Palm Oil Mill Plant

Palm oil mill plant video

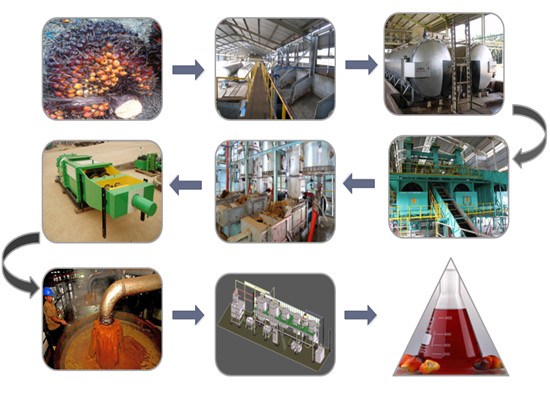

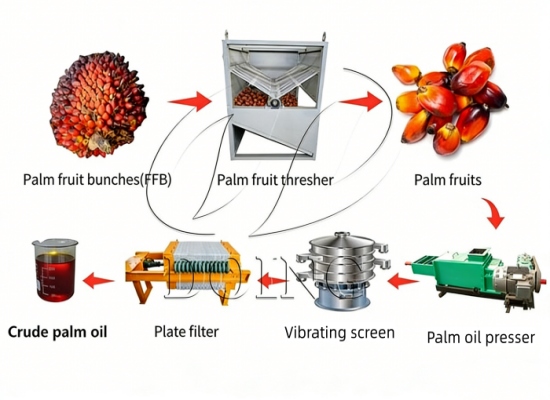

The above video is 1-5tph small scale palm oil processing machine 3D animation, from this video, we can know that what machines will be used in palm oil extraction process and the detailed palm oil processing steps.

Palm Oil Mill Plant Project

-

2tph Palm Oil and Palm Kernel Oil Processing Machines Project in Nigeria

-

3tph palm oil pressing line and palm kernel oil processing equipment project successfully installed in Jinja, Uganda

-

5TPH palm oil pressing line project in Liberia

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

Palm oil extraction technology support FAQ

A:Fractionated palm oil, a versatile derivative of crude palm oil, is used in the global food, cosmetics, and industrial sectors. Henan Glory can provide you with palm oil fractionation equipment to help you expand your revenue streams.

A:The clarification station in large palm oil mills includes three key stages—impurity removal, clarification & separation, and sludge recovery—and converts the pressed oil-water-fiber mixture into pure, stable commercial-grade crude palm oil.

A:You may have many questions when considering investing in palm kernel oil extraction machines. To help you make an informed decision, we have compiled some frequently asked questions, which will be answered in this article.

A:Henan Glory's professional vegetable oil refining machines deliver efficient degumming, deacidification, decolorization and deodorization—removing impurities and hazards, boosting oil quality, cutting costs, and supporting batch-to-continuous production.

NEWS

Company News

Industry News