How to filter crude palm oil? What machines will be used?

FAQ / Chat on line / Give me a price / Date: April 20, 2020

Palm oil filtration process is very important process in the palm oil processing process, it refers to remove the unwanted impurities from the crude palm oil, such as fibers, sands, water and so on. Typically, the scale of the palm oil mills different, the process and machines used to filter crude palm oil will be different. Next i will introduce you to the steps of palm oil filtration and the equipment used.

In the large palm oil mills of Indonesia and Malaysia, there are five processing steps to filter crude palm oil, they are:

1) Use vibrating screen to remove the fibers;

2) Use clarification tank to settle for a period of time to remove the large impurities;

3) Next use decanter to recover the palm oil in the sludge;

4) The next step is to use plate filter to remove the small impurities;

5) Finally, we need to use vacuum dryer to remove the water in the palm oil.

After the above steps, we can get cleaner red palm oil, which is more easy to store and have high value.

Clarification station of large scale palm oil mill

Clarification station of large scale palm oil mill

In the very small palm oil mills of Africa, they have no modern machines, and the capacity is not big enough, they use the local traditional method to remove the impurities and water in the crude palm oil. The Africa local crude palm oil filter method is water boiling. Along with the palm oil processing industrial developing, this method can not meet the demands of the modern palm oil mills. To help more African people efficiently get clean red palm oil. We Henan Doing Company's engineers special designed the new type palm oil filtration process depending on the large palm oil mill technology of Indonesia and Malaysia.

Nigeria local traditional crude palm oil filtration method

Nigeria local traditional crude palm oil filtration method

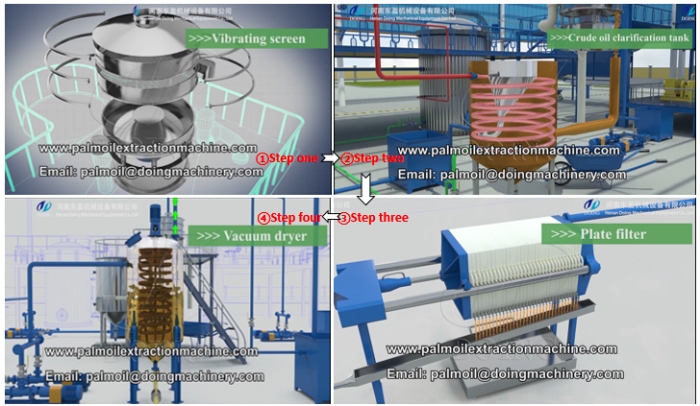

Similar to the Indonesia Malaysia large palm oil mills, our new type palm oil filtration process also includes the following machines, there are vibrating screen, clarification tank, plate filter and vacuum dryer. The detailed filtering process is as follows:

Crude palm oil clarification machine

Crude palm oil clarification machine

The first step is vibrating screen, the crude palm oil will be pumped into this machine, when the vibrating screen is working, the fibers will leave on the screen, and the palm oil will pass screen and flow to the buffer tank.

The second step is oil clarification, the clarification tank has the special inner structure. Which makes the clean palm oil come out from the top, and dirty palm oil drop in the bottom. Even this part can remove some impurities, but there are still some tiny impurities in the crude palm oil.

So the third step is plate filter, by using this filter most impurities will be removed, the oil is very clean.

After completing the above operation, most of the impurities in palm oil have been removed. Before packing, we need to finish the last step—— remove the water in the palm oil. Because if don’t dry the palm oil, it just can be stored a short time. The water will make the CPO go rancidity. To protect the palm oil no oxidation, we use the vacuum dryer to dry palm oil. In other words, the palm oil will be dried under the vacuum conditions.

Palm oil filtration steps of new type palm oil mill plant

Palm oil filtration steps of new type palm oil mill plant

The above is the introduction of crude palm oil filtering methods and filtering steps, but they only the brief introduction, there are still more knowledge will be involved in the crude palm oil filtration process. If you want to get cleaner palm oil in your palm oil production process, welcome to contact us.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line