How does the palm oil refinery plant work?

FAQ / Chat on line / Give me a price / Date: December 31, 2019

Normally, if you want to turn palm oil into refined palm oil, the palm oil refinery plant is essential. But do you know how does the palm oil refinery plant work? To refine red palm oil, there are four steps to do: degumming, deacidification, decolorization and deodorization. These four steps of palm oil refining processes are to remove the gum, deep color, odor and FFA in red palm oil, and purify crude palm oil to RBD palm oil.

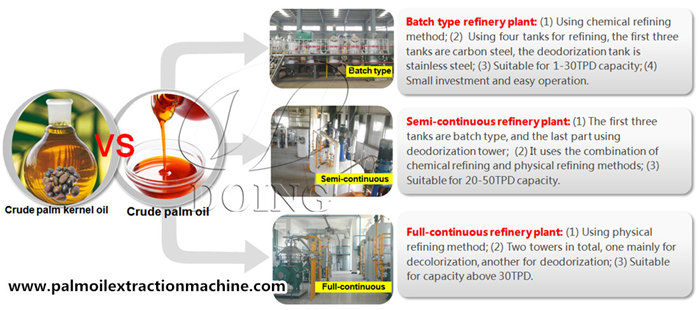

There are three type palm oil refinery plant: batch type, semi-continuous type and fully continuous type

There are three type palm oil refinery plant: batch type, semi-continuous type and fully continuous type

Because of different kinds of palm oil refinery plant have different palm oil refining process, different equipment will be used, so firstly you should know what kinds of palm oil refinery plant can be chose. There are three types of palm oil refinery plant: 1-10tpd batch type palm oil refinery plant, 10-30tpd semi continuous palm oil refinery plant and 30-600tpd fully continuous palm oil refinery plant. Next, let's learn each type palm oil refinery plant works.

1. Batch type palm oil refinery plant

Batch type palm oil refinery plant is often with the input capacity of 1-10 TPD and uses chemical palm oil refining method. There are one reaction tanks for each step in palm oil refining process, through adding something to remove the impurities out.

[Related post: Small scale palm oil refinery plant]

Batch type palm oil refinery plant successfully installed in Nigeria(Click here to learn Nigeria palm oil refinery plant projcet)

Batch type palm oil refinery plant successfully installed in Nigeria(Click here to learn Nigeria palm oil refinery plant projcet)

The following is each machine function of batch type palm oil refinery plant:

Refining pot: to remove gum and impurities from crude oil, and using alkali to neutralize acid inside crude oil

Decolorization pot: To move the pigment in the oil.

Deodorization pot: To move the bad smells in the cooking oil.

Conductive oil stove: It is used to provide the heat for the whole batch type cooking oil refinery plant process.

Vacuum pump: The function of batch type cooking oil refinery plant is to provide vacuum for decolorization and deodorization.

Air compressor: It will dry the white clay after absorb the pigment in the oil.

Steam generator: To generate the steam for the deodorization pot.

2. Semi-continuous type palm oil refinery plant

The semi-continuous type palm oil refinery plant is suitable for the capacity from 10-30TPD. It can uses the combination method of chemical refining and physical refining. The first three tanks are same as the batch type palm oil refinery plant, but the fourth step -- deodorization is different. It's a deodorizing tower which can continuously work.

Semi-continuous palm oil refinery plant successfully installed in Indonesia(Click here to learn Indonesia palm oil refinery plant project)

Semi-continuous palm oil refinery plant successfully installed in Indonesia(Click here to learn Indonesia palm oil refinery plant project)

The following is each machine function of semi-continuous palm oil refinery plant:

Refining pot: to remove gum and impurities from crude oil, and using alkali to neutralize acid inside crude oil

Decolorization pot: To move the pigment in the oil.

Deodorization tower: The decolorized oil is subjected to steam distillation under condition of high temperature and vacuum to remove bad smell, free fatty acids and other undesired minor components.

3. Full-continuous type palm oil refinery plant

The full-continuous type palm oil refinery plant normally uses dry type physical refining technology. This is the highest configuration in the palm oil refining, suitable for the palm oil refinery plant with input capacity from 30TPD to 600TPD. For full-continuous type palm oil refinery plant, not only deodorization tank changed to tower, decolorization tank also changed to tower. And degumming step will together with decolorization step. de-acid part will be together with deodorization step in tower.

[Related post: 50tpd continuous palm oil refinery plant]

100tpd fully continuous palm oil refinery plant successfully installed in Kenya(Click here to learn Kenya palm oil refinery plant project)

100tpd fully continuous palm oil refinery plant successfully installed in Kenya(Click here to learn Kenya palm oil refinery plant project)

The following is each machine function of full-continuous type palm oil refinery plant:

1. Degumming Section:

Palm oil degumming section uses washing method to separate soap residual from mixing oil, providing preparation for next step palm oil refinery process.

2. Decolorization Section:

Palm oil decolorization section is mainly used to remove oil pigment, residual soap and metal ions during palm oil refining process.

3. Deacidification and deodorization Section:

Generally speaking, deodorization process is the final stage in palm oil refining process. During dry type palm oil refining process, the deodorization tower can achieve two function simultaneously, removing FFA and other odorous substances from the oil.

Doing Company has been specialized in palm oil refinery plant for decades. And our palm oil refinery plant's technology and quotation are both our advantages to compete with other companies. If you are interested in palm oil refinery plant and palm oil refining technology , please feel free to contact us. Our professional engineers can help you design and install palm oil refinery plant projects according to your capacity and requirements.

contact us

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line