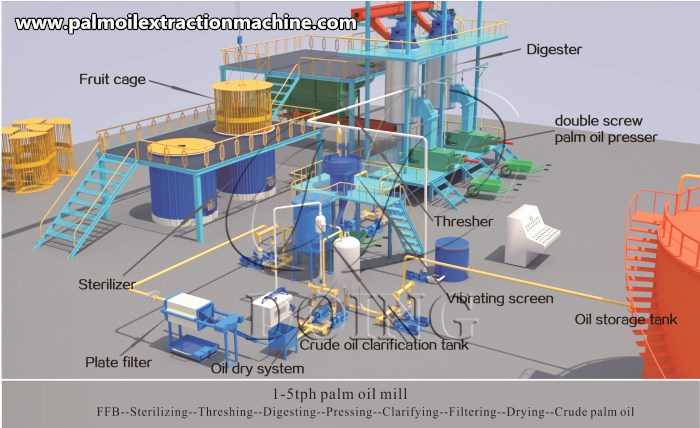

Small scale palm oil production line

1-5tph palm oil production line

1-5tph palm oil production line

This line is suitable for 1-5t/h processing capacity and it includes the following steps:

1. Sterilization station of palm oil production: Putting the palm fruit bunches into the sterilization tank for cooking is to increase the humidity of the fruit, which is beneficial to the separation of the fruit from the fruit bunches. Additional, it destroys the activity of the fat-decomposing enzyme and prevents the content of free fatty acids (FFA) from increasing, so as to slow down rancidity.

2. Threshing station of palm oil production: Conveyor scrapers will transport the fruit bunches in the fruit cages to the thresher. The threshing station usually adopts a drum type threshing machine, which is generally 2.5 meters long. In this way, palm fruit will be better separated from the palm fruit bunches.

3. Digesting station of palm oil production: Conveying auger will transport these palm fruits to the palm fruit digester. The pulp is stirred and broken in the digester tank and becomes finely divided, which can improve the oil yield. In addition, a portion of the oil produced during the digesting process can be collected in the lower oil collection tank.

4. Pressing station of palm oil production: The oil presser is generally placed under the digester to facilitate timely pressing. Henan Glory Company can provide different types of pressing machines which can be chosen according to processing capacity or your requirements.

5. Oil Clarification station and Filtering of palm oil production: For the filtration stage, a vibrating screen, an crude oil clarification tank and a plate filter are generally configured to filter different impurities in the crude oil. Using the latest technology and under the premise of ensuring the quality of oil, the purified crude palm oil can be provided after sedimentation, filtration and separation.

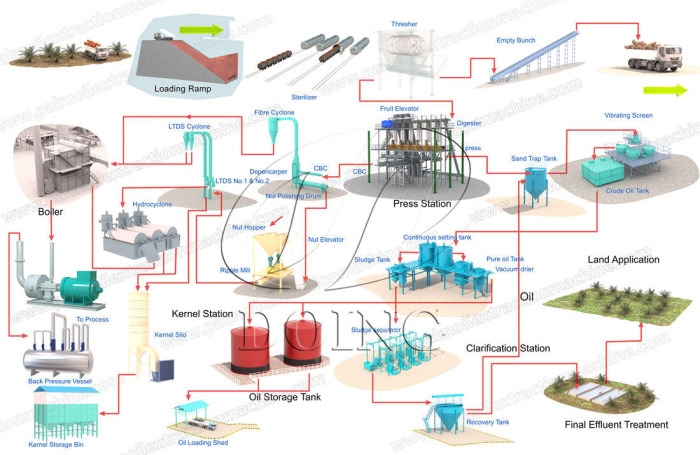

Medium and Large scale palm oil production line

10-120tph palm oil production line

10-120tph palm oil production line

This line is suitable for processing capacity from10t/h to 120t/h. It mainly includes 9 sections:

1. Raw materials storage section of palm oil production: Fresh palm fruit bunch must be first measurement recorded by the pound into the plant, then unloaded to loaded fruit slopes and stored.

2. Sterilizing section of palm oil production: Fresh palm fruit bunch are airtight sterilized in sterilizer. The purpose is to prevent enzymes broken down, avoiding FFA content in oil further increase; easy threshing machinery; pretreatment peel, prepared for the follow-up processing; pre-conditioning stone, reducing the damage kernel.

3. Threshing section of palm oil production: The purpose of threshing is to separate oil palm fruit from the fruit bunch through strong vibration.

4. Palm oil pressing section of palm oil production: Before pressed, oil palm fruit first be carried out cooking, sterilized fruit must be re-heated to make the pulp soft and damage pulp cell structure. Then enter into continuous screw press.

5. Palm oil clarification section of palm oil production: Machine-pressed crude oil first diluted with water washing, the fiber material removed from the oil through settlement and filtration, and then carry out continuous settlement.

6. Finished crude palm oil is stored in storage tanks.

7. Fiber separation section of palm oil production: Press cake broken by breaking screw conveyor and then transported into the fiber separation air net and fiber polishing roller for fiber separating.

8. Kernel recovery section of palm oil production: After separation, shell is sent to the warehouse for temporary storage, as boiler room fuel when necessary; Dried kernel is sent to kernel storage warehouse for storing.

9. Sewage treatment section of palm oil production: Pool sewage treatment system is the most used and effective treatment.

If you are interested in palm oil production line, please feel free to contact me.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line